Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

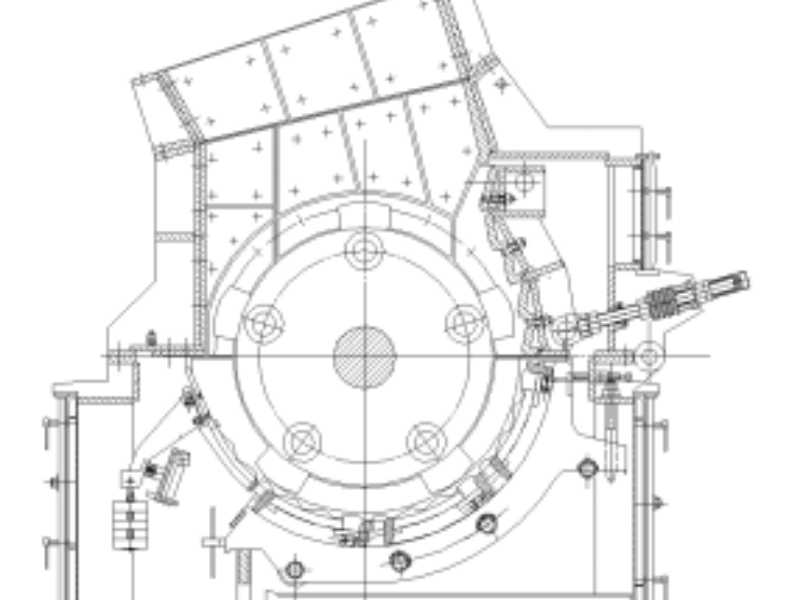

Hammer crusher brief:

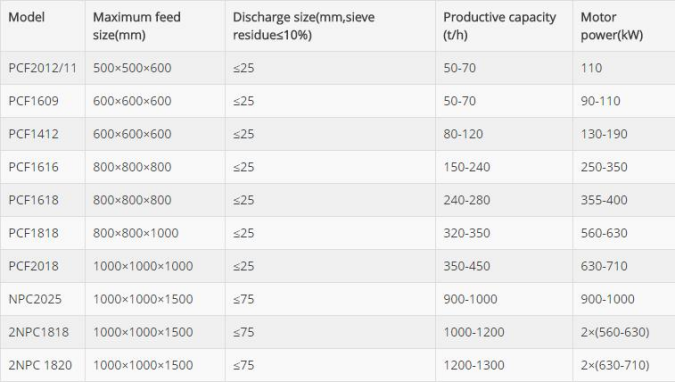

Hammer crushers are primarily used for breaking materials with a compression strength that is less than 200MPa, such as limestone, gypsum, coal, marlstone and sandy shale in cement industries. The hammer crusher can crush the raw ore into small particles of 25mm in a single process, which simplifies the process when compared to traditional multi-stage crushing, thus saving customer investment costs. The hammer crushing equipment can also be added to a complete production line.

Hammer crusher working principle:

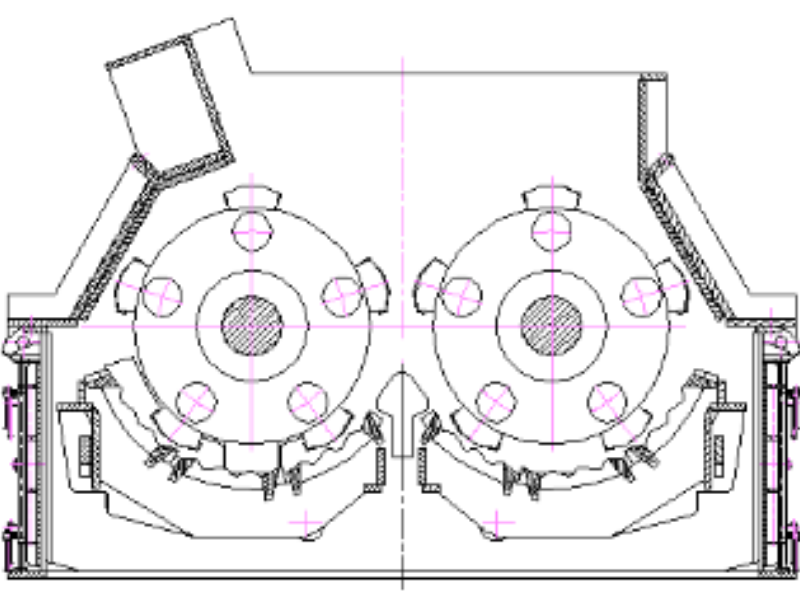

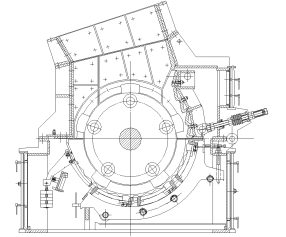

The hammer crusher is divided into single rotor (single-axis) and double rotor (double-axis). The single rotor can be divided into irreversible and reversible two kinds. It is divided into a single row and multi-row. The hammer crusher is impacting the material using a high-speed rotary hammer. The process is as follows: The material enters the machine, immediately under the impact of the high-speed rotary hammer. The pulverized material is obtained from the hammer head, and it is subjected to secondary pulverization at a high-speed liner on the inner wall of the casing. Thereafter, the material smaller than the slit slit, is discharged from the slit, and the material having a large amount of block is bounced back into the track of the hammer, and will be pulverized by the continued impact of the hammer head. Further, the granular material falling on the liner and the grate is again subjected to milling and grinding of the hammer, and the material is in the process of pulverization, and there is also a shock between the materials.

Hammer crusher characteristics:

1. If there are large sized materials that cannot be crushed by the hammer in the first round, the belt pulley mounted on the shaft end will return to the rotor disc in order to ensure a stable rotor operation.

2. Due to its large feeding size design, a variety of minerals can be fed into crusher body.

3. The materials can be crushed once by hammer crusher, and then transferred to the grinding process.

4. The hammer is designed with an entire rotation function, so the material impact on the rotor is significantly decreased.

5. The crushing chamber is adjustable, thus reducing abrasion on wearing components.

6. The rotor of this hammer crusher features a great inertia and high rotating speed, and the linear velocity of the hammer reaches 30~35m/s.

Search

Search