Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

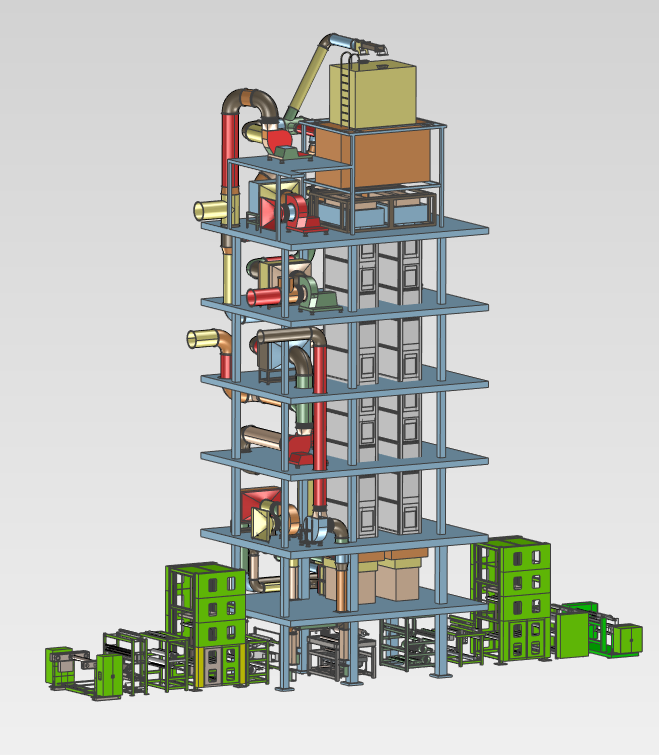

Equipment parameters:

Tonnage: 550 tons

Number of openings: 10 floors

size: 1200mm * 1350mm * 45mm

Heating method: heat conductive oil electric heating

Temperature: Max280℃

Principle of high temperature laminator:

The laminator is a professional production equipment that presses glass, EVA, and backboard (or its substitutes) together through heating and vacuum processes. The current heating methods are divided into two types: electric heating and oil heating.

Introduction to high temperature laminator:

1. A fully automatic pressing system with high temperature, high pressure, high precision and high efficiency.

2. The special hot plate design greatly reduces the unevenness of temperature when heating and cooling. Intelligent temperature control combined with sophisticated processes can achieve the best temperature.

3. The parallelism and flatness of a single hot plate are within ±0.015mm/m; the temperature tolerance is within ±1.5°C.

4. Floating system design and unique technical capabilities are suitable for pressing high-quality products.

5. Floating aerial feeding reduces wear on carrier trays and hot plates.

6. The software is perfectly integrated to avoid human intervention and reduce human error.

7. Reduce production costs and energy-saving design.

![[Used] laser](https://cdn.sumecdtx.com/equipment/20230818/928f9346aceb42e3b60670c380399f59.jpg)

Search

Search