Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

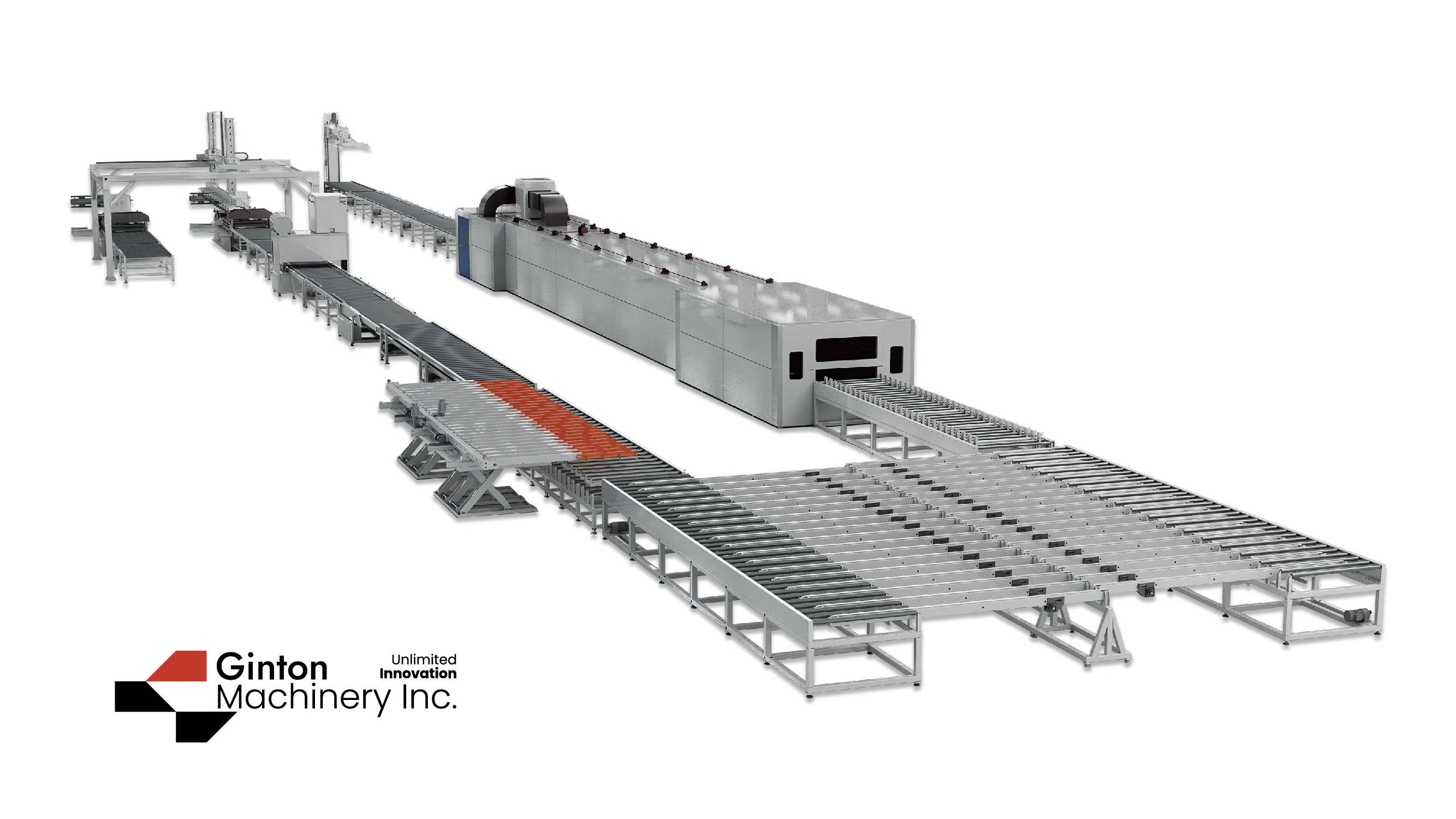

Automatic Filled Can gantry Palletizer machine automatic canning depalletizer

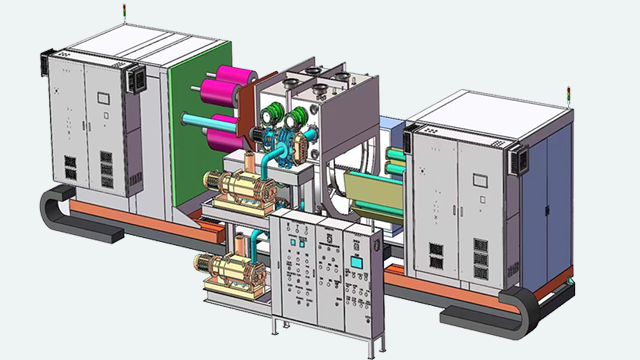

The magnetic depalletizing system is a device that uses a magnetic suction mechanism to perform automated depalletizing operations. It mainly consists of the following parts:

1. Lift mechanism diagram: used to provide lifting function to transport goods from high places to required locations. Lifting mechanisms usually include electric lifts, guide rails, sliders and other components, and the goods can be moved up and down through a control mechanism.

2. Transplanting mechanism: used to move goods from the lifting mechanism to the designated location. The transplanting mechanism usually includes transmission devices, transmission devices and other components, and the translation and placement of goods is achieved through a control mechanism.

3. Magnetic pickup mechanism: It is the core part of the magnetic depalletizing system and is used to suck and manipulate goods. The magnetic suction mechanism is usually composed of electromagnets, magnetic materials, etc., and realizes the suction of goods through electromagnetic principles.

4. Conveyor line: used to move goods from the lifting mechanism to the target location or the next process. Conveyor lines are usually composed of conveyor belts, rollers and other components, and the continuous transportation of goods is achieved through transmission devices.

5. Electrical control: used to control the operation of the entire magnetic depalletizing system and the coordination of each part. Electrical control usually includes components such as sensors, PLC controllers, and touch screens to monitor and operate the system through electrical signals.

Search

Search