Post Requirements

Post Requirements

Post Requirements

Post Requirements

产品参数

The VOMM dryer simultaneously uses the radial rotation of the turbine and the axial flow of the process circulating gas, so that the wet sludge entering the drying chamber is quickly crushed and granulated.

A thin turbulent layer of gas and solid mixture is formed, and the fluidized sludge particles quickly obtain enough heat energy from the drying chamber wall and process circulating gas in a very short time (2-3 minutes), and are continuously dried in a safe and controllable inerting environment.

At the same time, the turbulent condition of fluidization and granulation is more conducive to the accurate control of the temperature and humidity of the sludge at the outlet of the drying chamber by simple and traditional sensing means. Even when the input sludge moisture content changes, the output sludge dryness can be kept constant, and the whole process can realize intelligent regulation and automatic production.

产品描述

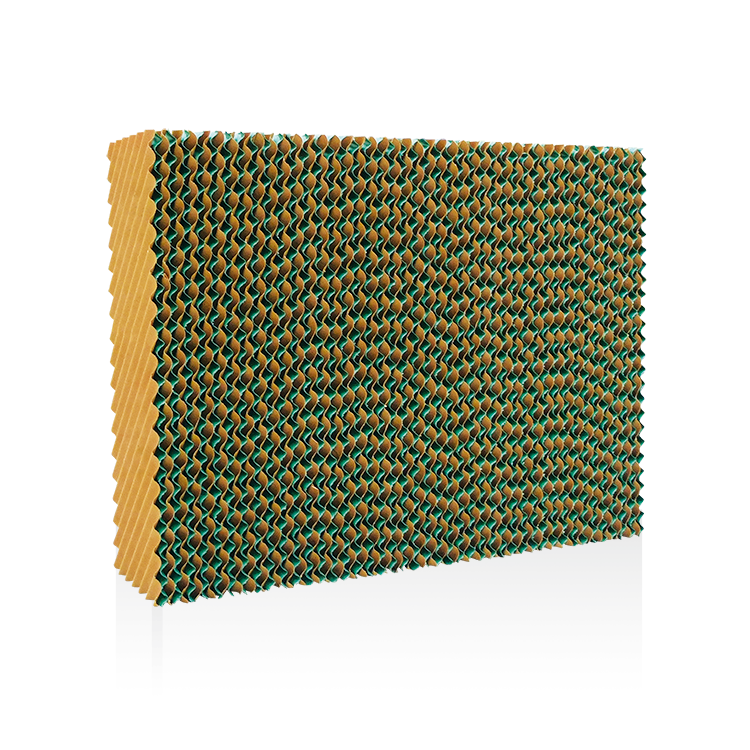

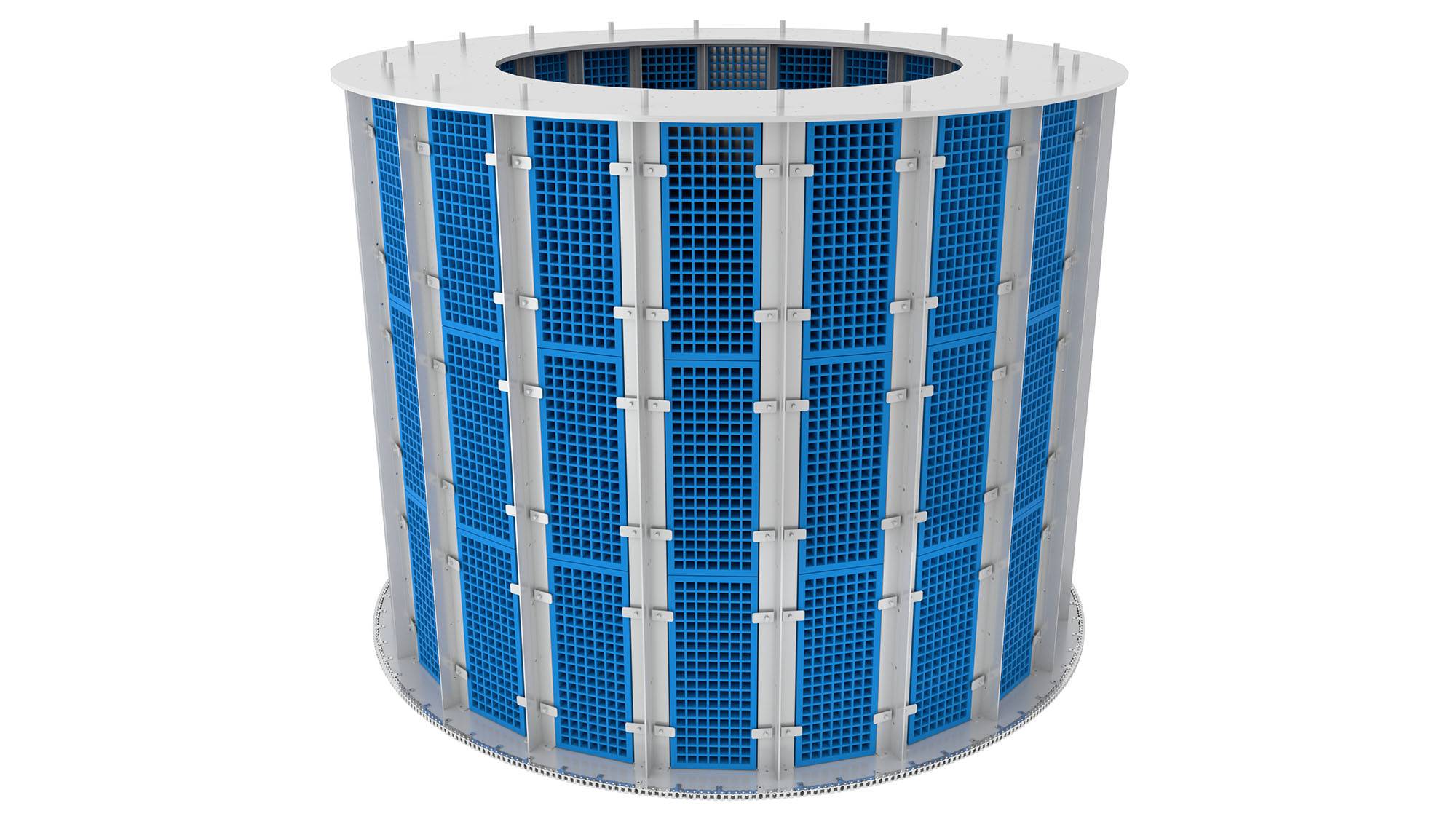

VOMM涡轮技术基于通过涡轮的作用在高湍流中形成湿产品薄膜。干燥过程结合了待干燥材料上热夹套(传导)和热工艺气体(对流)的热交换。

干燥室是一个静止的圆柱体,涡轮以非常高的速度旋转,并将湿产品离心到干燥器的圆柱形内壁上。产品在2-3分钟后以所需的干燥度与热工艺气体和蒸汽并流排出。无需准备材料。

VOMM 设备由 PLC 完全自动化和管理,并配备了所有必要的仪器来连续检查和控制主要工艺参数(温度、压力、流速等)。

VOMM技术的主要应用

- 半干化、全干化市政污泥、工业污泥、沼渣

- 有机废物(市政固废餐厨垃圾)干燥制作再生燃料

- 废液/渗滤液的深度浓缩、结晶

- 医疗废弃物(危废)集中灭菌消毒

- 固体废物干化提升热值LCV

- 化工和制药行业的连续热处理

VOMM技术的主要优势

- 市场上最低的能源和运营成本

- 无失控排放,因为这是一种闭环技术

- 工艺中氧气含量低于1-2%(闭环技术)

- 市场上最安全的技术

- 减小了总体尺寸

- 合同和履约保函保证每年8000小时的工作时间和20年的运营时间

Search

Search