Post Requirements

Post Requirements

Post Requirements

Post Requirements

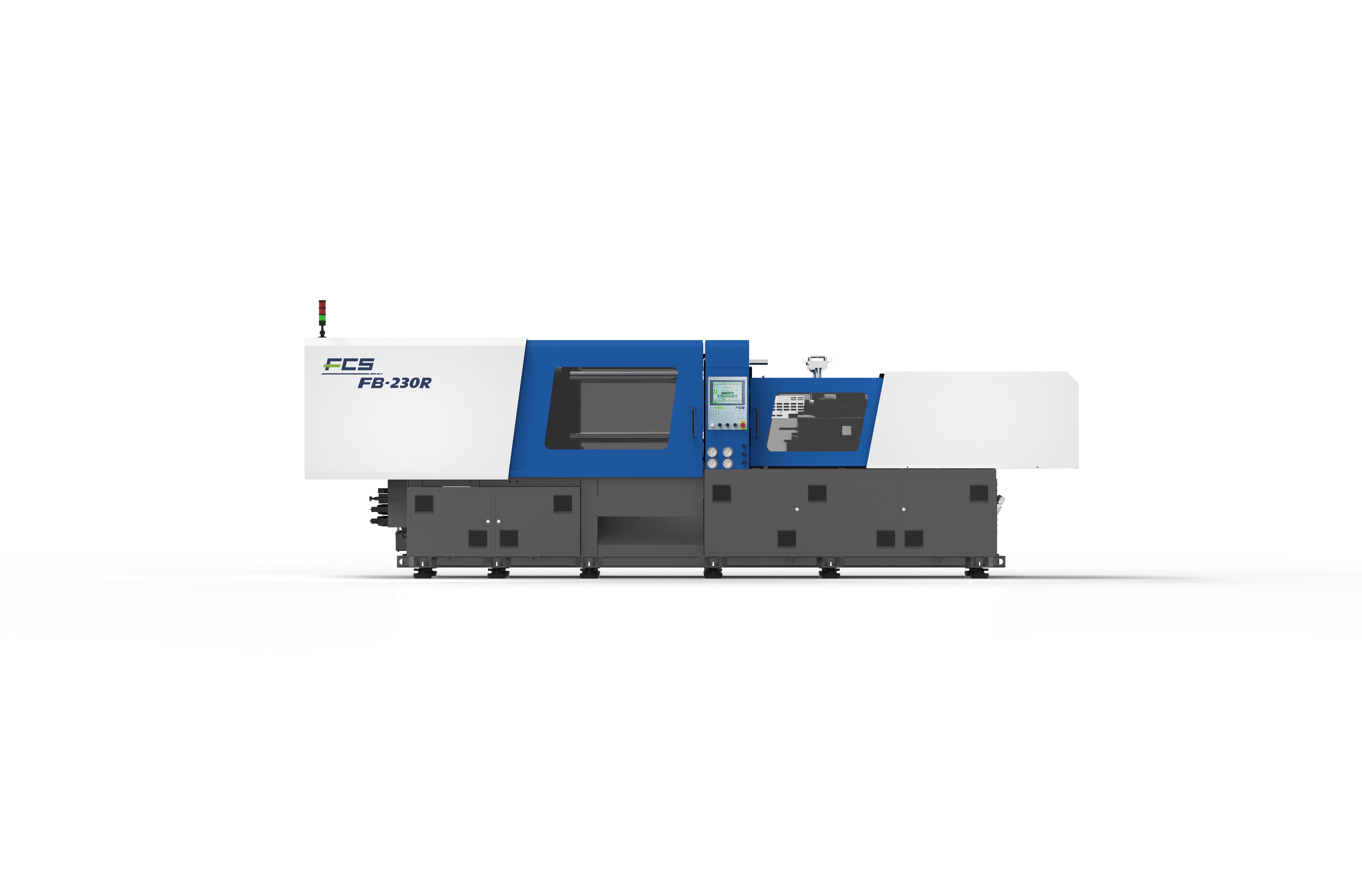

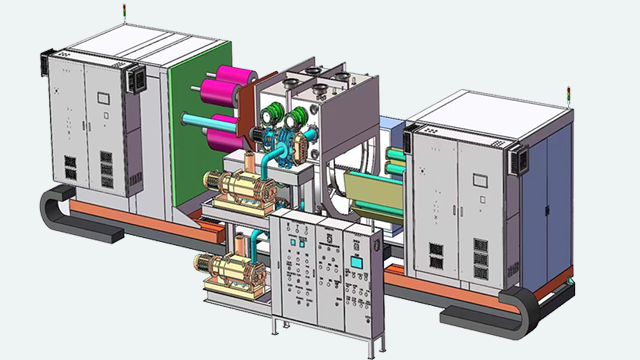

Product information

The main technical parameters:

Power: Three phases, 5kW, 380V, 50Hz/60Hz

Qi pressure: 3 ~ 6 kg/square centimeter per square meter

Speed: 25 boxes/minute

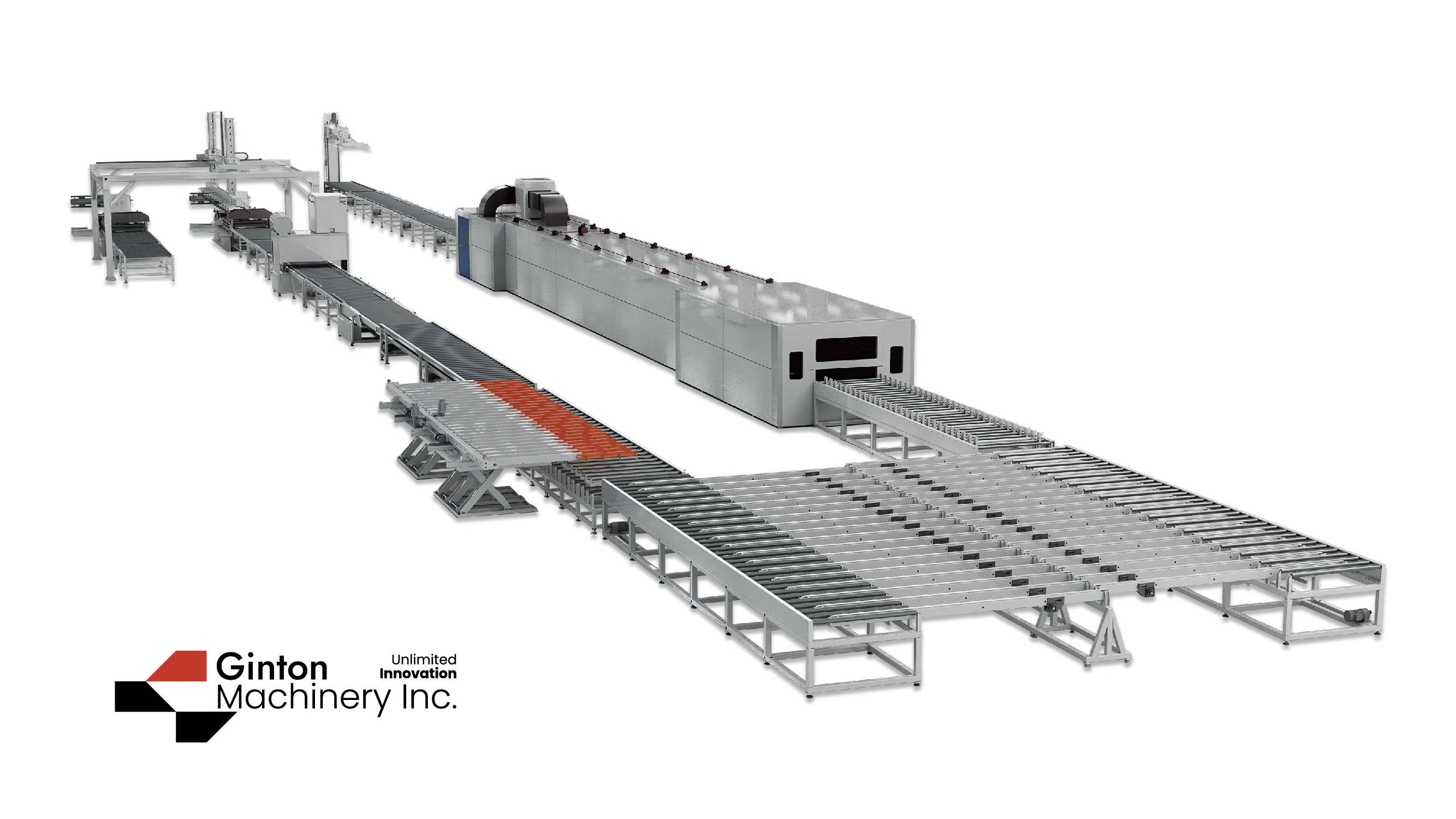

For random cargo trays, palletizing robots are a good choice. Nevertheless, robotics also face more problems. If it is produced at a higher speed, it will be more difficult.

A random loading robot palletizer requires special software. It is a huge progress through software and robotal gallery machines with other parts of the production line.

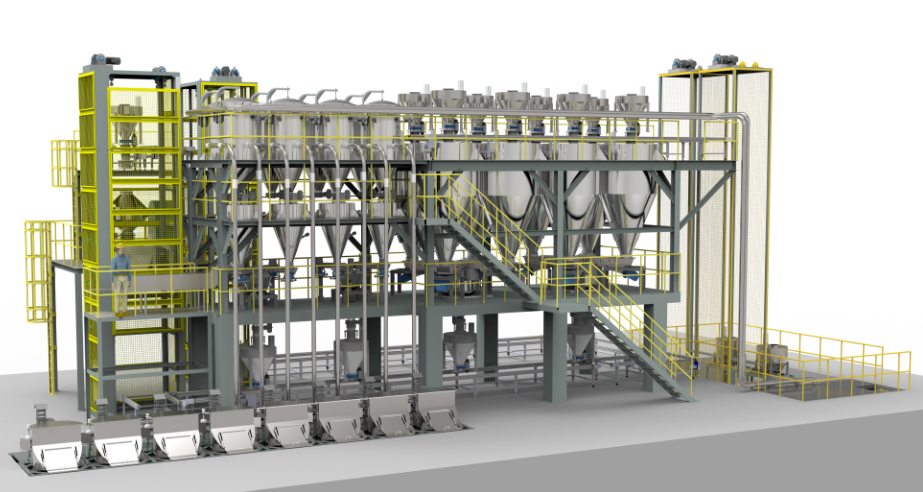

A robot used to build a random market can integrate the warehouse management system (WMS) that enters the factory. Ideally, it will become the front section of WMS and coordinate with the warehouse software to produce a mixed cargo tray.

Precision software can also meet the demand for the upper market. Generally speaking, this means that after the product is regional, some or all the labels of the packaging container must be outward. Robotics is also another harsh application: freezing puzzle in the frozen warehouse. In the field of consumer commodity packaging, it is one of the most difficult jobs in a freezing warehouse. Workers have to frequently work alternately to maintain their body warmth, which indirectly reduces work efficiency and improves labor costs.

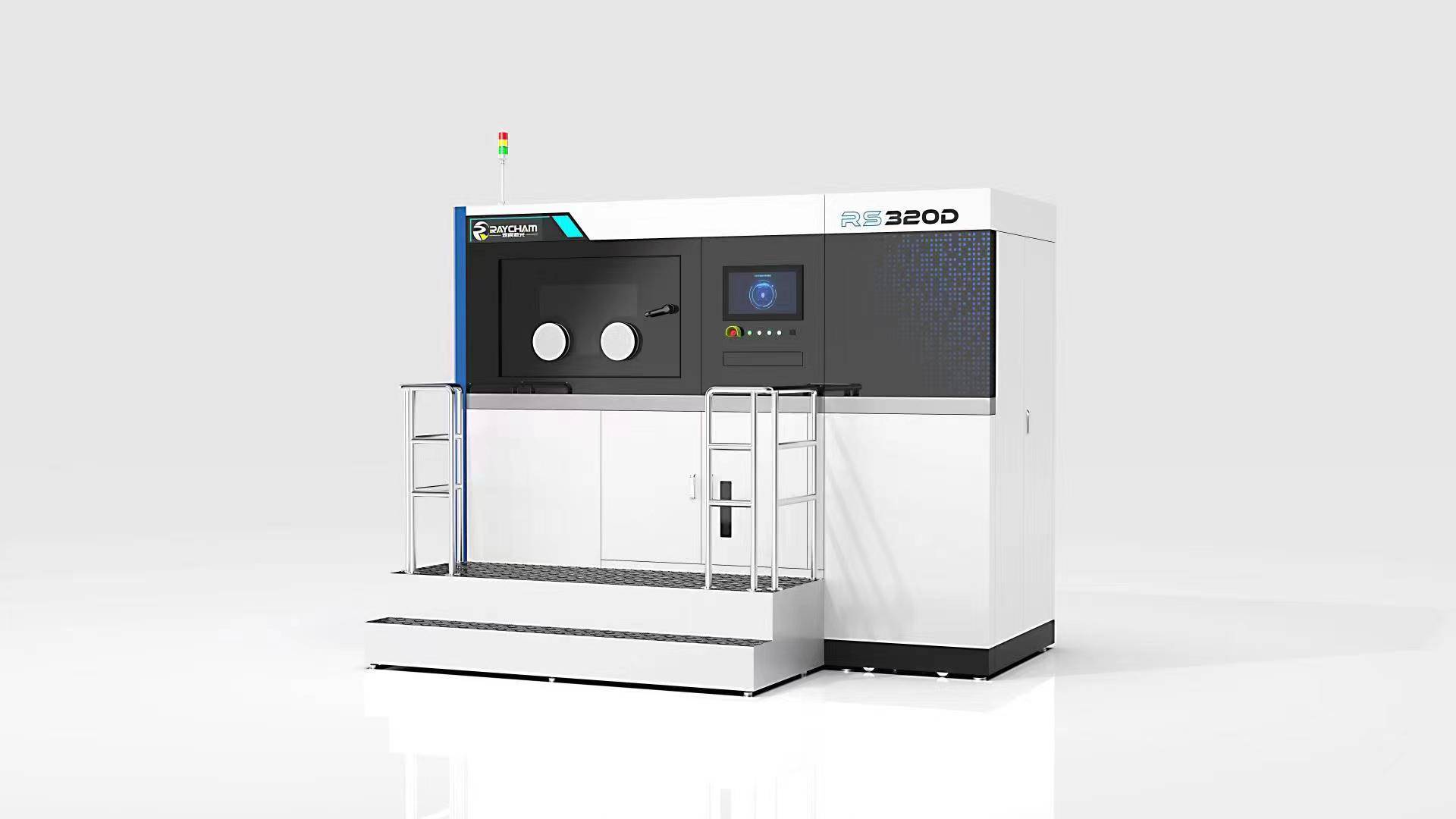

Features:

1. Simple structure and few parts. Therefore, the failure rate of components, reliable performance, simple maintenance and maintenance, and less in inventory parts.

2. Covering a small area. It is conducive to the layout of the production line in the customer's plant and can leave a larger warehouse area. Calculating robots can be set in a narrow space and can be effectively used.

3. Strong applicability. When the size, volume, shape, and pallets of the customer's products change, it only needs to be modified slightly on the touch screen, which will not affect the normal production of the customer.

The mechanical palletizer changes are quite troublesome or even unrealized.

4. Low energy consumption. The power of the mechanical palletizer is around 26kW, and the power of the palletizer robot is about 5kW. Greatly reduces the operating cost of customers.

5. All control can be operated on the control cabinet screen, and the operation is very simple.

6. Just position the starting point and placement point, and the method of teaching is simple and easy to understand.

Search

Search