Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

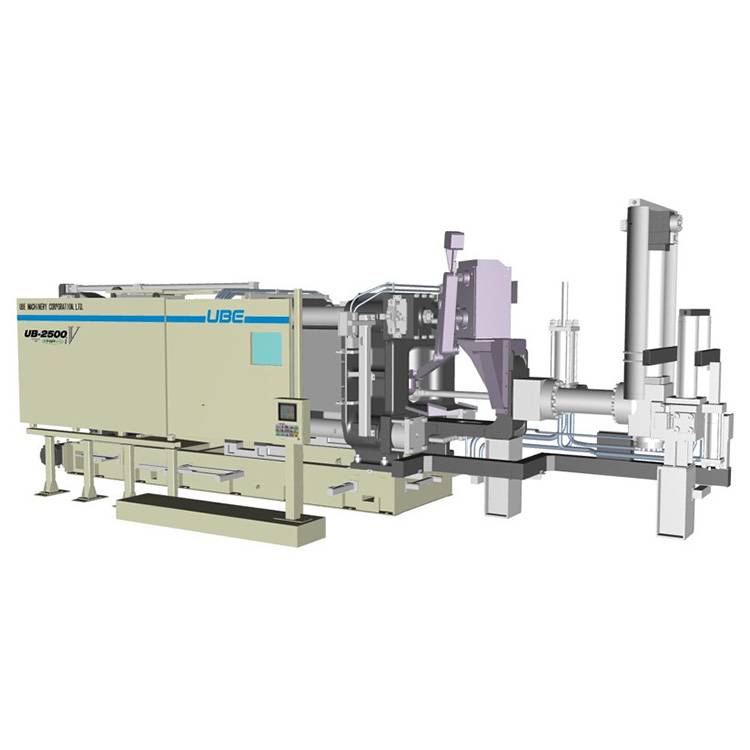

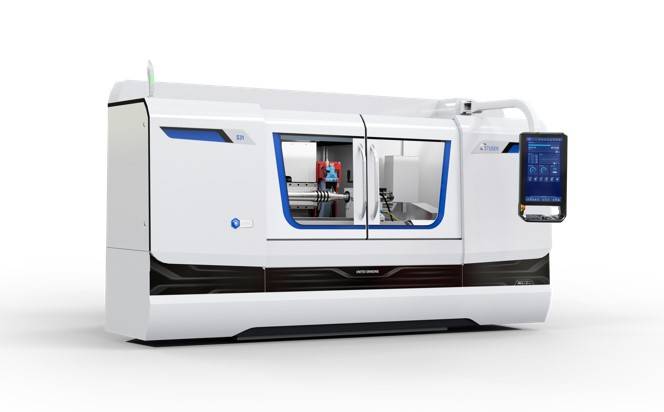

阿瑞斯ARF-T7铝合金铸件热处理线,适用于铝合金减震塔等薄壁件的固溶、时效热处理工艺。根据工件的大小以及重量不同,可以采用单层料框或多层料框(自动堆垛,专利号:2016214624611)以及料架挂件的方式装载工件。淬火采用空气淬火,风量、风向可调,即保证冷却速度,同时保证工件冷却均匀性,减少工件变形。

Roller hearth furnace for T7 heat-treatment of Al-alloy parts is suitable for the solution and aging heat treatment process of aluminum alloy shockabsorber and other structure parts. According to the size and weight of the workpiece, the single-layer material basket or multi-layer basket(automatic stacking, patent No.:201621462461l) and material frame hanging can be used to load the workpiece.Air quenching is adopted for quenching, and the air volume and wind direction can be adjusted,to ensure the cooling speed and the cooling uniformity of the workpiece and to reduce the deformation of the workpiece.

高品质高效自身预热燃烧系统,低能耗,低NOx排放。强对流加热循环和脉冲燃烧控制,升温速度快,固溶/时效温度均匀性:±3℃,避免工件过烧,减少工件的变形。连续生产模式,过程稳定,控温精度高,温度均匀性好。冷却速度快,在2.5分钟以内,工件温度降到200℃以下,淬火转移时间小于10秒。根据工件形状设计合适的料框,确保工件在热处理过程中变形最小。

High efficiency self preheating combustion system with low energy consumption and NOx emission reduced.Strong convection heating cycle and pulse combustion system, fast heating rate, uniformity of solution / aging temperature degree:± 3℃, avoid Over burning of workpiece, reduce deformation of workpiece. Continuous production mode, the process is stable, the temperature control precision is high,and the temperature uniformity is better.The cooling speed is fast.Within 2.5 minutes, the temperature of workpiece drops below200 °℃,and the quenching transfer time is less than 10 seconds. According to the shape of the workpiece, the appropriate material frame is designed to ensure the minimum deformation of the workpiece in the process of heat treatment.Our patented high efficiency jet quenching cooling device has high cooling efficiency.

Search

Search