Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

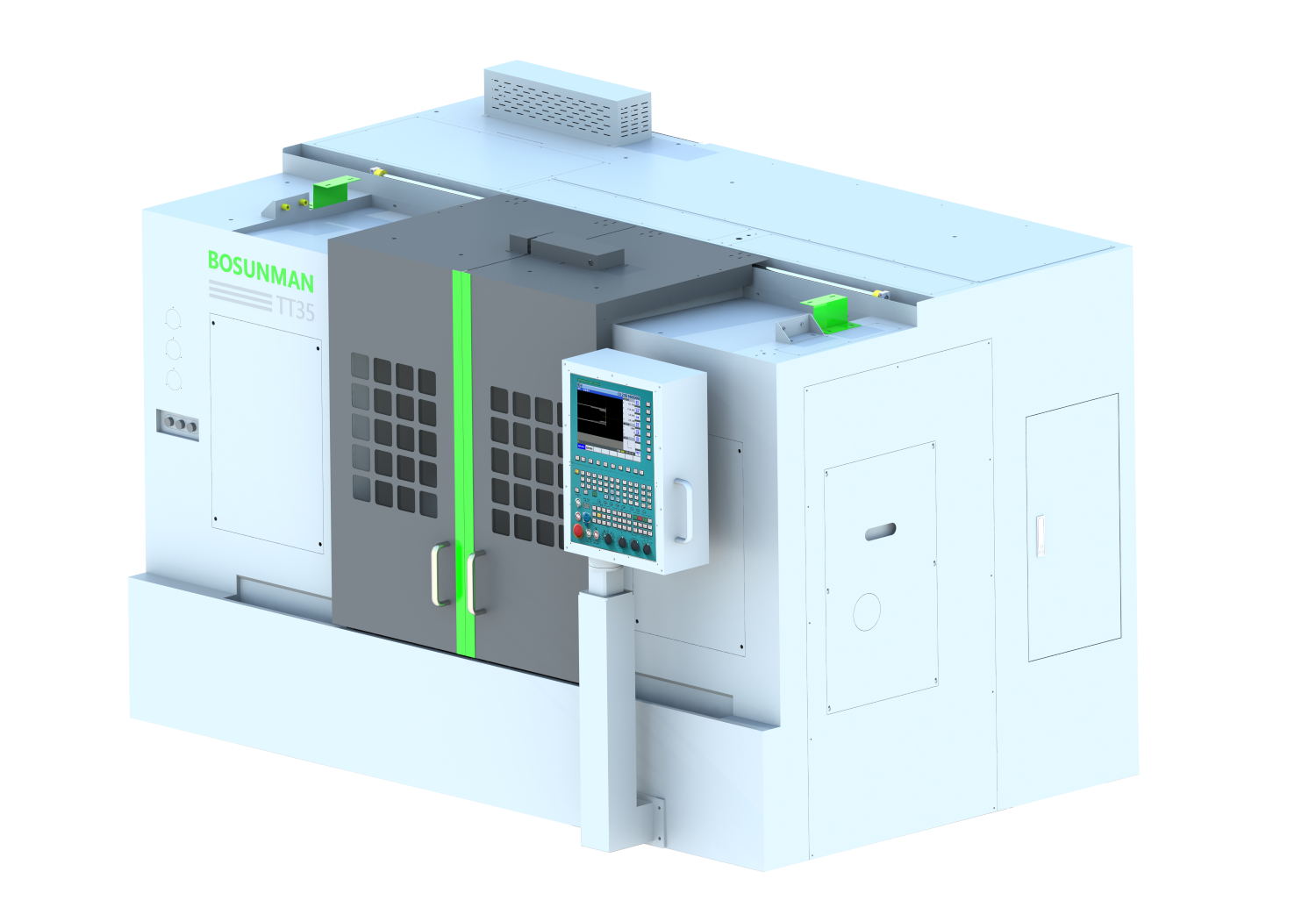

Machine tool performance structure characteristics

B2-GK30 high precision internal and external circular composite grinding machine series is a high-end CNC machine tool with independent intellectual property rights developed by our company on the basis of many years of CNC grinding machine design and manufacturing.

This machine tool adopts advanced flexible composite processing technology, and a variety of different combinations of grinding wheels form various series. Complete the grinding of outer circle, inner circle, end face, dimensional surface, non-circle, surface and other parts of the workpiece at one time, completely changing the traditional processing method of multi-machine tool sequential processing. It has the characteristics of high machining precision, high machining efficiency and high machining flexibility. Applicable to military, aerospace, aviation, shipbuilding, electronics, cutting tools, measuring tools, machine tools, automotive and other industries of precision machining field.

- The machine tool structure layout is reasonable, the overall protection, easy maintenance, in line with the requirements of ergonomics.

- The grinding wheel frame can be arranged with external grinding wheel, end external grinding wheel and internal phoenix grinding wheel at the same time, integrating dynamic and dynamic pressure shafting, dynamic pressure shafting and electric shafting. To meet the user's process requirements to the maximum extent.

- The machine can control up to 4 CNC axes (2 linear axes and 2 rotations) for multi-process agile and flexible grinding.

- The movement of the grinding wheel frame (X axis) is driven by the same service motor (or linear motor + closed high-precision guide rail) to ensure the accuracy, sensitivity and high responsiveness of the grinding feed. The movement of the table (axis) is driven by the AC co-service and ball screw pair. Wheel frame rotation (B axis is driven by torque motor (or the same motor), positioning accuracy of 2.5 ", to ensure the accurate displacement of multiple grinding wheels, and can achieve X-Z-B axis linkage to complete the shaped cylinder (curved surface) grinding.

- The workpiece rotation system can be configured with C-axis torque motor, Angle encoder drive, high-precision rolling bearing pumping, high rotation accuracy, high dynamic response :C-X axis linkage, to achieve non-circular and eccentric grinding, you can also choose servo motor (or three-phase AC motor) drive, rolling bearing shafting (or high-precision dynamic pressure spindle system), high rotation accuracy. Realize cylindrical grinding.

- A variety of diamond dressing devices can be selected (installed on the back side of the head frame) to achieve accurate numerical control dressing and automatic compensation.

- Imported active measuring device can be configured to achieve full closed-loop control of high-precision grinding processing.

Search

Search