Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

1, background analysis

The traditional steel plate ultrasonic automatic flaw detector using water film method coupled flaw detection equipment, probe type for a hair of three receives and a hair of four receives longitudinal wave direct method of detection, this detection method can only detect defects parallel to the rolled surface of the steel plate, steel plate, the effective detection of the scope of detection and detection capabilities are limited. The main performance:

1, can not detect the non-delamination defects on the edge of the steel plate (such as Ø1.6mm vertical through holes).

2, low detection sensitivity (greater than 5mm flat bottom hole), can not find smaller defects.

3, the detection of the steel plate on the upper and lower surface of the large blind spot (greater than 3mm), the detection range is insufficient.

The above problems easily caused by the steel plate around the edge and the steel plate on the upper and lower near-surface defects leakage detection. It can not meet the requirements of high quality steel such as nuclear power steel plate, military steel plate, steel plate for submarine pipelines, etc. It seriously affects the quality inspection of steel plate and brings hidden danger to the safe use of steel plate.

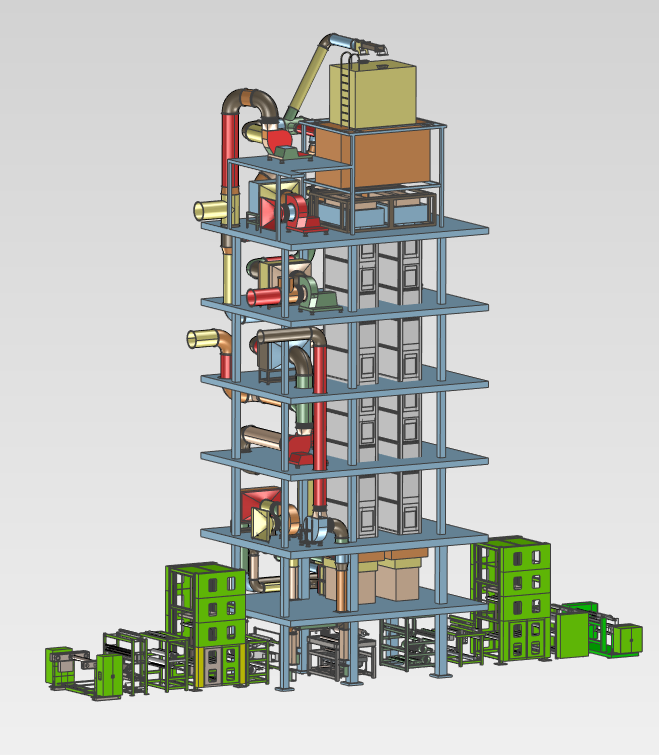

2、Products

Phased array technology: phased array probe is composed of dozens of hundreds of miniature piezoelectric wafers, constituting a transducer array, through the establishment of focusing rules to control the emission and reception time of each array unit, thus generating a plurality of ultrasonic beams, as well as controlling the angle of the beam, the depth of focus, the focusing dimensions, etc., to achieve the rapid scanning and imaging of the workpiece.

Phased array technology features:

(1) high sensitivity: phased array probe using 128 array elements, aperture ø0.6mm and 1.2mm combination of ways, can achieve ø2mm flat bottom hole equivalent detection sensitivity; through different settings, you can make defects in the size of the error is controlled within 5%.

(2) can effectively reduce the blind zone: the use of phased array probe focus continuously adjustable characteristics, can be adapted to the detection of different thicknesses of 4mm-230mm steel plate, the upper and lower table blind zone is less than 1.5mm.

(3) Detecting edge delamination defects: with independent phased array transverse wave detection device, the use of ultrasonic sound speed direction continuously adjustable and fan sweep characteristics, can detect defects in different directions, including the edge of the non-delamination defects, can detect Ø1.6mm vertical through-hole defects.

![[Used] laser](https://cdn.sumecdtx.com/equipment/20230818/928f9346aceb42e3b60670c380399f59.jpg)

Search

Search