Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

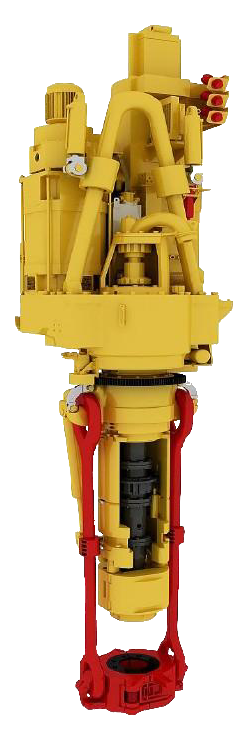

Structural characteristics and use

1. Small pressure loss: When fully opened, the water loss is zero, the flow channel is completely smooth, and the medium will not deposit in the cavity of the valve body.

2. Resistance to particle wear: There is a shearing effect between the spherical cap with the V-shaped opening and the metal valve seat. During the closing process, the spherical cap only leans against the valve seat at the last moment, and no friction is formed. The valve seat is made of wear-resistant nickel alloy and is not easy to be washed and worn, so it is suitable for use with fibers, tiny solid particles, pulp, etc.

3. Suitable for high flow rate media: Straight flow channel, strong eccentric crankshaft makes it suitable for high flow rates and no vibration.

4. Long life: There are no vulnerable parts. Due to eccentricity, there is no friction between the sealing surfaces when the valve is opened and closed, so the service life is long.

5. Convenient maintenance: When the valve is repaired, it is not necessary to remove it from the pipeline. As long as the valve cover is opened, it can be repaired.

6. Widely used in water, sewage, containing tiny solid particles, water, steam, gas, natural gas, oil products, etc.

Main component materials

Body,Bor | GB | NOE | c 【F | * :N12Mo2T | Z315CMmiN | |||||

M | WCE | CFE | CFBN | WOE | ||||||

GB | ZG2Cr13 | ZG1Cr18Ni9Ti/ surface special features | ZGOCr18Ni12MoTi/ Go to face for special treatment | ZG15Cr1Mo1V Special surface treatment | ||||||

ASTM | CA15 | CF8+HF | CF8M+HF | WCg+H | ||||||

GB | 2Cr13 | 1Cr18Ni9Ti | 0Cr18Ni12Mo2Ti | 25Cr2Mo2V | ||||||

ASTM | 420 | 304 | 316 | F224 | ||||||

GB | PTFE | 2Cr₁3 | PTFE | 1Cr18Ni9Ti | PTFE | DCr18Ni12Mo2Ti | D517 | |||

ASTM | PTFE | 420 | PTFE | 304 | PTFE | 316 | HF | |||

Packing | GB | PTFE | Xinjiang lex | nite | PTFE | lex gr aphit | PTFE | Ruanshi Yu AovH1 g | ||

ASTM | PTFE | lex | Wang Shi gr | hite | PTFE | flexible graphite lex e graohin | PTFE | hite | ||

GB | 35 | 0Cr18Ni9 | DCr18Ni9 | 5Cr1Mo1V | ||||||

ASTM | A193 B7 | A320-B8 | A320-B8 | A193 B16 | ||||||

GB | 45 | 0Cr18Ni9 | 0Cr18Ni9 | 20CrMo | ||||||

ASTM | A1942H | A194-8 | A194-8 | A194-4 | ||||||

SPQ47F/H/Y-16/25 SPQ347F/H/Y-16/25 SPQ647F/H/Y-16/25 SPQ947F/H/Y-16/25

Main connection size

External Chief E 10 | Connecting size C o n ectlnn clm | enlonslmm] | Tight sealing surface S e a l i n g | Flange Houcheng | EH | ||||||

L | D | K | f :m quantity aty(n) specified & | d | |||||||

N | |||||||||||

1.6MPa |

g | 178 | 165 | 125 | M16 | 99 | 20 | 44 | |||

8 | 190 | 185 | 145 | M16 | 18 | 20 | 104 | ||||

8 | 203 | 200 | 132 | 20 | 120 | ||||||

8 | 229 | 220 | 1 | Mie | 156 | 22 | 140 | ||||

125 | 254 | 250 | 210 | M16 | 184 | 22 | 170 | ||||

150 | 267 | 285 | 240 | M20 | 211 | 24 | 190 | ||||

200 | 292 | 340 | 295 | M20 | 268 | 24 | 246 | ||||

250 | 330 | 405 | 355 | M24 | 319 | z | 26 | 296 | 10 | ||

300 | 355 | 460 | 410 | M24 | 370 | n | 28 | 350 | 10 | ||

350 | 450 | 520 | 470 | M24 | 429 | n | 30 | 410 | 10 | ||

40 | 530 | 580 | 525 | M27 | 400 | 32 | 450 | 10 | |||

450 | 580 | 640 | 585 | M27 | 548 | 40 | 516 | 12 | |||

500 | 660 | 715 | 650 | M30 | 609 | 44 | 576 | 12 | |||

600 | 680 | 840 | 770 | M33 | 720 | 54 | 690 | 12 | |||

700 | 900 | 910 | M33 | 794 | 40 | 760 | 12 | ||||

800 | 1000 | 1025 | 90 | M36 | 901 | 42 | 862 | 12 | |||

900 | 1100 | 1125 | 1050 | M36 | 1001 | 44 | 962 | 12 | |||

1000 | 1200 | 1255 | 1170 | M39 | 1112 | 46 | 1076 | 12 | |||

200 | 1300 | 1485 | 390 | M45 | 1328 | 52 | 1282 | 12 | |||

400 | 1500 | 0 | M45 | 58 | 1482 | 12 | |||||

600 | 1800 | 80 | M52 | 64 | 12 | ||||||

1800 | 2100 | M52 | 1950 | 68 | 15 | ||||||

2000 | 2300 | 220 | M56 | 70 | 15 | ||||||

2.5MPa | 50 | 178 | 125 | Ad18 | 99 | 20 | 84 | ||||

65 | 190 | 146 | 118 | 22 | 104 | ||||||

00 | 203 | 160 | M16 | 132 | 24 | 120 | |||||

100 | 229 | 190 | M20 | 156 | 24 | 142 | |||||

125 | 254 | 220 | M24 | 184 | 26 | 162 | |||||

150 | 267 | 250 | M24 | 211 | 28 | 192 | |||||

200 | 292 | 310 | M24 | 274 | 30 | 252 | A | ||||

250 | 330 | 370 | M27 | 330 | 32 | 304 | 10 | ||||

300 | 355 | 430 | M27 | 389 | 34 | 364 | 10 | ||||

350 | 450 | 620 | 490 | M30 | 448 | 38 | 418 | 10 | |||

400 | 530 | 580 | 550 | M33 | 503 | 40 | 472 | 10 | |||

450 | 580 | 640 | 600 | M33 | 548 | 46 | 520 | 12 | |||

500 | 680 | 715 | M33 | 609 | 48 | 580 | 12 | ||||

600 | 680 | 840 | 0 | M36 | 720 | 58 | 684 | 12 | |||

700 | 900 | 910 | 875 | M39 | 820 | 50 | 780 | 12 | |||

800 | 1000 | 1025 | 990 | M45 | 928 | 54 | 882 | 12 | |||

900 | 1100 | 1125 | 1090 | M45 | 1028 | 58 | 982 | 12 | |||

000 | 1200 | 1255 | 1210 | M52 | 1140 | 62 | 1086 | 12 | |||

200 | 1300 | 1485 | 1420 | M52 | 1350 | 70 | 1296 | 12 | |||

400 | 1500 | 1685 | 1640 | M56 | 1560 | 76 | 1508 | 12 | |||

1600 | 1800 | 1930 | 1860 | M56 | 1780 | 84 | 1726 | 12 | |||

2100 | 2130 | 2070 | M64 | 1985 | 90 | 1920 | 15 | ||||

20 | 2300 | 2345 | 2300 | M64 | B | 2150 | 15 | ||||

Search

Search