Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

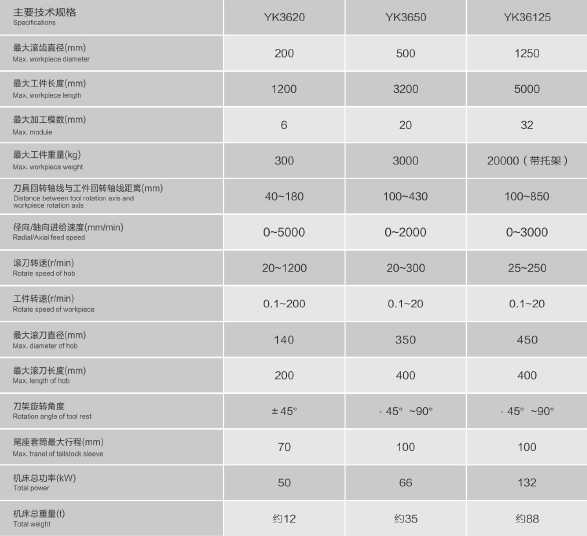

YK36 series is used to process all kinds of straight/helical gears, splines, coupling gears, as well as taper splines and step gears; It is used in the processing of long axis parts in automobile, construction machinery and other fields. Special software can be selected to process drum teeth, herringbone teeth, worm gear and other special workpieces; Standard high-speed dry cutting, optional wet cutting processing. And optional center frame, auxiliary support mechanism and so on.

Machine tool characteristics:

1. Rich flexible functions. In addition to processing a variety of straight/helical gears, splines, coupling gears, as well as taper splines and step gears, we can also select a variety of special software packages to process drum teeth, herringbone teeth, worm gear and other parts.

2. Efficient dry cutting. The machine can carry out high-speed dry cutting processing, and the linear speed of the typical workpiece with the dry cutting tool can be more than 150m/min, which greatly improves the processing efficiency. In addition, it is also optional to install ordinary tools for oil cold wet cutting.

3. Tool spindle transmission belt anti-backlash structure. Driven by high-power spindle motor, transmission gear box with differential tooth clearance mechanism, improve cutting rigidity and transmission smoothness, low noise, effectively increase the durability of the tool.

4. Workpiece spindle transmission belt anti-backlash structure. Transmission box with closed gear anti-backlash structure, can automatically follow the transmission situation always eliminate the transmission pair clearance, and through the control system for error compensation, to ensure a high precision of following rotation.

5. Complete protection functions. The machine comes standard with power off rollback and one-click tool retreat function. If the power failure occurs during the machining process, the radial feed shaft can automatically and quickly backtrack, and the tool shaft and the workpiece shaft maintain an electronic gearbox coupling relationship until the hob automatically exits the cutting area to prevent tool damage and protect the machine tool. In addition, if there is an abnormal situation in the processing process, it can be manually operated under the condition of maintaining the coupling relationship of the electronic gear box.

6. High degree of automation, easy to operate.

Machine tool with automatic broach function, easy to change the tool;

The rotation of the tool holder is driven by the precise worm gear pair, which can automatically adjust the Angle accurately and improve the machining accuracy.

7.Strong structural rigidity. The main parts of the machine tool, such as the bed, the column, the hob frame, the headbox and other boxes are made of high-quality cast iron, and the strength check calculation and structural optimization analysis and design are carried out. The structure is reasonable, the rigidity is strong, and the noise and vibration are small.

Search

Search