Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

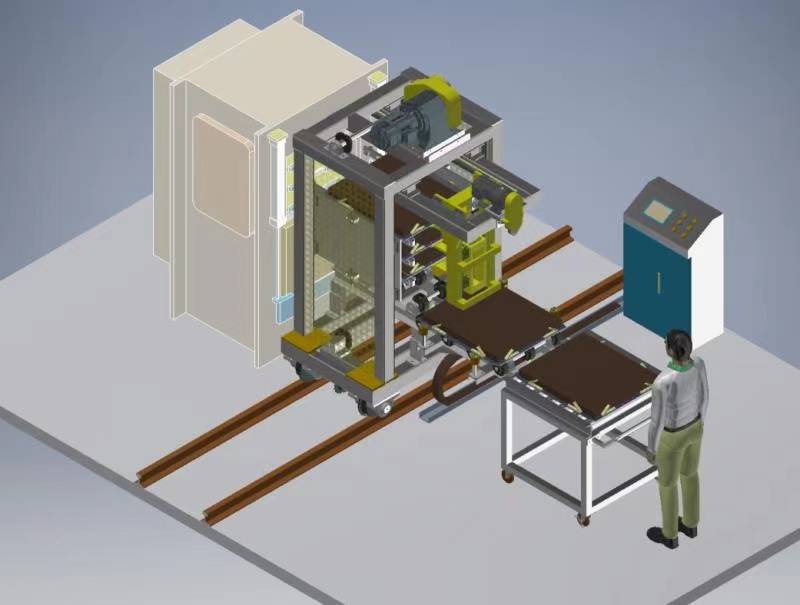

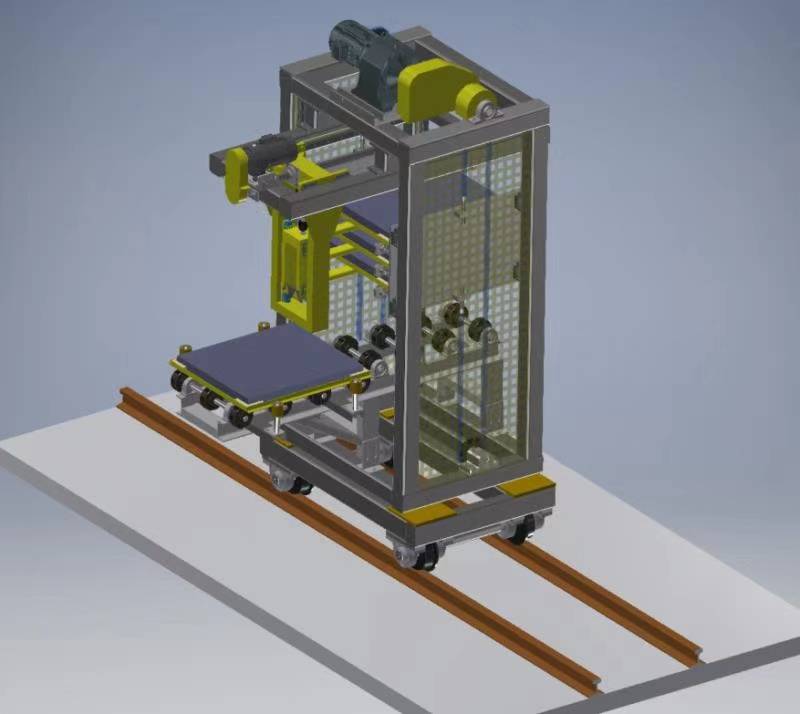

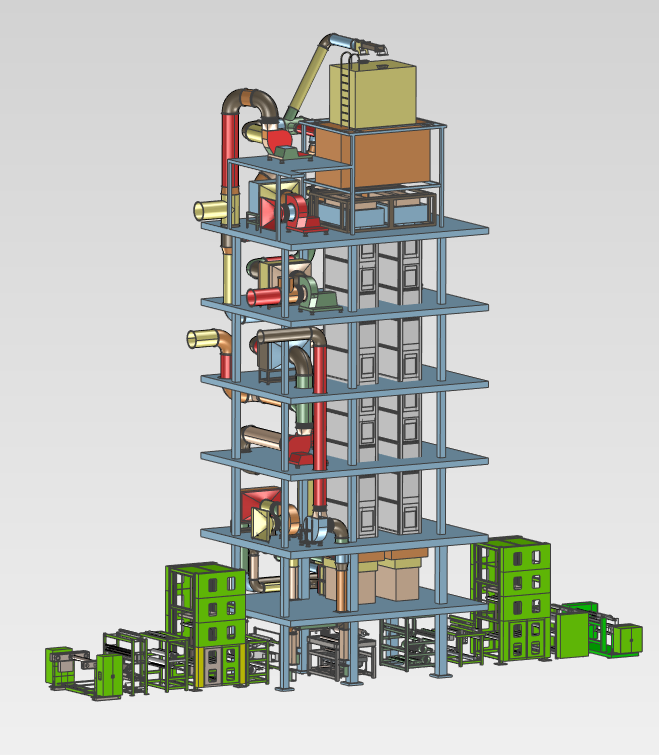

Introduction of vacuum hot press:

1. Vacuum hot press is a laminating machine for hot pressing at high temperature. Semi-automatic and fully automatic operation types. It is widely used in * polymer materials and other fields for hot pressing under high temperature and high vacuum conditions.

2. The composition structure of the vacuum hot press is made of fixed steel materials, supplemented by precise design. The fully welded skeleton can operate under complex conditions of high temperature and high pressure.

3. The furnace body of the vacuum hot press is a vertical furnace shell, with the inner layer being a stainless steel cylinder and the outer layer being carbon steel; the vacuum system is composed of an oil diffusion pump, a Roots pump, equipped with an electromagnetic pressure difference valve, an inflation valve, a bleed valve, a vacuum butterfly valve, and a vacuum pressure gauge. The corrugated tube is composed of pipes, vacuum pipelines and brackets. The hydraulic system adopts electric input method. The hydraulic station is equipped with imported proportional valves, pressure sensors, and displacement display adopts grating ruler. The instrument can be set to automatically adjust the pressure, and voltage stability and pressure maintenance can be achieved. The water cooling system consists of various valves and pipe-related devices, and is equipped with an audio-visual alarm for water interruption, which can automatically cut off the heating source or function. The temperature control system uses thyristors to control the temperature, is equipped with PID function instruments, digital display, and has over-temperature sound and light alarm function. The PLC touch screen can also be automatically controlled and retains historical data to facilitate analysis of the sintering process. The inflation system consists of various pipes and valves, and is equipped with electromagnetic bleed valves and pressure sensors. When the pressure in the furnace is higher than the safe value, it will automatically bleed. There is a needle valve on the inflation pipe to control the amount of inflation.

4. The operation mode of vacuum hot press has manual and automatic control working modes. In manual mode, jog adjustments can be made for mold debugging and pressure testing; in automatic mode, products can be semi-automatically processed.

Safety operating procedures for hot press:

1. Preparation for homework

1. Clean up the machine (including glue stains on the light plate) and the workplace;

2. Check the oil bed and oil path for oil leaks;

3. Check whether the oil pump circulation switch is open;

4. If a workpiece of the opposite sex, first check the yin and yang to see if it meets the drawing requirements;

5. After the machine test, preheat the press;

6. Prepare materials and accessories (backing plates, paper sheets, etc.).

2. Operating procedures

1. Set the pressure of the hot press;

2. Put the sample into a hot press, and each time a sheet of one specification is pressed, a first self-inspection must be conducted to see whether it has shifted and whether the glue is firm;

3. At the end of the operation, cut off the power supply and clean up the remaining materials.

![[Used] laser](https://cdn.sumecdtx.com/equipment/20230818/928f9346aceb42e3b60670c380399f59.jpg)

Search

Search