Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

Wobbler Feeder Profile:

Large-scale bulk crushing system often faces a difficult dilemma when dealing with the complex working conditions of mixed soft and hard, viscous and fine materials. The wobbler feeder has the function of pre-screening, which can be set between the apron feeder and the crusher. Through the fluctuation of the triangular arc roller, the sticky wet and fine materials can be screened out in advance, and the large materials can be sent to the crusher, so as to solve the problem smoothly.

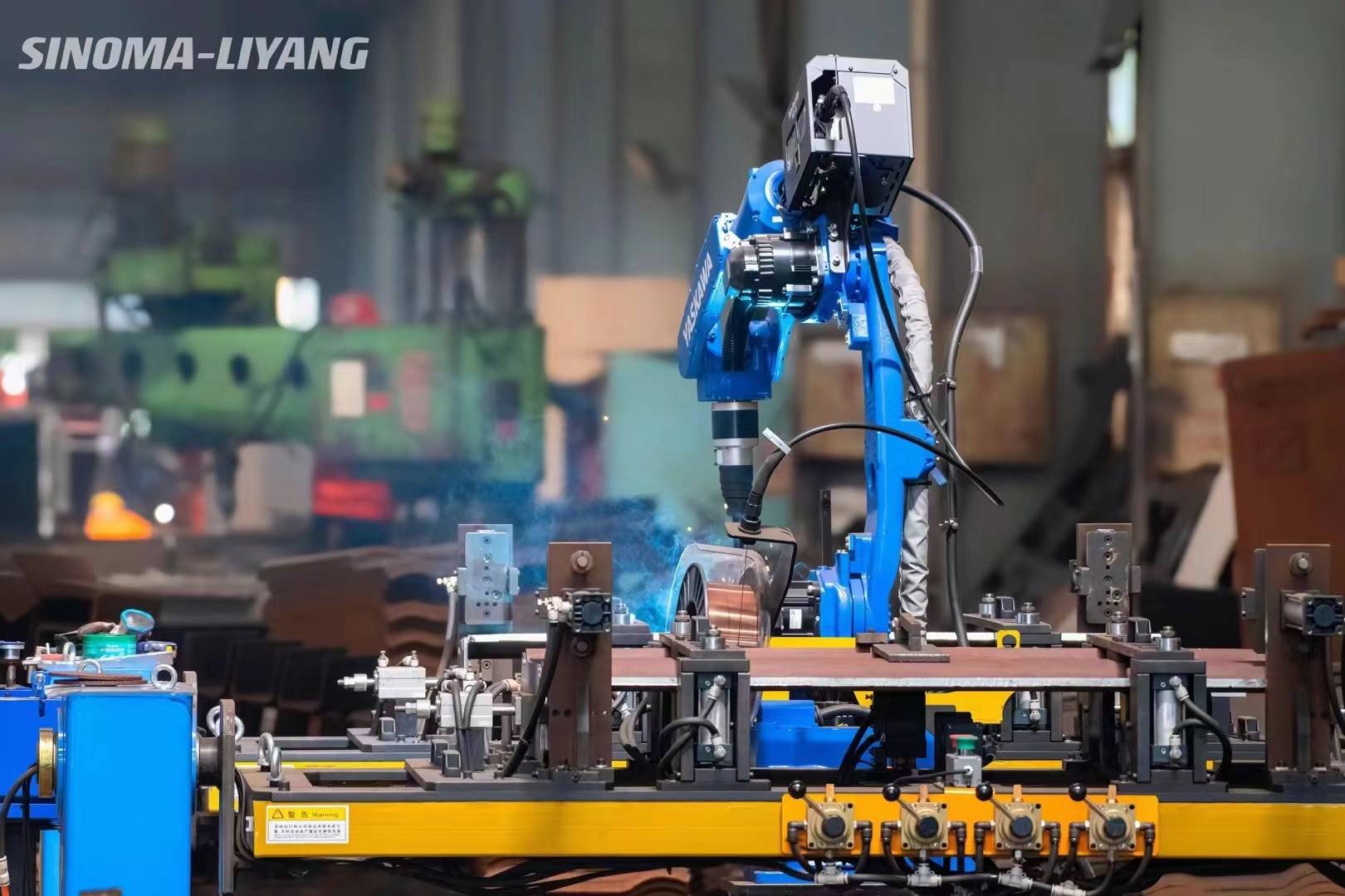

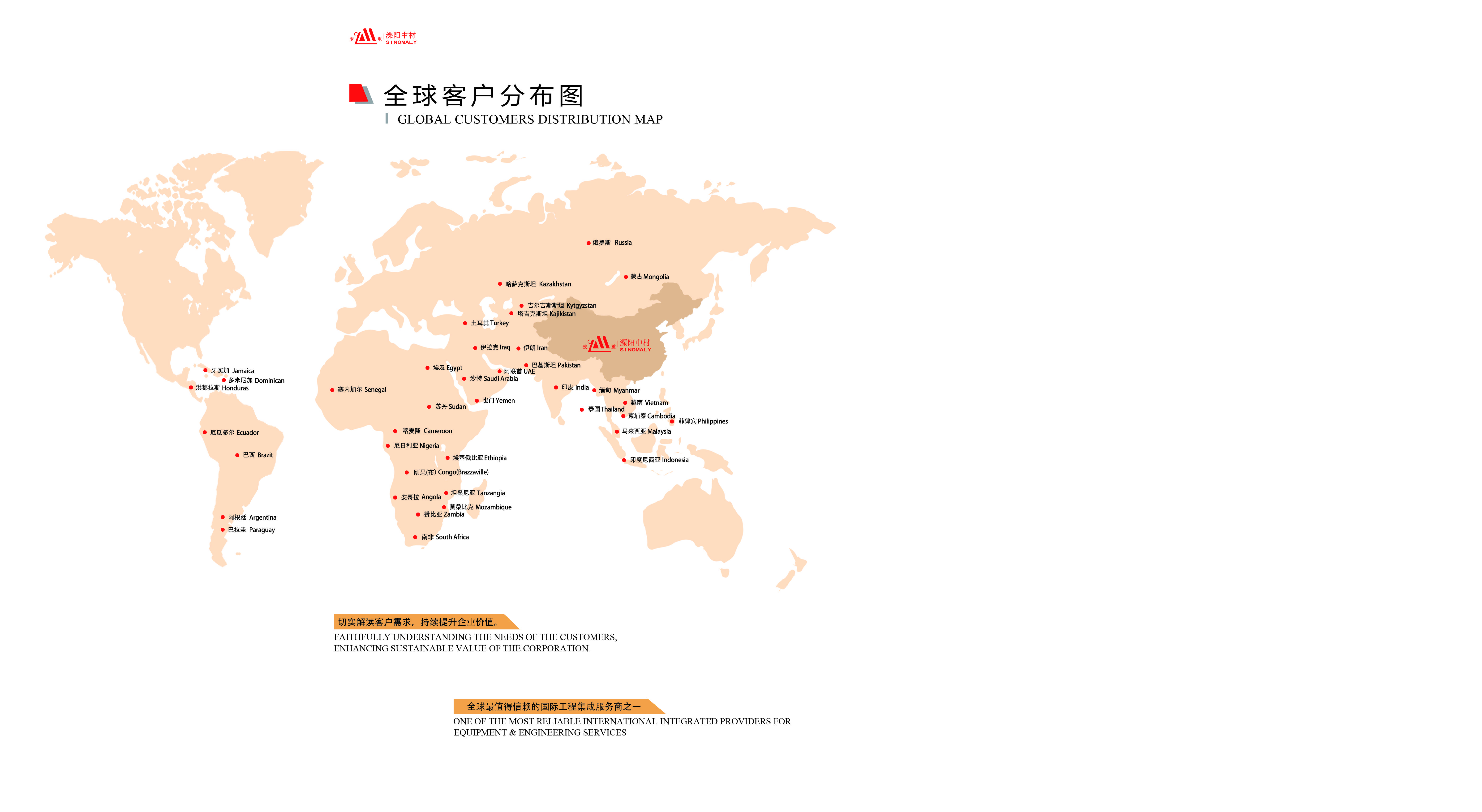

As the key equipment of the crushing system, our wobbler feeder has been successfully applied hundreds of sets in the new and reformed bulk material treatment projects all over the world. It is one of the fist products of SINOMALY.The new crushing process meets the needs of increasing output, reducing ton power consumption, prolonging the life of vulnerable parts, and achieving the purpose of saving energy and reducing consumption.

Structure & principle of wobbler feeder:

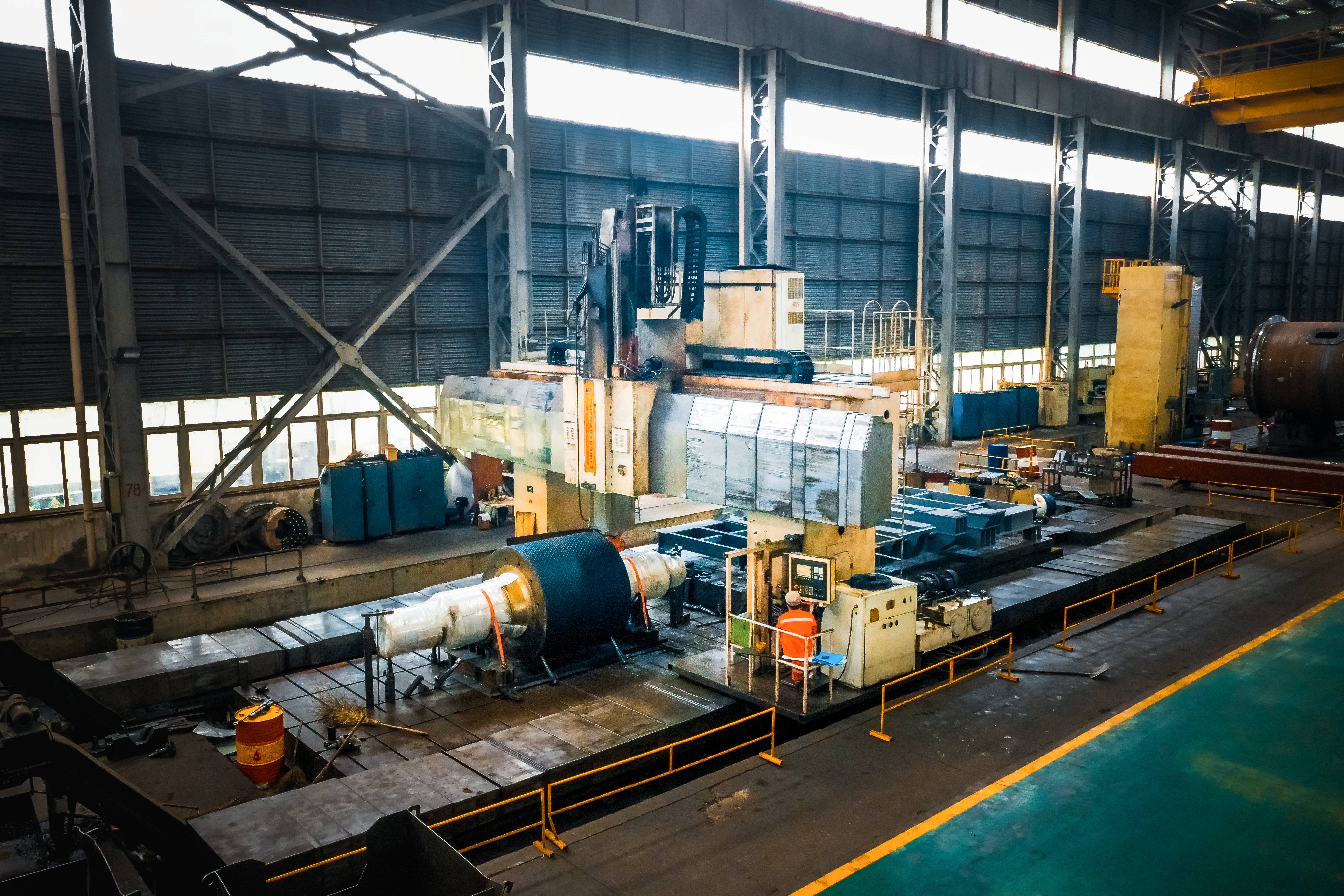

The wobbler feeder is a kind of multi-roller conveying machinery, the whole machine is divided into steel hopper, feeding section and screen section. During the operation of the wobbler feeder, each roller rotates in the same direction, thus supporting the ore on it from one end to the other end. Because each roller has convex edges, the gap between adjacent rollers can cause the small debris to leak out.

Wobbler feeder is mainly composed of feeding roller, screening roller, feeding roller drive device, screening roller drive device, shell, feeding roller drive sprocket group, screening roller drive sprocket group, etc.

(1) feeding roller and screening roller: feeding roller and screening roller have similar structure, only the shape of the roll sleeve is different, the former is cylindrical, the latter is oval or triangular. It is mainly composed of a shaft, a roll sleeve, a clamp on the end face of the roll sleeve, a bearing and a sprocket. The bearing is installed in the bearing box on both sides of the feeder shell.

(2) Shell: The shell is welded into several pieces by steel plate and welded into a box structure by tailor-welding. The upper part of the feeding section is opened so as to be connected with the receiving hopper. The above part of the screen section roller is provided with a closed guide chute, and the top of the guide chute is provided with a manhole for easy access to the machine during maintenance. The parts of the shell where the ore is piled up are inlaid with lining plates.

(3) Driving device: the driving part adopts three-ring reducer to decelerate, divided into two configuration modes of right drive and left drive, with the ore propulsion direction as the front, the driving device is called right drive on the right side, and left drive on the left.

Features of Wobbler Feeder:

(1) After screening out the fine materials and soil that have met the requirements in the raw materials, the production capacity of the crushing system is improved, the wear of the crusher is reduced, and the work is more reliable.

(2) Feeding quantity can be adjusted automatically according to the load of the crusher, giving full play to the working material rate of the crusher.

(3) The wobbler feeder is especially suitable for the screening of large blocks of materials. Equipped with a mud shaving device under the screening roll, which is also competent for wet materials.

(4)The wobbler feeder is easy to install and maintain.

Roller structure of wobbler feeder:

Search

Search