Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

product information

Hydraulic stations, also known as hydraulic pump stations, are independent hydraulic devices. It supplies oil according to the requirements of the main engine. It also controls the direction, pressure and flow of hydraulic oil flow. It is suitable for various hydraulic machinery where the main machine and the hydraulic device can be separated. After purchasing, users only need to connect the hydraulic station to the actuator (oil cylinder or oil motor) on the main machine with oil pipes, and the hydraulic machinery can realize various specified actions and work cycles.

The hydraulic station is composed of a system device, an integrated block or valve combination, an oil tank, and an electrical food supply. The functions of each component are:

Pump device-equipped with a motor and oil pump, is the power source of the hydraulic station, converting mechanical energy into pressure energy of hydraulic oil.

Integrated block-It is assembled from hydraulic valve and channel body. Adjust the direction, pressure and flow of hydraulic oil.

Valve combination-plate valves are installed on vertical plates and connected to pipe bases behind the plates, with the same function as integrated blocks.

Fuel tank-a plate-welded semi-enclosed container, which is also equipped with an oil filter screen, air filter, etc., for storage, oil cooling and filtration.

Electrical boxes-come in two forms. One is equipped with a terminal board with external leads; the other is equipped with a complete set of control appliances.

Working principle of the hydraulic station: The motor drives the oil pump to rotate, and the pump absorbs oil from the oil tank and supplies oil, converting mechanical energy into pressure energy of hydraulic oil. Hydraulic oil realizes direction, pressure, and flow adjustment through integrated blocks (or valve combinations), and then passes through external pipelines and into the oil cylinder or oil motor of the hydraulic machinery, thereby controlling the direction change of the hydraulic machine, the magnitude of the force and the speed., promote various hydraulic machinery to do work.

Structural form and main technical parameters of hydraulic station

Structural form: It is mainly distinguished by the structural form, installation position and cooling method of the pump device. According to the structural form of the pump device, the installation position can be divided into three types:

1. Upper-mounted vertical: The pump device is installed vertically on the fuel tank cover plate and is mainly used for quantitative pump systems.

2. Upper horizontal: The pump device is horizontally installed on the fuel tank cover plate and is mainly used for variable pump systems to facilitate flow adjustment.

3. Side mounted type: The disposal device is horizontally installed on a separate basis next to the fuel tank. The side mounted type can be equipped for use. It is mainly used for systems with a fuel tank capacity of more than 250 liters and a motor power of more than 7.5 kilowatts.

Cooling methods can be divided into two types by station:

1. Natural cooling: Cooling by heat exchange between the fuel tank itself and the air, is generally used for systems with a fuel tank capacity of less than 250 liters."

2. Forced cooling: Forced cooling is carried out by using a cooler, which is generally used for systems with a fuel tank capacity of more than 250 liters.

Main technical parameters: Effective oil storage of the fuel tank and motor power

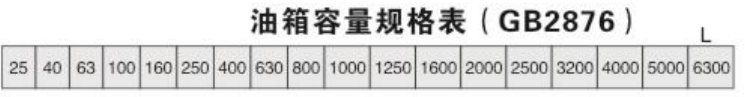

There are 18 specifications for fuel tank capacity. The following table,

According to user requirements and working conditions, the hydraulic station can:

1. Configure integrated blocks by system.

2. Coolers, heaters and accumulators can be set up.

3. Electrical control devices can be set up.

Search

Search