Post Requirements

Post Requirements

Post Requirements

Post Requirements

产品描述

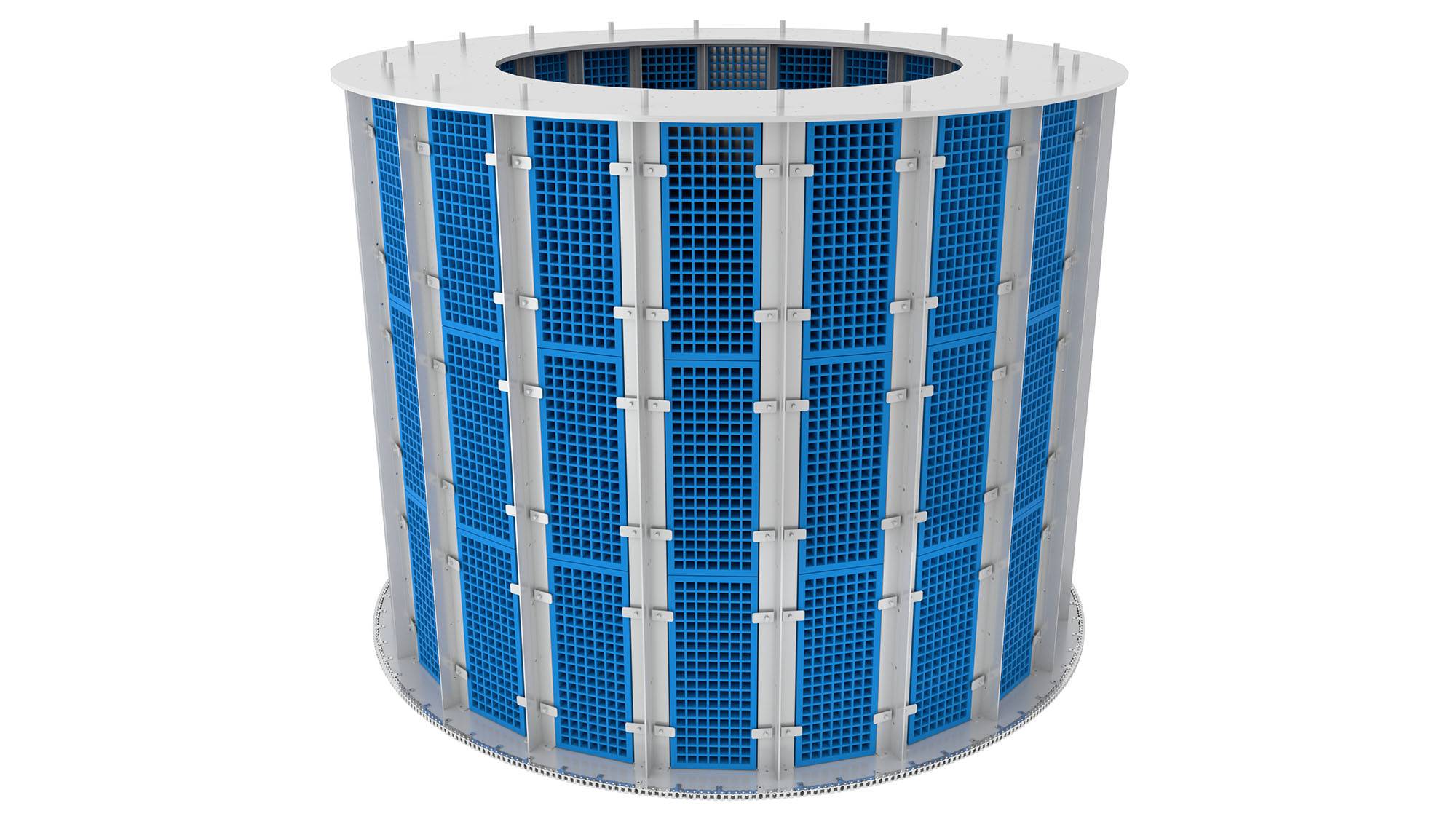

VOMM Turbo technology has been successfully applied to the continuous sterilization of medical waste to convert it into non-hazardous waste

Sterilization is based on the concepts of time, temperature and steam. In the presence of 170 ° C steam, the infected waste is kept at a temperature of >151 ° C for 15 minutes.

The process is a continuous process rather than a batch process. The waste is first continuously crushed and then disinfected in the VOMM continuous disinfection chamber (turbine sterilizer) by the combined action of steam and a rotating shaft equipped with stirring blades. In the turbine sterilizer, the waste is dried before export

The humidity of medical waste is on average 30%, and VOMM technology reduces the humidity below 10%, reducing the weight by 20%.

Due to the crushing stage, the volume is reduced by a factor of 4/5

The calorific value of chopped, sterilized and dried medical waste averages 6,000 to 7,000 kcal/kg.

Compared to other technologies, VOMM technology is

safer

Lower energy consumption

Lower pressure

Dryer Final product (humidity less than 10%)

Higher sterilization effect

Higher low calorific value (LCV) of the product for use as waste-derived fuel (RDF)

Small product size

VOMM manufactures and delivers the largest disinfection plant in Europe: the Arenzano plant, which has a capacity to treat hospital waste of 24,000 tons per year

VOMM disinfection equipment is modular and its capacity ranges from 500 kg/h to 3.000 kg/h

Search

Search