Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

Introduction of Rod mills:

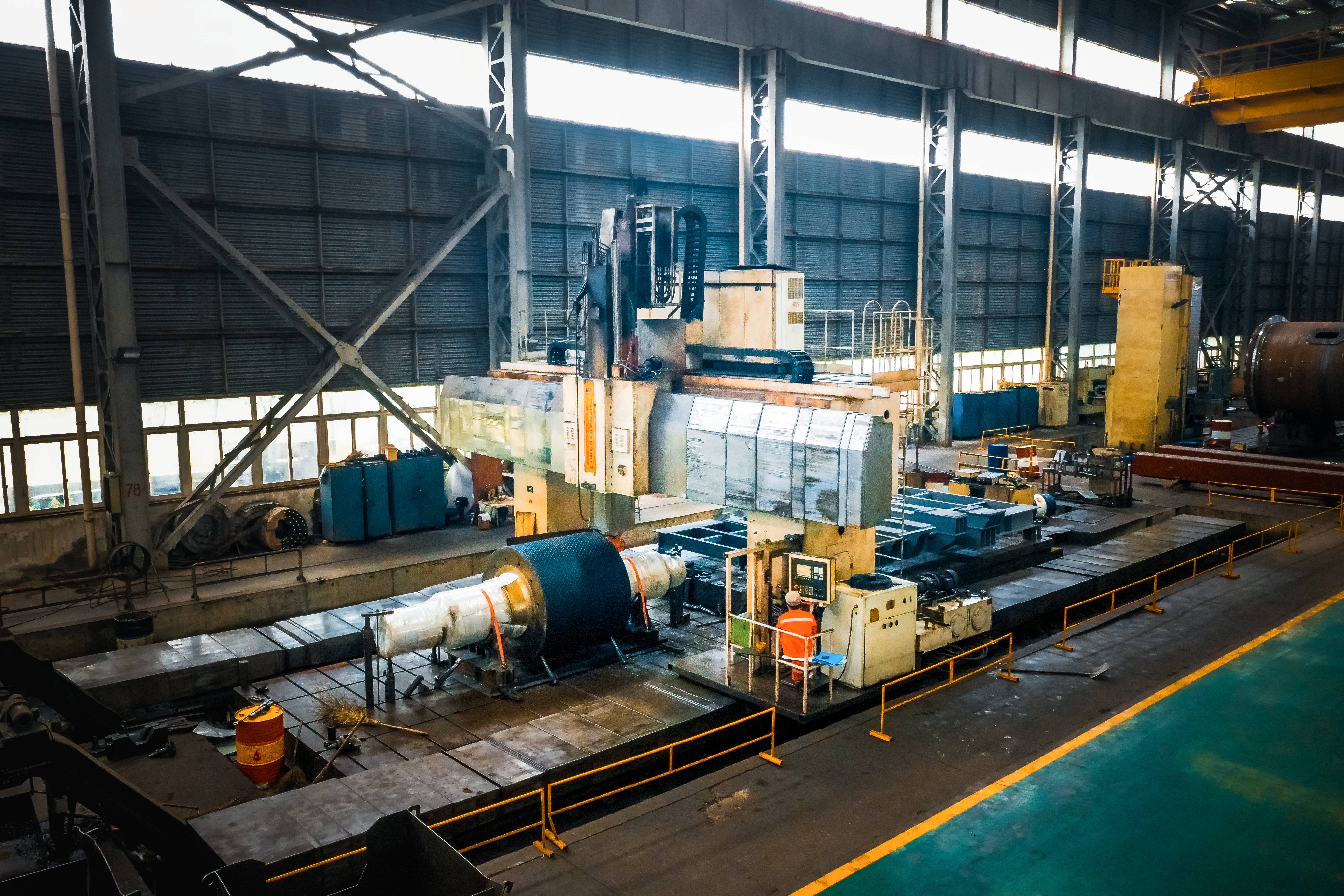

Rod mills are used for rough grinding operations. A certain number of steel rods are loaded into the cylinder as the grinding medium for dry or wet grinding of various ores and other grindable materials. Rod mill is suitable for grinding various ores and other materials. It can be divided into dry and wet grinding methods. There are two discharge modes: central discharge and peripheral discharge.

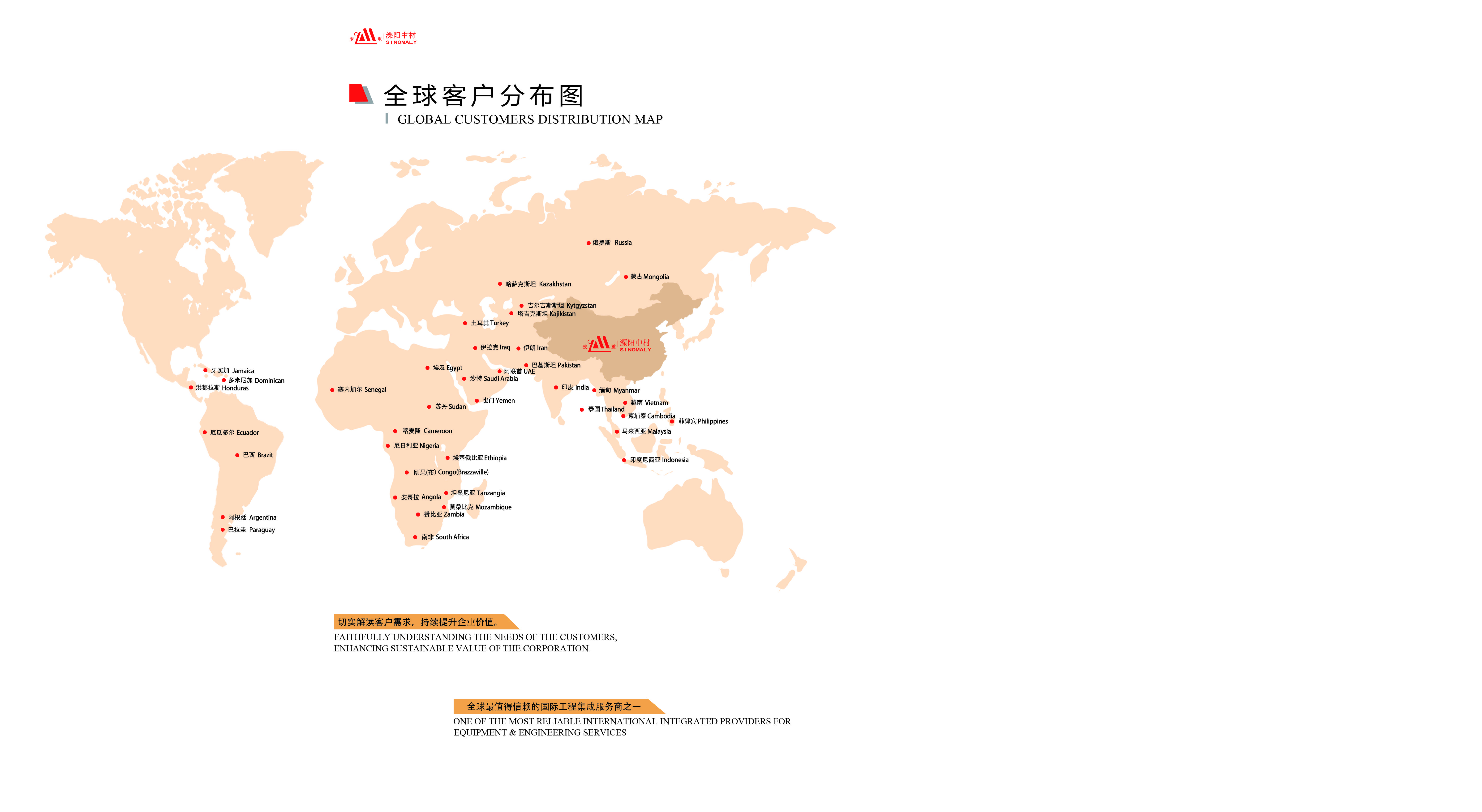

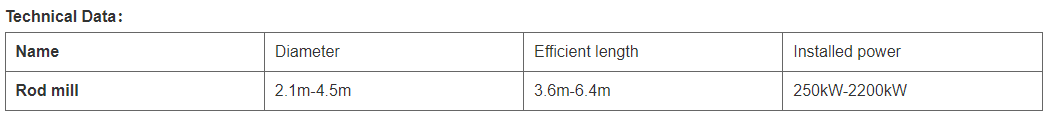

Sinoma Liyang has rich experience in rod mill manufacturing. With complete specifications and wide applications, rod mills can well meet the needs of various mineral processing. The diameter of the rod mill of Sinoma Liyang ranges from 2.1m to 4.5m, and the maximum power is up to 2200KW. Our product R & D team is constantly improving the design of rod mill and optimizing the scheme according to the specific needs of customers, so as to provide more reliable, safe and efficient equipment.

Working Principle:

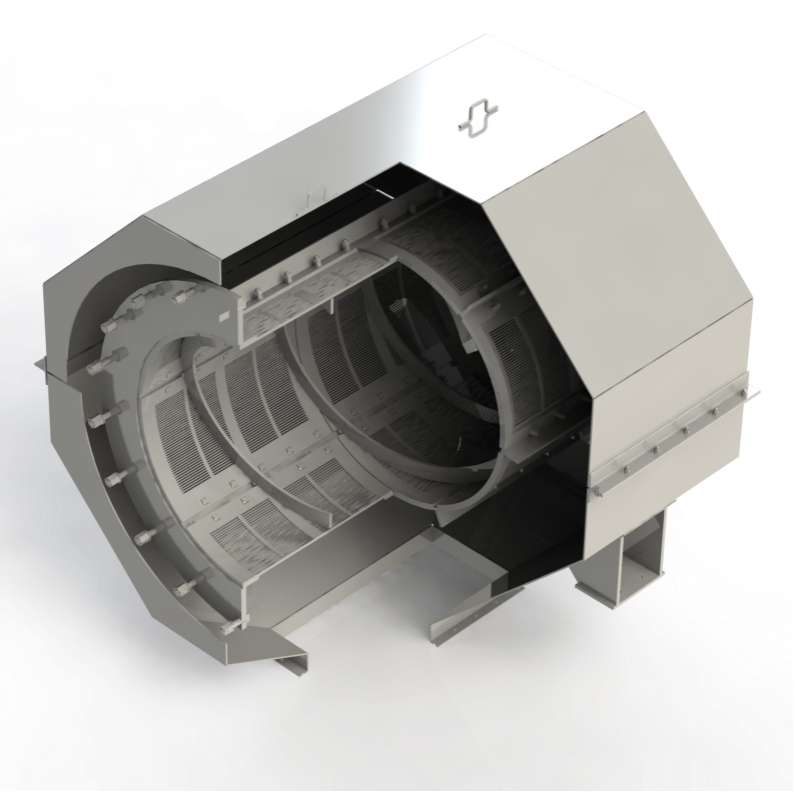

The material enters the cylinder from the center of the feed end cover through the feed part. The motor drives the rotating part equipped with grinding medium (steel rod) and materials to rotate through the transmission device.

A certain grinding medium (steel rod) and materials are installed in the cylinder. Under the action of centrifugal force and friction, the grinding medium and materials are lifted to a certain height with the rotation of the cylinder and fall in a falling state.

The materials in the cylinder are crushed by the impact of the steel bars and the additional crushing and grinding stripping between the steel bars and between the steel bars and the cylinder liner, fully expose the fresh surface and get fully mixed. Finally, the ground qualified materials overflow freely through the center of the discharge end cover or discharge along the ore discharge port around the cylinder to complete the grinding process.

Main design features:

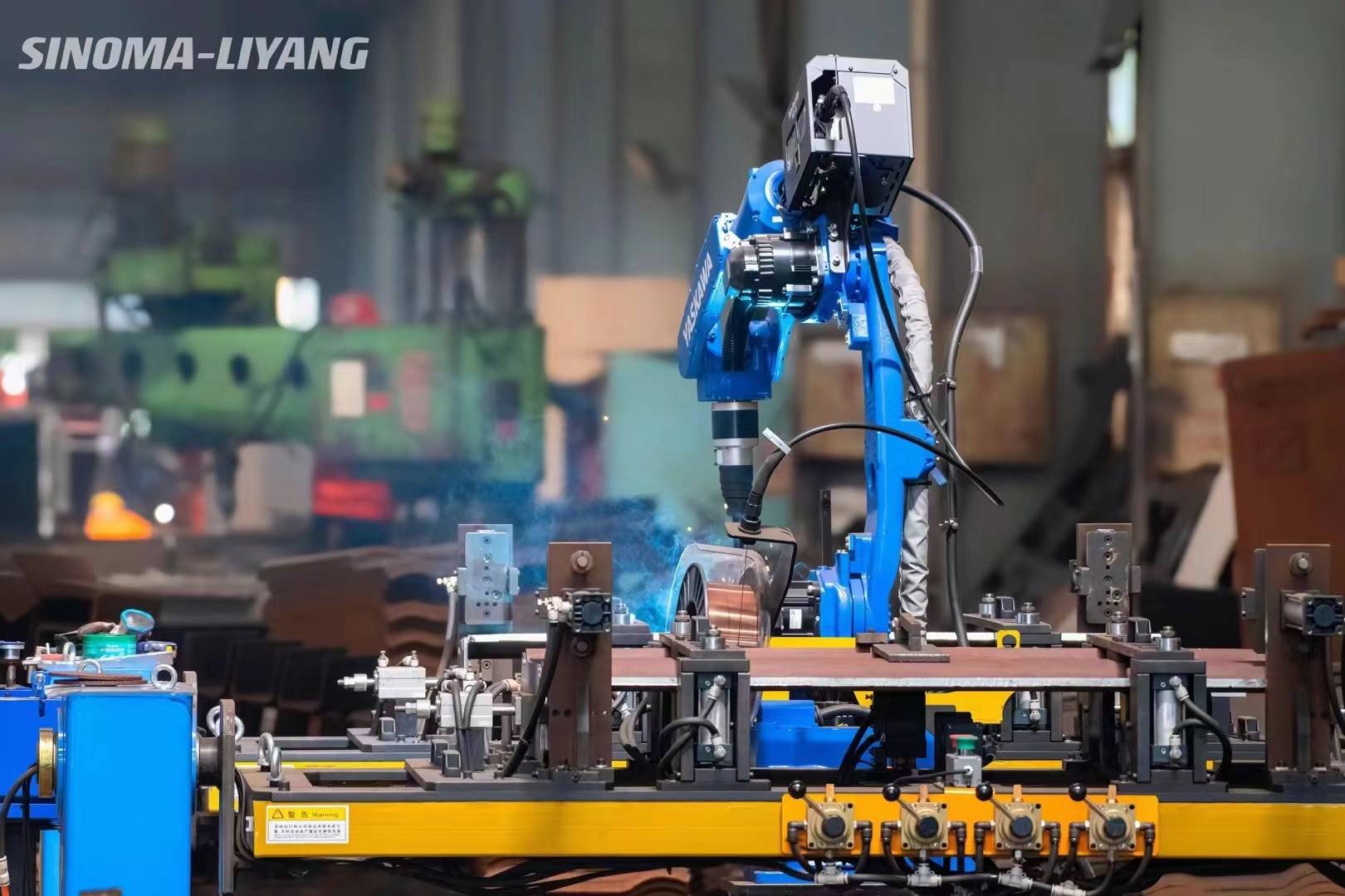

High quality cast end cover and solid welded cylinder greatly prolong the service life of the equipment.

The design of rod mill is supported by a complete set of analysis reports, including finite element analysis of rotating body, finite element analysis of oil film of main bearing, AGMA calculation of transmission gear, torque analysis of transmission system and EDEM discrete element analysis of lining plate.

The equipment has a more efficient and stable full hydrostatic lubrication system.

The equipment has a high degree of automation. It is equipped with PLC control system and one key start, which can monitor the operation status of the equipment in real time.

Main advantages:

After careful design, Sinoma Liyang rod mill can stably provide higher output, safe, reliable, high quality and high efficiency. Choose Liyang rod mill can achieve higher output at lower cost.

Liyang Sinoma semi rod mill has complete specifications and is widely used. We provide rod mills with diameters ranging from 2.1m to 4.5m and maximum power up to 2200KW. You can easily find the specifications you need.

We also provide comprehensive customer service, including life-cycle solutions such as new equipment installation and commissioning guidance, equipment optimization and provision of spare parts.

Product Features:

What you need is a flexible, durable, cost-effective rod mill tailored to your specific needs.

Therefore, we offer a complete range of products with diameters from 2.4m to 4.5m, and provide a variety of design configuration options to suit your needs:

Selection of various application sites: Mining / sand making / coal water slurry / steel slag

Selection of various transmission forms: asynchronous / synchronous, edge transmission / center transmission

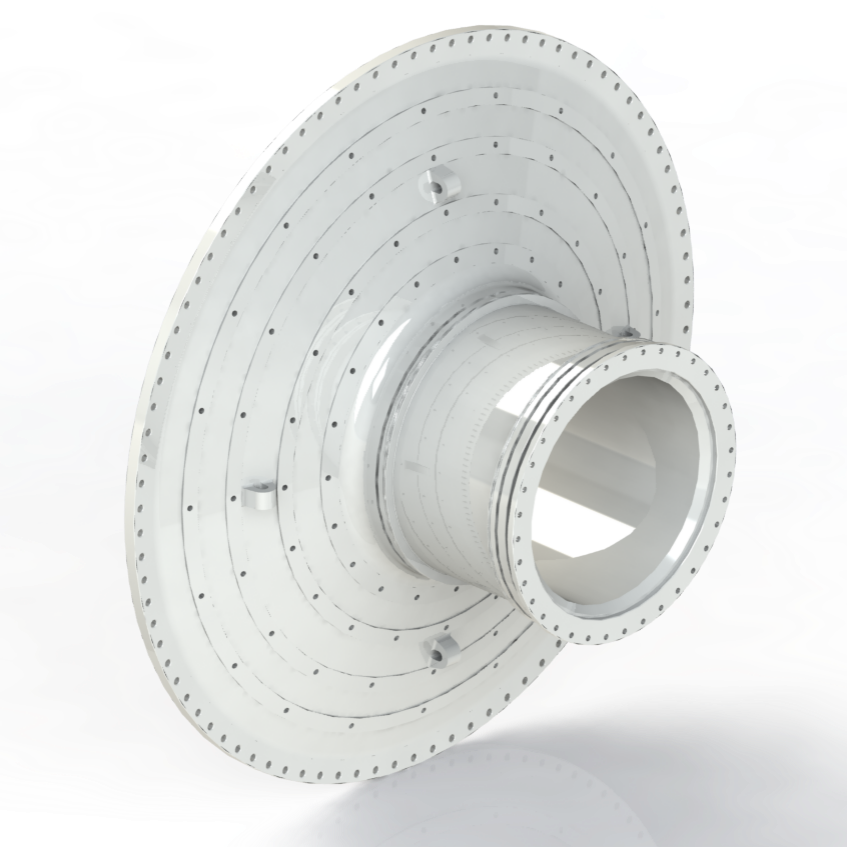

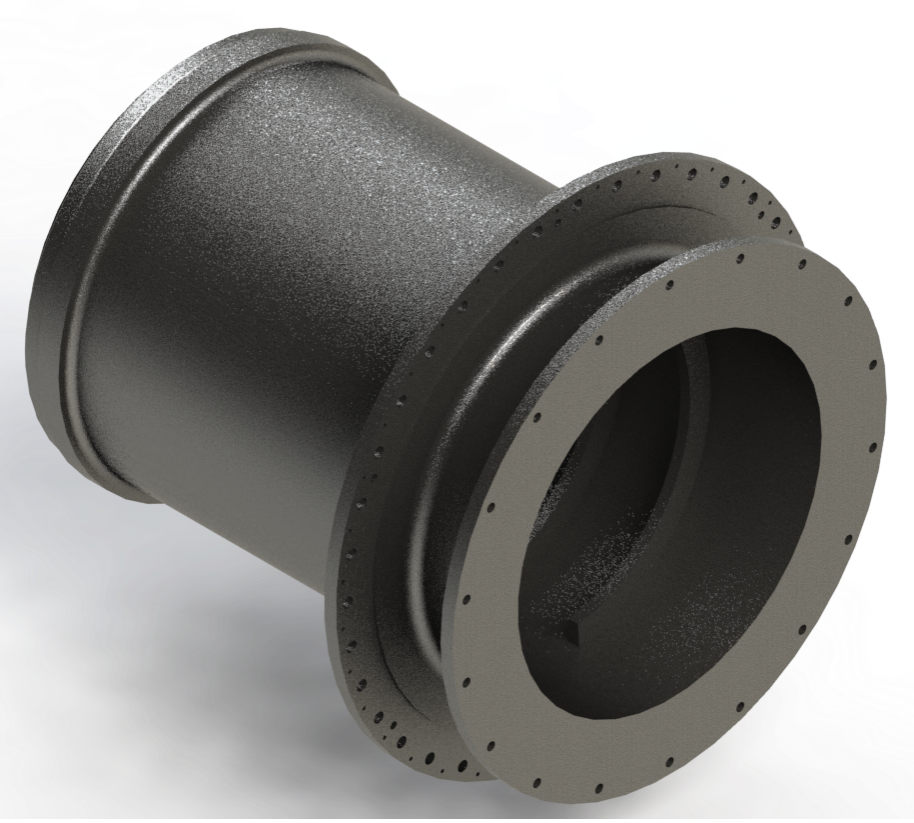

Grinding mill head

Material: cast steel

Design standard: Sinomaly FEA

Type: integral with the trunnion

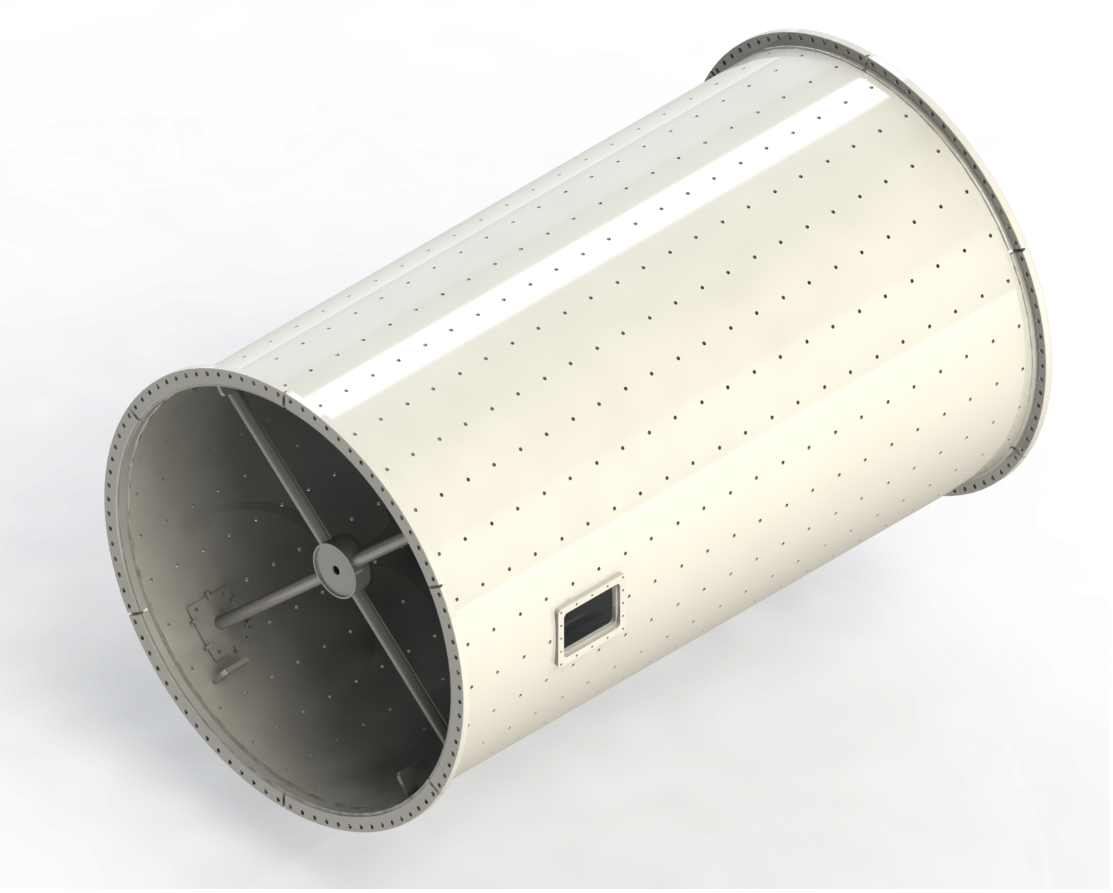

Grinding mill shell:

Material: fabricated steel (welded)

Design standard: Sinomaly FEA

Sections: integral

Segments: one

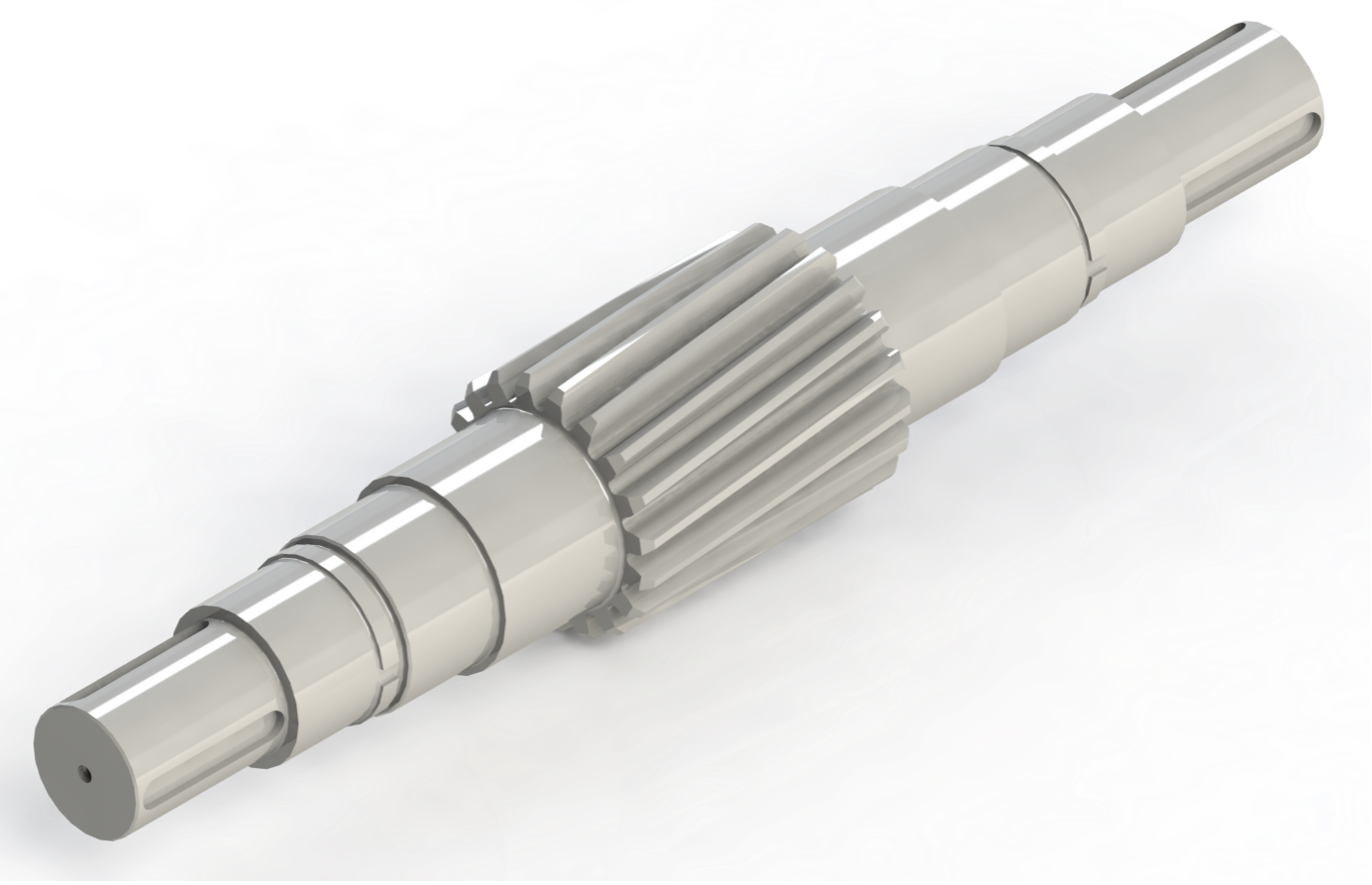

Gears and pinions

Material: cast steel, forged steel

Design standard: AGMA 6014 for open gearing

Gears segments: two-piece

Pinions segments: integral with the shaft/split with the shaft

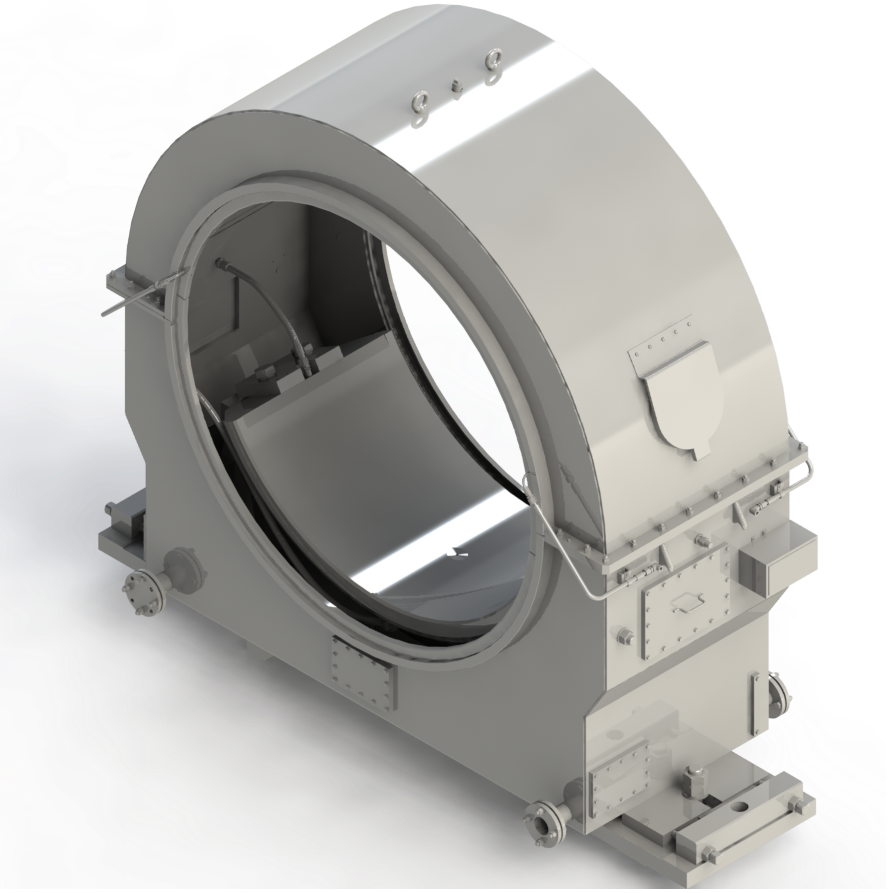

Grinding mill main bearings:

Material: fabricated steel (welded)

Type: rolling or sliding, hydrostatic or hydrodynamic, fixed or floating

Design standard: Sinomaly FEA

Sliding bearings material: babbitt

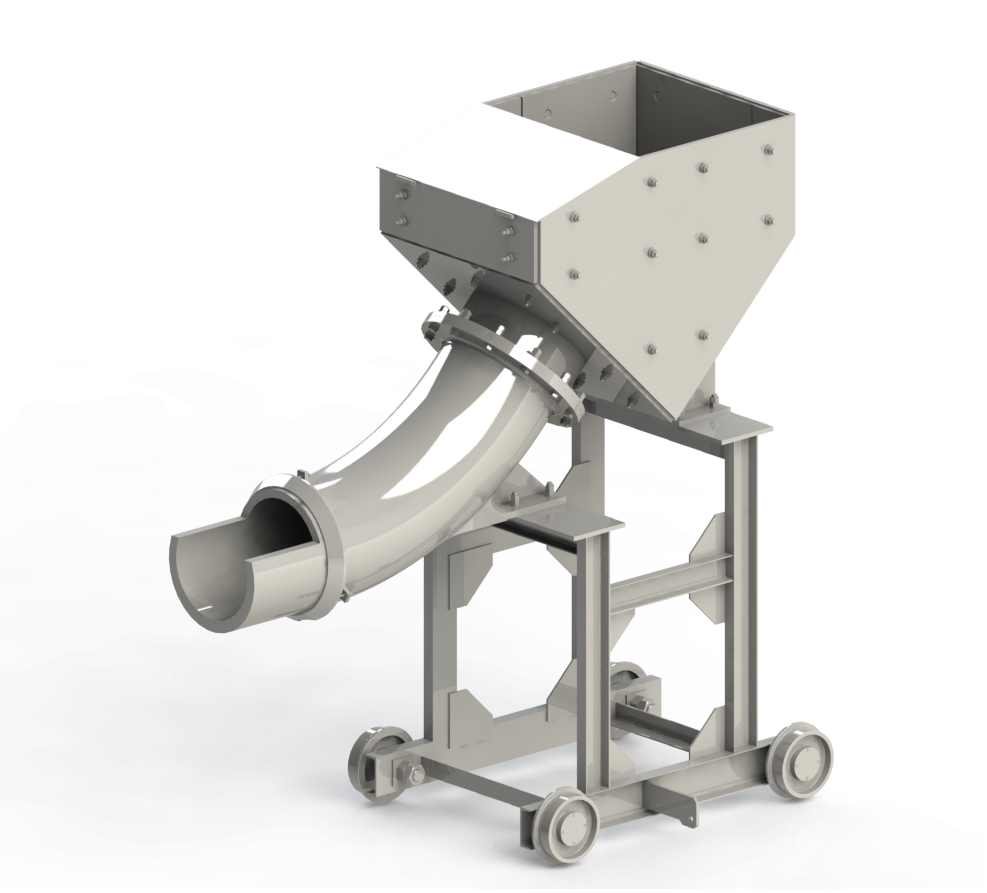

Grinding mill trunnion liners:

Material: cast iron, cast steel

Type: feed or discharge

The movable feeding chute structure is more convenient and durable.

Reliable feed sealing to solve the problem of material leakage at the feed inlet.

Provide discharge cylinder screen.

Search

Search