Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

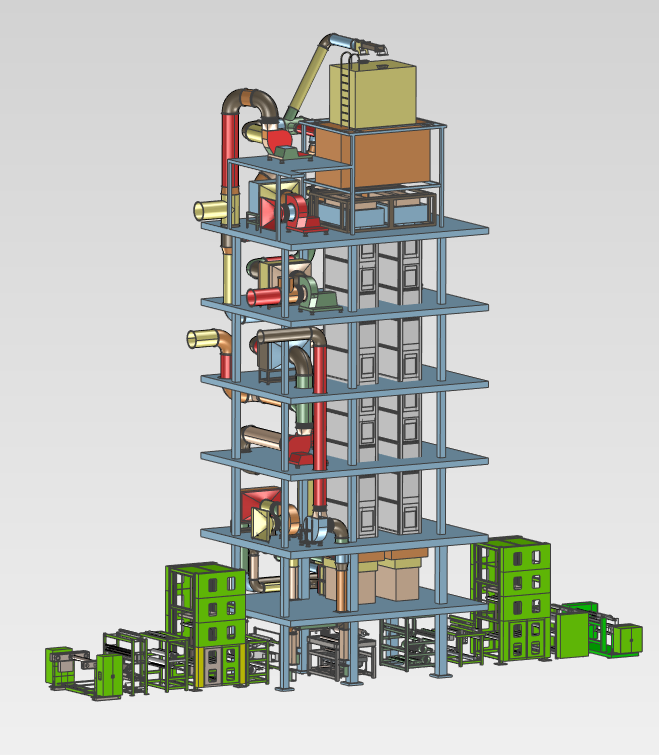

Equipment parameters:

Double width material: 2UP

Tonnage: 1400 tons

Number of openings: 24 floors

size: 1370mm * 2400mm * 60mm

Heating method: boiler + secondary furnace heat transfer oil heating

Temperature: Max280℃

Fully automatic aluminum substrate reflow line coordination (whole factory process)

Introduction of vacuum hot press:

Samples are processed under vacuum hot pressing conditions and processed. A machine that can perform hot pressing treatment, which is of a cyclic operation type. It is widely used in LED,CCL,MCCL aluminum substrates and other materials, cemented carbide, functional ceramics, powder metallurgy and other fields for hot pressing and sintering under high temperature and high vacuum conditions. It can also be inflated under protection and can be formed by hot pressing.

Characteristics of vacuum hot press:

1. Digital temperature control is clear and accurate.

2. Equipped with a digital pressure switch, the pressure range can be preset.

3. When the pressure is started, the hot pressing time is more accurate.

4. Welded joints made of unique materials ensure that the product is subjected to uniform stress.

5. Equipped with vacuum function, alignment is easier.

Safety operating procedures for hot press:

1. Preparation for homework

1. Clean up the machine (including glue stains on the light plate) and the workplace;

2. Check the oil bed and oil path for oil leaks;

3. Check whether the oil pump circulation switch is open;

4. If a workpiece of the opposite sex, first check the yin and yang to see if it meets the drawing requirements;

5. After the machine test, preheat the press;

6. Prepare materials and accessories (backing plates, paper sheets, etc.).

2. Operating procedures

1. Set the pressure of the hot press;

2. Put the sample into a hot press, and each time a sheet of one specification is pressed, a first self-inspection must be conducted to see whether it has shifted and whether the glue is firm;

3. At the end of the operation, cut off the power supply and clean up the remaining materials.

![[Used] laser](https://cdn.sumecdtx.com/equipment/20230818/928f9346aceb42e3b60670c380399f59.jpg)

Search

Search