Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

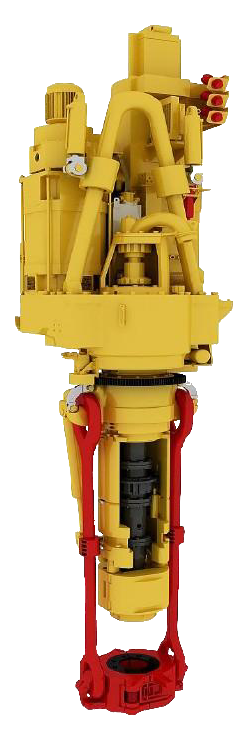

ZJH member type pneumatic diaphragm regulating valve

overview

The ZJHP/ZJHM series of precision and small pneumatic membrane regulating valves are a new generation of actuators that meet IEC standards developed by our factory absorbing advanced domestic and foreign technology. They are composed of a multi-spring zero-adjustable actuator, a low-flow resistance sleeve, and a single-seat regulating valve without a lower cover. The volume ratio is 1/3 smaller, the weight ratio is 1/3 smaller, and the circulation capacity is 1/3 larger. The center of gravity is low, the earthquake resistance is good, and the installation is simple; the performance indicators are better than similar products, equivalent to foreign CV3000 series control valves, and are widely used in chemical, petroleum, light industry, power station, metallurgy and other industries.

Structural principles, structure

Accept the control signal pressure output by the regulator's standard electrical signal (via the electro-pneumatic positioner or electro-pneumatic converter), change the valve opening to change the flow rate of the regulated medium, so that parameters such as flow rate, pressure, temperature and liquid level are adjusted to realize automation of the production process. After the external pneumatic pressure signal is input into the membrane chamber, this pressure acts on the membrane to generate thrust. This thrust compresses the spring set and moves the push rod to drive the valve stem to open (close) the valve core until the thrust force and the spring set are compressed. The reaction force is balanced and stable at a certain position on the stroke. According to the above principles, it can be seen that the valve core displacement has a certain proportional relationship with the input pressure signal.

ZJHP series gas | Dynamic single-seat regulating valve ZJHM series pneumatic sleeve regulating valves HTS single-seat regulating valve HCB cage type double-seat regulating valve | ||||||||||||||||

Model corresponding to CV3000 | HLS small bore single seat regulating valve | ||||||||||||||||

Nominal diameter DN(mm) | 20 | 25 | 3 2 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | ||||

10 | 12 | 15 | 20 | ||||||||||||||

Rated flow coefficient Cv | High-precision flow characteristic valve core | 1.6 | 2.5 | 4.0 | 6.3 | 10 | 1 7 | 24 | 44 | 68 | 99 | 175 | 275 | 360 | 630 | 900 | 1440 |

High capacity flow characteristic valve core | 1.8 | 2.8 | 4.4 | 6.9 | 11 | 2 1 | 30 | 50 | 85 | 125 | 200 | 310 | 440 | 690 | 1000 | 1600 | |

Rated stroke (mm) | 10 | 16 | 25 | 40 | 60 | 100 | |||||||||||

Effective film area cm² | 280 | 400 | 630 | 1000 | 1600 | ||||||||||||

inherent adjustable ratio | 50:1 | ||||||||||||||||

Nominal pressure MPa | 1.6、4.0、6.4 | ||||||||||||||||

Operating temperature ℃ | Normal temperature type: -20  ̄ 200,-40  ̄ 250,-40  ̄ 450 | ||||||||||||||||

Ambient temperature ℃ | -30~+70 | ||||||||||||||||

Air source pressure KPa | 0.14、0.25、0.40 | ||||||||||||||||

Spring range Kpa | 20~100(basic type), 40~200, 80~240 | ||||||||||||||||

joint threads | G1/4",M16X1.5 | ||||||||||||||||

Search

Search