Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

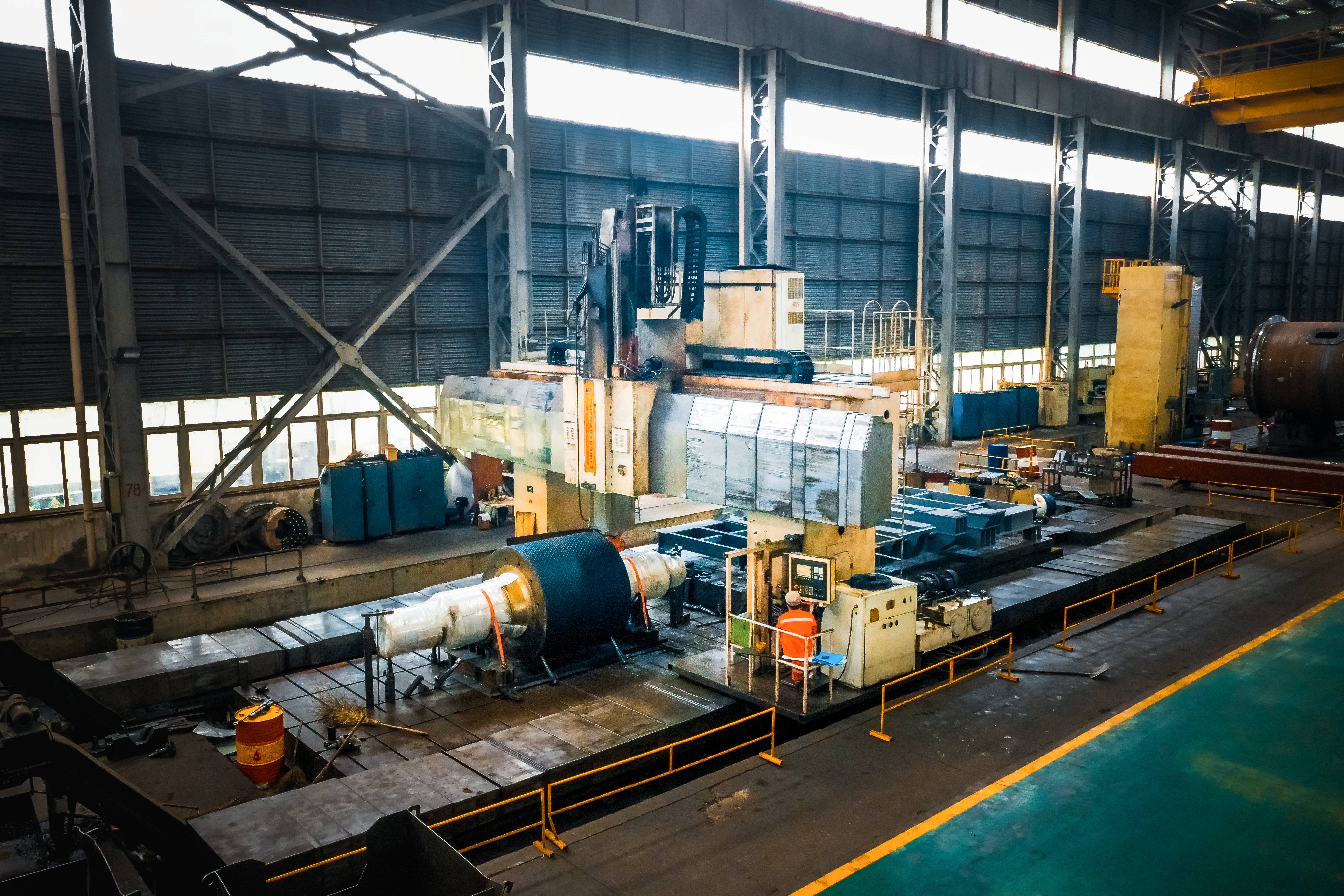

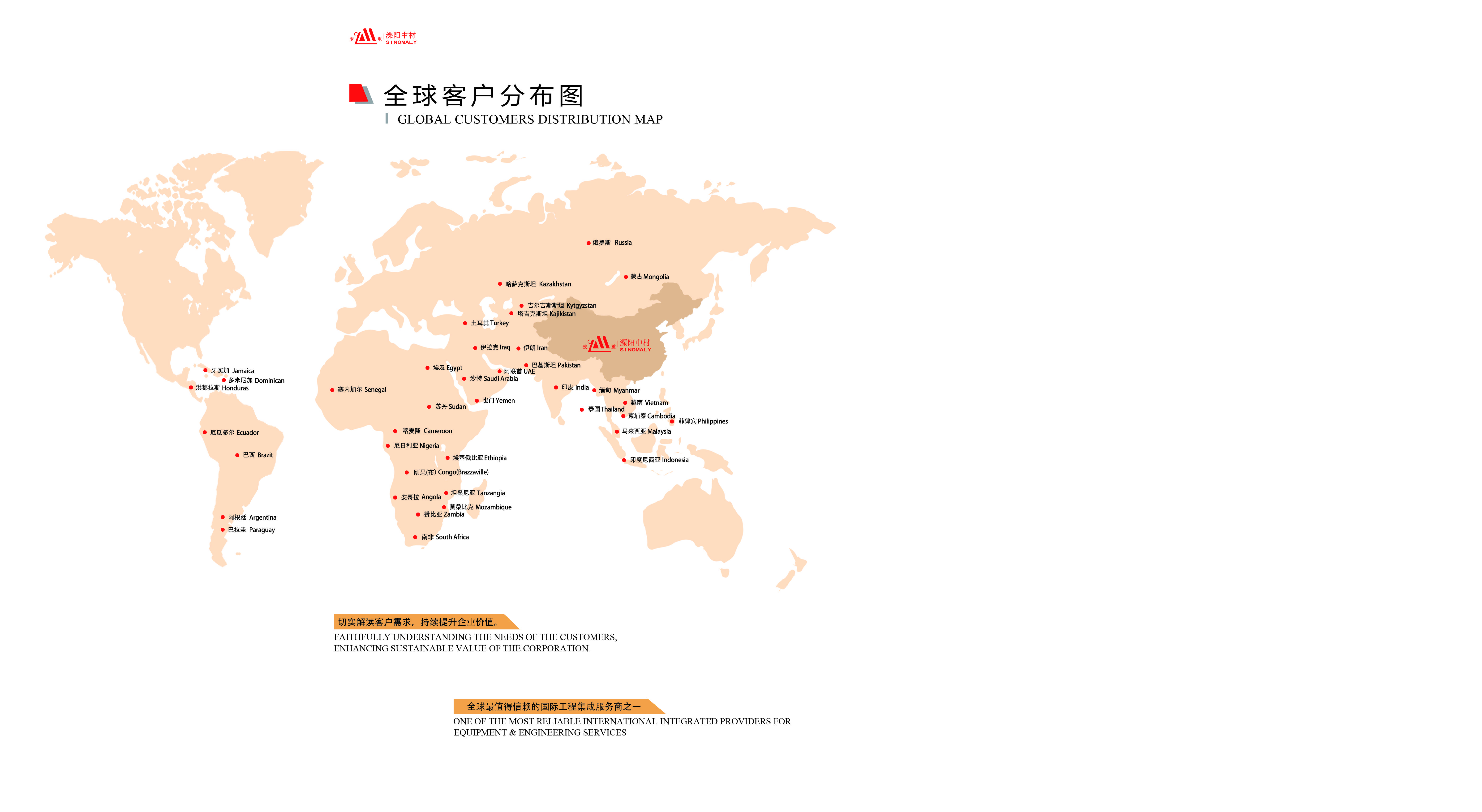

Apron feeders are used to transport a variety of large or loose materials from the material warehouse to the crusher, conveyor or other equipment, and do so in a horizontal or inclined direction. The apron feeders are widely used in building materials, metallurgy, coal, chemical and other industries for raw material handling or continuous production processes in order to carryout production connection, stream flow regulation, material pre-mixing and other work. Here at SINOMALY, we have decades of experience in the production of apron feeders, and are able to supply equipment with a single processing capacity of 3,000 tons/hour.

Apron Feeder Working Principle:

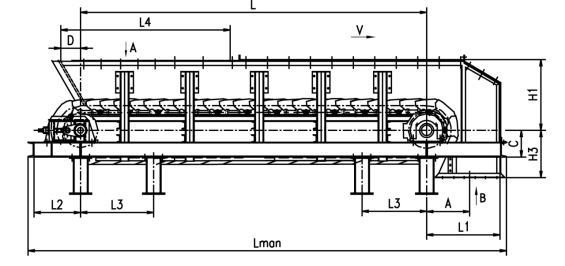

In the requirement of the production capacity, the apron feeder can be divided into three duties: heavy, medium and light. Among them, the heavy duty can transport larger granularity material, the width of the material is generally not greater than 60% of the width of the plate, the width of the chain plate is generally 1250-3150mm;Light and medium duties conveying material weight is not more than 140kg, per cubic meter bulk density is not more than 1200kg, chain plate width is generally 500-1250mm.The production capacity of the apron feeder depends on the actual loading width of the chain plate, the average height of the material layer and the running speed.

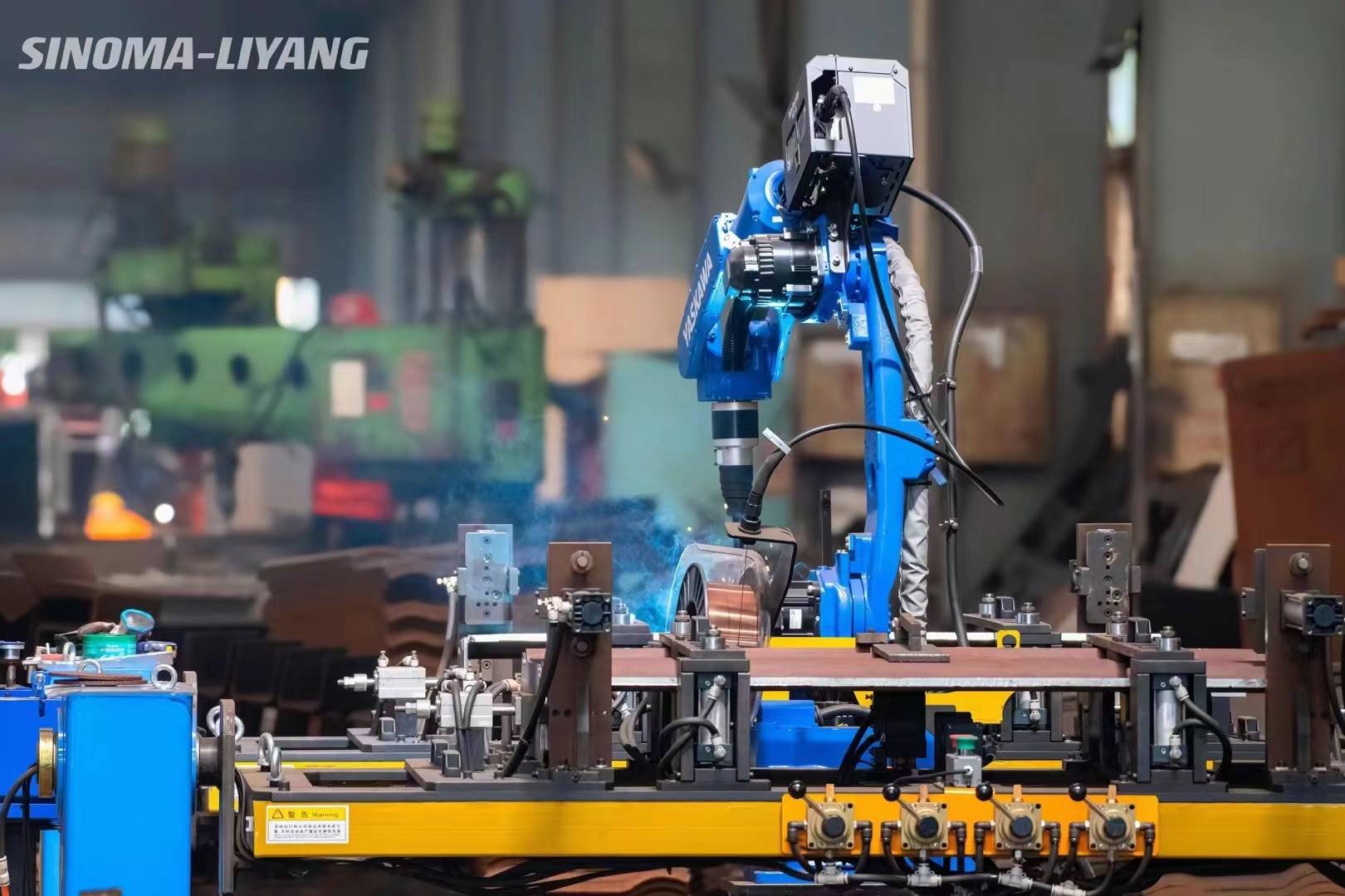

Taking heavy-duty apron feeder as an example, in the process of operation, the high strength caterpillar type chain is used as the traction chain, and the two chains bypass a pair of drive sprockets installed on the head of the frame and a pair of tensioning wheels at the tail of the frame to form a closed loop. An overlapping, heavy-duty structure of flight is installed on each link of the two rows of chains to form a continuous transmission line capable of carrying materials. The self-weight and the weight of the material are supported by a plurality of rows of supporting wheels, sprockets and slide rail beams installed on the frame. Transmission system driven by AC frequency conversion motor through coupling and reducer drive sprocket shaft, the material fed into the tail silo along the transmission line to the front of the discharge end, to achieve the purpose of continuous and evenly feeding to the downward working machinery.

Features of Our Apron Feeder:

Comparing with other competitors, our apron feeder is more reasonable in structure, simple and convenient in installation, disassembly and maintenance, and has the following advantages:

(1) Wider scope of application, more than 20 yeas experiences and continuously updating our apron feeder to state-of-art, figure out various of the material with sharp edges and corners and strong wear, and capable for handling high temperature material less than 400℃.

(2) Flexible and diverse in driving device configuration, between the driving motor and the reducer can be connected with the hydraulic coupling, to ensure the smooth start and overload protection; As an option, the chain driving type between the reducer and the main shaft is applicable which helps buffering and making the transmission ratio stable, high power transmission, adjustable center distance, easy to arrange and install; According to the layout, the drive shaft is configured with a backstop to prevent the reverse rotation of the chain plate; The customer has a flexible choice for a proper driving position layout (left, right, horizontal, inclined layout) according to their requirement on the apron feeder.

(3) The structure of wheel hub and rim of the drive sprocket and tensioning sprocket can be combined, and the wheel teeth can be replaced without disassembling the flights to reduce the amount of maintenance and maintenance costs; Reasonable design in the number of teeth of the drive sprocket, odd and even teeth drive alternately, so that a longer service life is achieved for the core parts; The replaceable gearless rim can ensure the correct and constant contact between the chain and the sprocket and prevent the tooth surface from gluing.

(4) Traction chain is applied by plate chain (light and medium) or tank chain (heavy), high strength, long service life.

(5) The head bearing seat is vertically connected to the frame to ensure that the bearing seat forces in the same direction as the working force, improve the bearing seat and the connecting bolt forces, and reduce the space size.

(6) Apply screw tensioning, the support using steel and bolt connection structure aesthetics and convenient assembly and disassembly. For heavy and super heavy tensioning device, a group of spring is added to buffer vibration absorption, tensioning screw through the center of the slide seat, to ensure reliable work; The screw of the tension device of the medium duty and light duty is located above the slide seat and placed under the inverted equilateral angle steel preventing the screw parts from pollution and damage.

Search

Search