Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

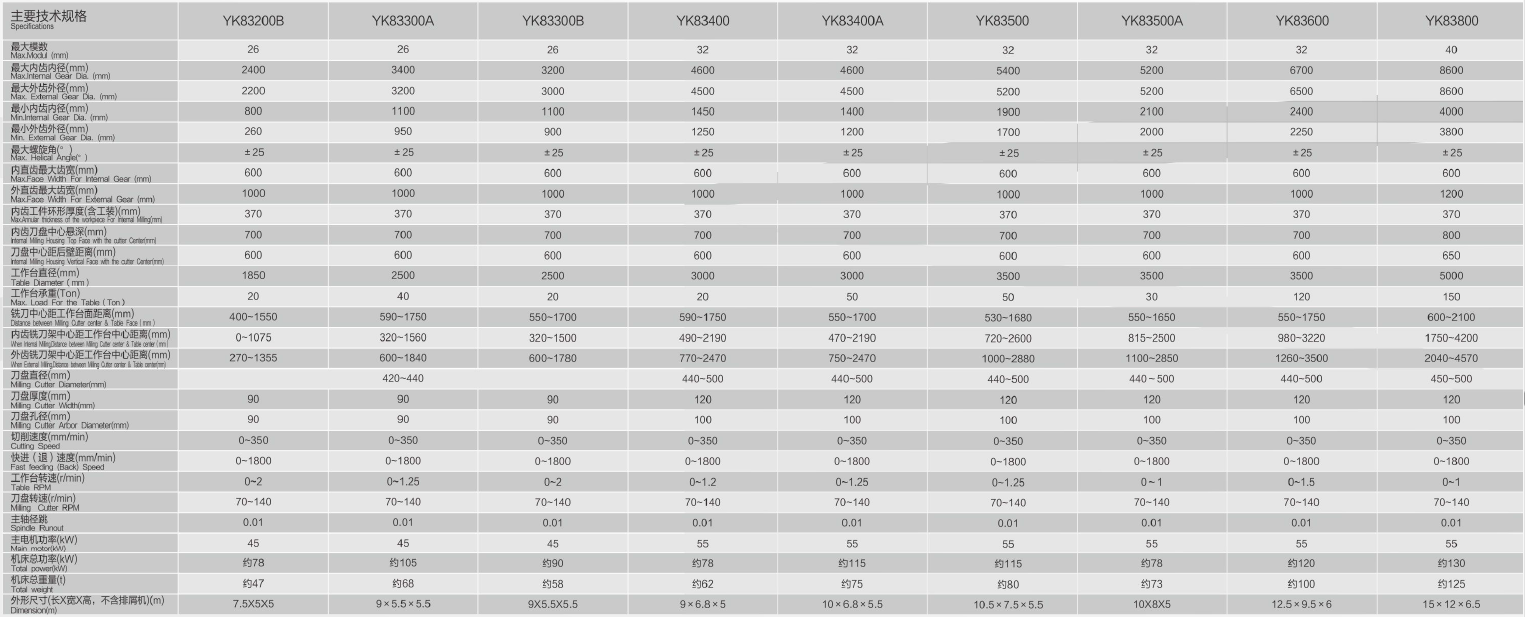

High efficiency gear milling machine is mainly used for high effiency and high precision machining of internal and external spur, helical gears, soft tooth surfaces and medium hard tooth surface gears. It is widely used in rough and finish machining of construction machinery, slewing bearings, wind power slewing bearings, wind power gearbox gears, mining machinery and metallurgical machinery gears. Processing range covers 450mm-8000mm.

Machine tool characteristics

1. The machine is made of high quality cast iron with reasonable layout of bars, good rigidity and strong vibration absorption.

2. Milling head adopts full anti-backlash structure, transfers large cutting power, reduces cutting noise of milling teeth, improves tooth surface finish and prolongs tool life.

3. Single/twin turbines: According to the characteristics of different industries, the high-precision and high-rigidity worktables are equipped with single/twin turbines.

4. The tool holder adopts international advanced structure for axial movement, and adopts right-angle reducer, power loss controller and motor lock to ensure safety.

Search

Search