Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

Product features:

Self-developed patented high hydrostatic spindle, providing <1.5μm rotation accuracy

High rigidity spindle, easy to deform, suitable for heavy cutting

The grinding wheel line speed can reach 50m/s, and the grinding precision is high to ensure the surface finish of the workpiece

High rigidity bed

High quality Mihanna cast iron produced by Xingfuxiang, using low frequency furnace to ensure the quality of castings;

After normalization treatment and 1.5 years of natural aging, eliminate the internal stress of the bed, ensure the accuracy of the bed, and ensure no deformation;

High wear resistance, high rigidity, high frequency hardening, precision grinding, manual spatulation; Stable bed structure design, the machine has a high overall accuracy;

Hydrostatic spindle

The main shaft is made of SNCM-220H advanced alloy steel imported from Japan. After tempering, cryogenically and precision grinding, the main shaft has high precision and high speed.

The spindle adopts high hydrostatic pressure patent, can form 20-25KG/cm2 high pressure oil film, so that the spindle is suspended in it, no contact with the spindle in the working state, no friction, high rigidity, no wear, can ensure high-precision machining and ultra-long working life;

High hydrostatic spindle provides 3-year maintenance;

High precision grinding

Xingfuxiang's own production and assembly of the spindle, rotation accuracy <1.5μm, bring high precision grinding performance;

The fastest speed of the grinding wheel is 50m/s (hydrostatic pressure), 35m/s(dynamic pressure) to ensure the surface finish of the workpiece; Guide wheel stepless speed change (10~300rpm), to adapt to different processing needs

Up and down slide

Automatic lubrication system, the upper slide board with dovetail slide rail, the lower slide board with double Λ guide rail, to provide smooth and accurate feed;

The rotation Angle of the upper slide plate ranges from +6° to -6°, which can be easily and accurately adjusted to meet the needs of stopping grinding;

During grinding operation, the upper slide plate has an adjustment range of +6°~-5°, which is used to adjust the contact surface between the grinding wheel and the workpiece;

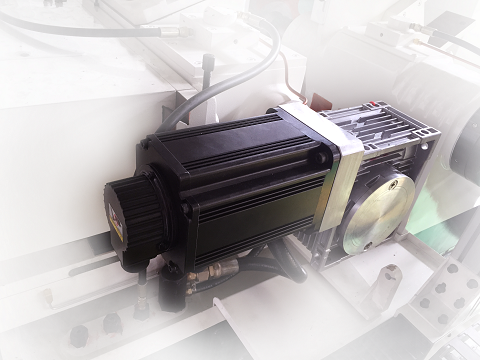

Adjusting wheel servo motor

Adjusting wheel motor adopts servo motor, 10-300rpm stepless speed, can be adjusted to superior linear speed;

The servo motor and the variable speed machine are placed on the side of the guide wheel shaft, which can reduce the vibration and improve the stability of grinding

Search

Search