Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

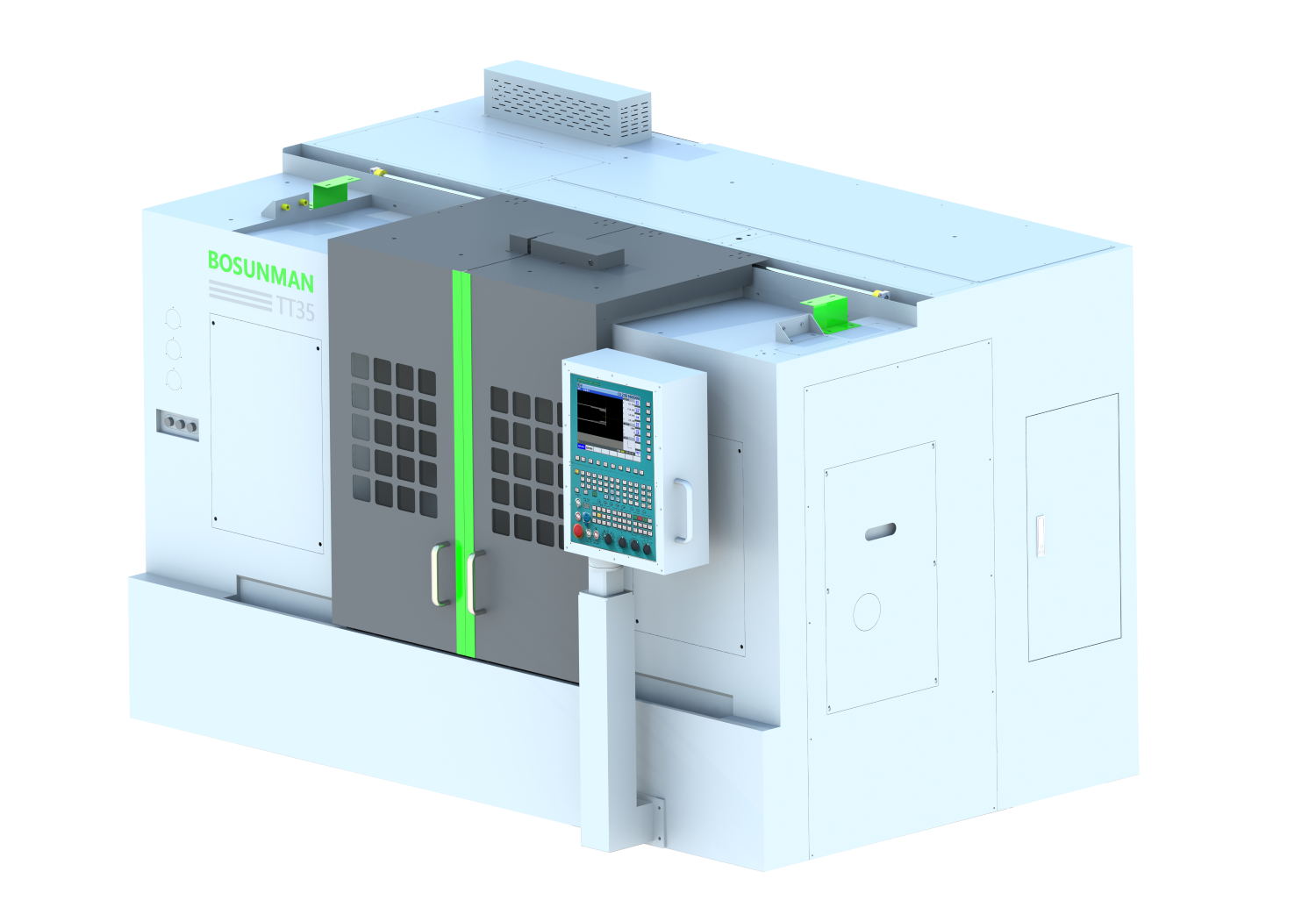

This machine tool is a kind of green and environmentally friendly skiving machine tool with high efficiency, high precision and high automation. It has obvious processing advantages. It is especially suitable for the cutting of small and medium-sized internal and external cylindrical gears in automobile, robot, *, * industry and other industries. It can realize one-time clamping for straight teeth, helical teeth, drum teeth, taper teeth and multi-joint teeth.

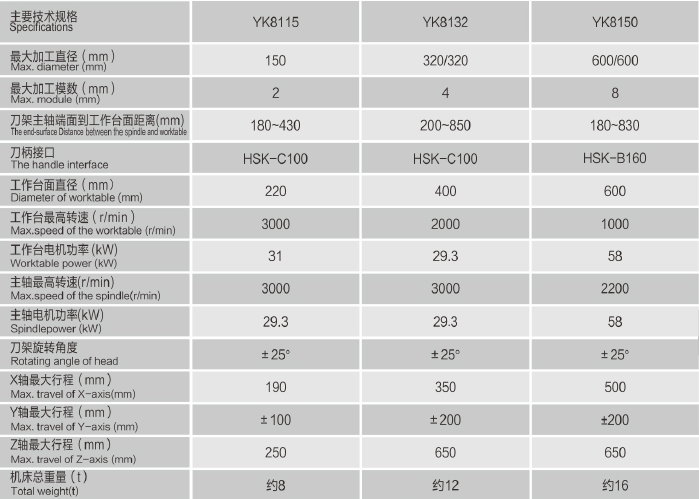

The YK8150 CNC gear skiving machine adopts a new gear processing method—power skiving. Compared with the traditional gear processing machine such as hobbing, shaping, milling and grinding, this machine has the following characteristics : (1)High precision—The machining precision of skiving is higher than that of hobbing, milling and shaping;(2)High efficiency—The cutting speed of the cutting tool spindle and the workpiece spindle is fast, and it can also solve the problem that the small and medium-sized internal gear rings can not be processed by hobbing and milling.(3)Advanced processing methods—The traditional gear machining is cutting in the direction of gear teeth, and the scraping teeth are cutting in both the direction of teeth and the direction of tooth shape, which can solve the problem that the traditional gear machining method can not process the internal non-through gear and gear without cutting groove.(4)Greener and more environmentally friendly—High-speed dry cutting can be used to ensure high efficiency, high quality, high tool durability and high reliability of the cutting process without using cutting fluid, higher resource utilization rate and more obvious comprehensive benefits;(5)Higher flexibility—can process helical gears of various angles and tooth profile and tooth direction modification.(6)High rigidity structure design—Through the optimization design of each component, key structure and numerical control axis parameters, the machine tool has high dynamic and static rigidity.(7)Tool spindle and workpiece spindle adopt high power motorized spindle direct drive technology to ensure high rotary precision and following precision. (8)High motion accuracy:The linear motion axis adopts the structure of steel insert guide rail and rolling block preloading to ensure that there is no gap in the movement of the machine tool.(9)Powerful processing software, stable and reliable control system. It has the functions of automatic tool centering, automatic tool protection, man-machine interface, multi-axis synchronization and so on.

Search

Search