Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

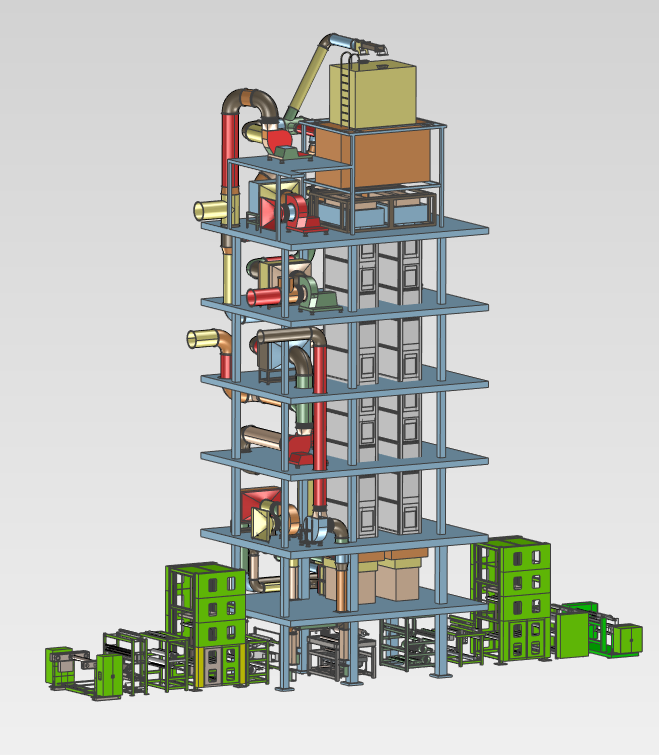

Equipment parameters:

Tonnage: 200 tons

Number of openings: 6 floors

size: 750mm * 750mm * 45mm

Heating method: Electric heating heat transfer oil heater one-to-one method

Temperature: Max280℃

Vacuum hot press is a laminating machine for hot pressing at high temperature. Semi-automatic and fully automatic operation types. It is widely used in fields such as FPCB flexible board and RFPCB rigid-soft composite board for hot pressing under high temperature and high vacuum conditions.

Safety operating procedures for hot press:

1. Preparation for homework

1. Clean up the machine (including glue stains on the light plate) and the workplace;

2. Check the oil bed and oil path for oil leaks;

3. Check whether the oil pump circulation switch is open;

4. If a workpiece of the opposite sex, first check the yin and yang to see if it meets the drawing requirements;

5. After the machine test, preheat the press;

6. Prepare materials and accessories (backing plates, paper sheets, etc.);

2. Operating procedures

1. Set the pressure of the hot press;

2. Put the sample into a hot press, and each time a sheet of one specification is pressed, a first self-inspection must be conducted to see whether it has shifted and whether the glue is firm;

3. At the end of the operation, cut off the power supply and clean up the remaining materials.

![[Used] laser](https://cdn.sumecdtx.com/equipment/20230818/928f9346aceb42e3b60670c380399f59.jpg)

Search

Search