Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

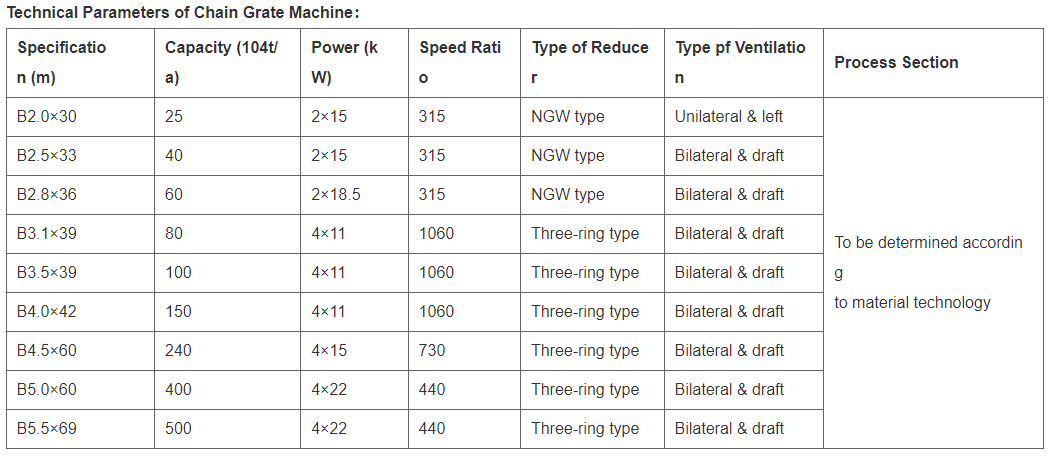

Introduction of Chain Grate Machines:

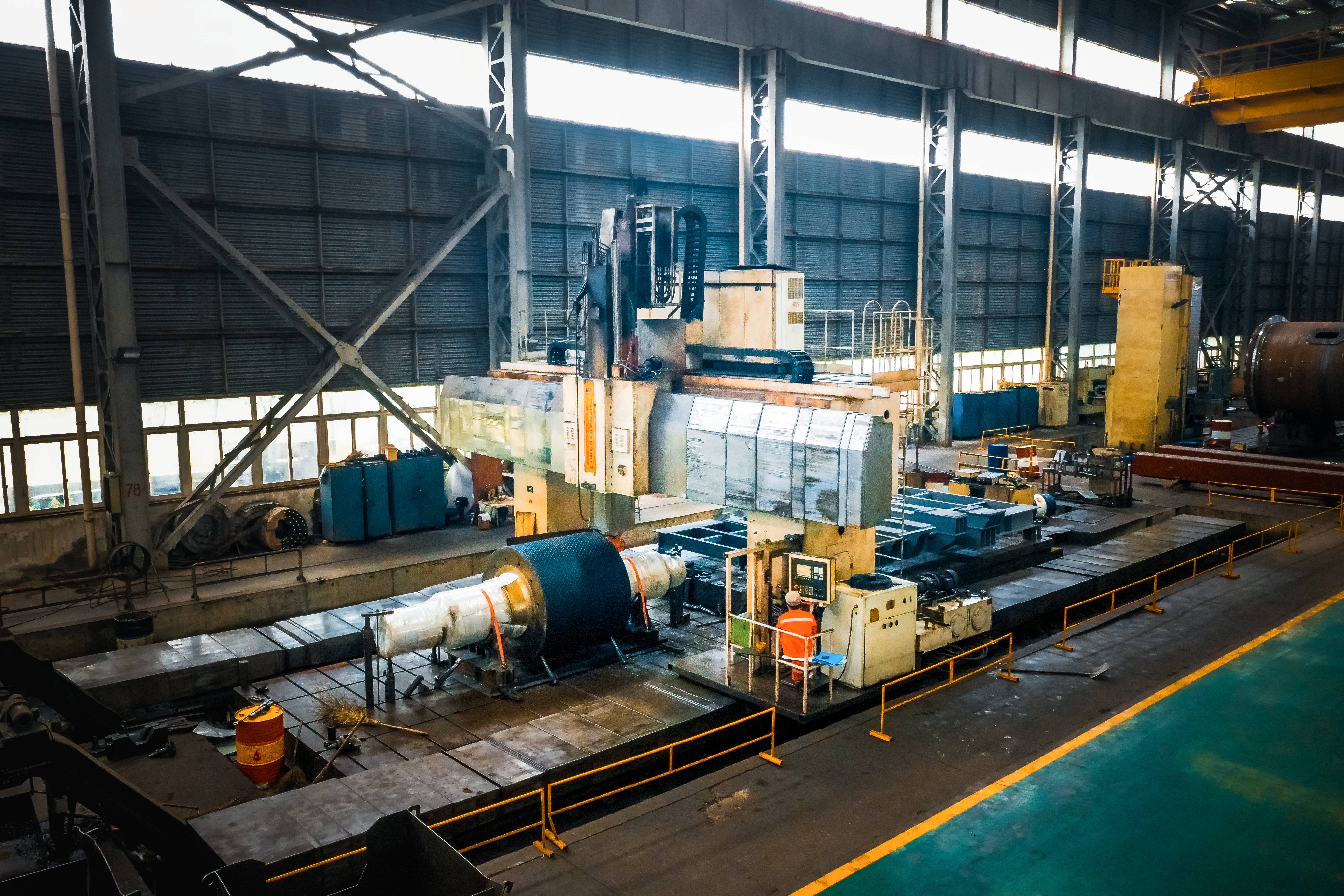

The Chain grate machine is a large non-standard equipment used in the traveling grate machine -rotary kiln process to burn pellets, and it is the core equipment of the three main machines on the process line. The Chain grate machine is mainly operated in parallel with non-standard chains under high temperature conditions, and the entire grate bed is drawn in a circular operation, so that the carried material enters from the tail and discharges from the head.

The Chain grate machine is mainly composed of the transmission device, traction head wheel, carrying device, tail redirection unit, sealing device, grate bed assembly, bellows unit, frame, cover body and other components.

The transmission device and the traction head wheel provide the power source for the entire equipment, bringing the traction grate bed to make a circular motion;

The carrying device supports the entire chain grate bed to carry and transfer materials;

The sealing device ensures that materials are transported in the entire sealed furnace and reduces heat loss;

The grate bed is the main carrier to transfer the materials;

The bellows unit is mainly used for ventilation or blasting;

The frame and cover, etc. are the accessory parts to ensure the entire equipment

Working principle of Chain Grate Machine:

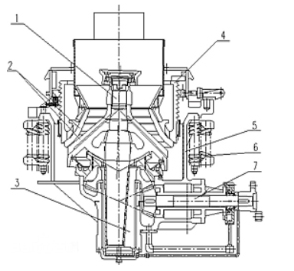

When the Chain grate machine is working, the motor drives the traction head wheel to rotate through the reducer, so that the traction head wheel drives the grate bed to move in parallel through the engagement of the assembled sprocket and chain links, and the material is continuously carried forward by the grate bed. The green balls prepared by the pelletizing mechanism are screened by the sieve distribution machine, and the qualified green balls (φ8~16mm) are evenly distributed on the cloth area at the tail of the grate machine. With the operation of the grate bed, the material balls pass through the blast section, the drying section I, the drying section II and the preheating section, and finally enter the rotary kiln through the shovel plate and the kiln tail chute. The blast section and the drying section I mainly remove the moisture contained in the material balls; the drying section II mainly removes the crystal water of the material balls; the preheating section mainly heats the material balls. The material ball completes the drying and preheating process in the chain grate machine, so that the material ball has a certain compressive strength, and it will not be broken or damaged during the roasting process in the rotary kiln.

The heat source used by this machine mainly comes from the high-temperature airflow at the end of the rotary kiln and the waste heat from the annular cooler and the traveling grate machine.

When the Chain grate machine is working, the motor drives the traction head wheel to rotate through the reducer, so that the traction head wheel drives the grate bed to move in parallel through the engagement of the assembled sprocket and chain links, and the material is continuously carried forward by the grate bed. The green balls prepared by the pelletizing mechanism are screened by the sieve distribution machine, and the qualified green balls (φ8~16mm) are evenly distributed on the cloth area at the tail of the grate machine. With the operation of the grate bed, the material balls pass through the blast section, the drying section I, the drying section II and the preheating section, and finally enter the rotary kiln through the shovel plate and the kiln tail chute. The blast section and the drying section I mainly remove the moisture contained in the material balls; the drying section II mainly removes the crystal water of the material balls; the preheating section mainly heats the material balls. The material ball completes the drying and preheating process in the chain grate machine, so that the material ball has a certain compressive strength, and it will not be broken or damaged during the roasting process in the rotary kiln.

The heat source used by this machine mainly comes from the high-temperature airflow at the end of the rotary kiln and the waste heat from the annular cooler and the Chain grate machine.

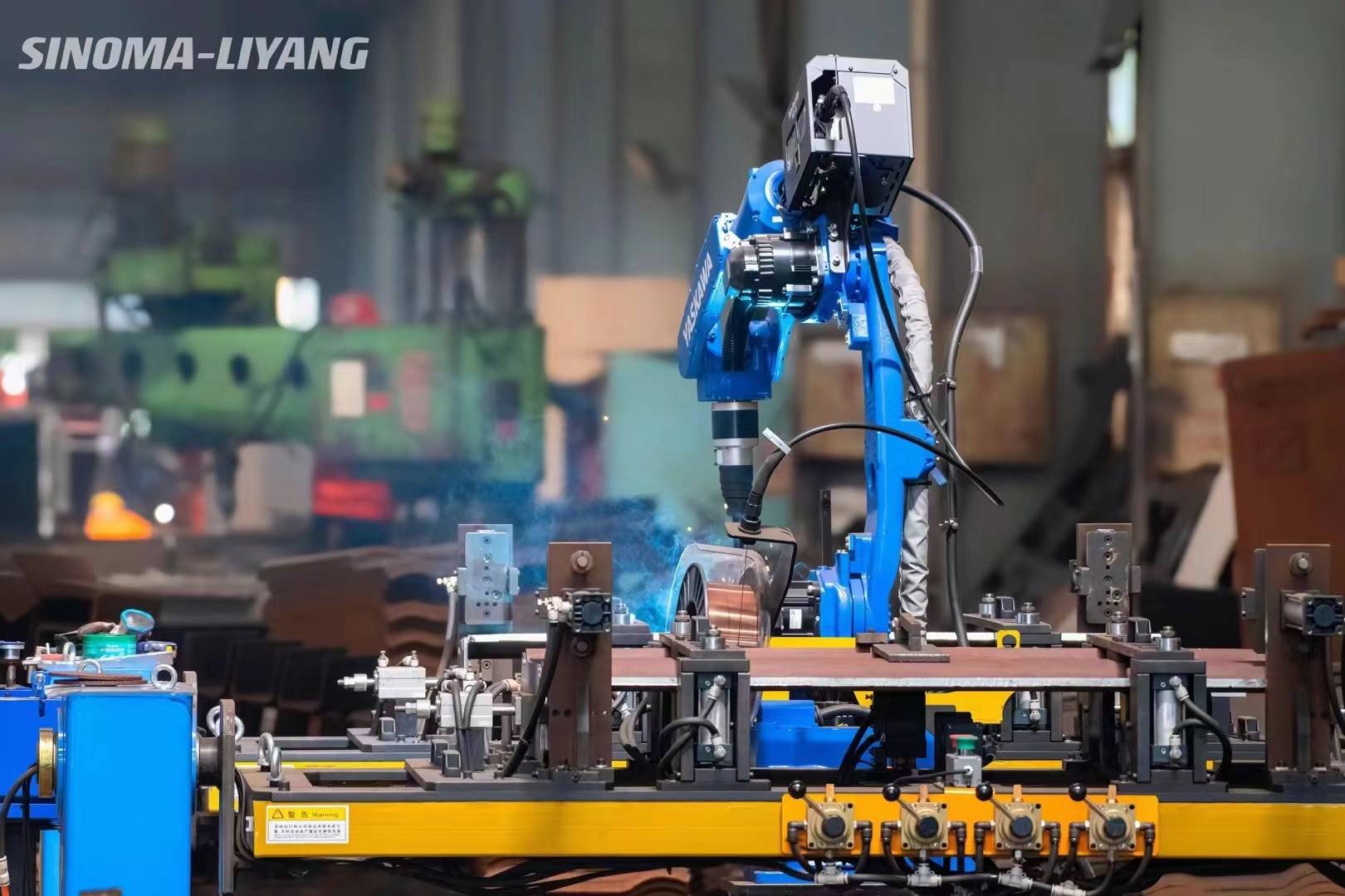

Features of Chain Grate Machine:

1) Flexible transmission technology can make the equipment automatically adapt to the thermal expansion of the main shaft of the traction head wheel.

2) Connected bellows structure, more uniform air draft, and smaller temperature difference in the same process section.

3) The grate bed has an automatic tensioning structure, which automatically tensions the thermal expansion and elongation of the grate bed.

4) The automatic reset device of the grate board forcibly make the grate board to return to its place, to prevent affecting the state of the cloth.

5) The staggered engagement technology can compensate the difference in thermal expansion between the grate bed and the main shaft.

6) The self-adaptive linkage flexible guide rail mechanism can completely avoid the collision and jam of the grate plate and other fixed parts.

7) Unique sealing technology, which can effectively prevent air from flowing into other chambers and reduce consumption of energy.

Search

Search