Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

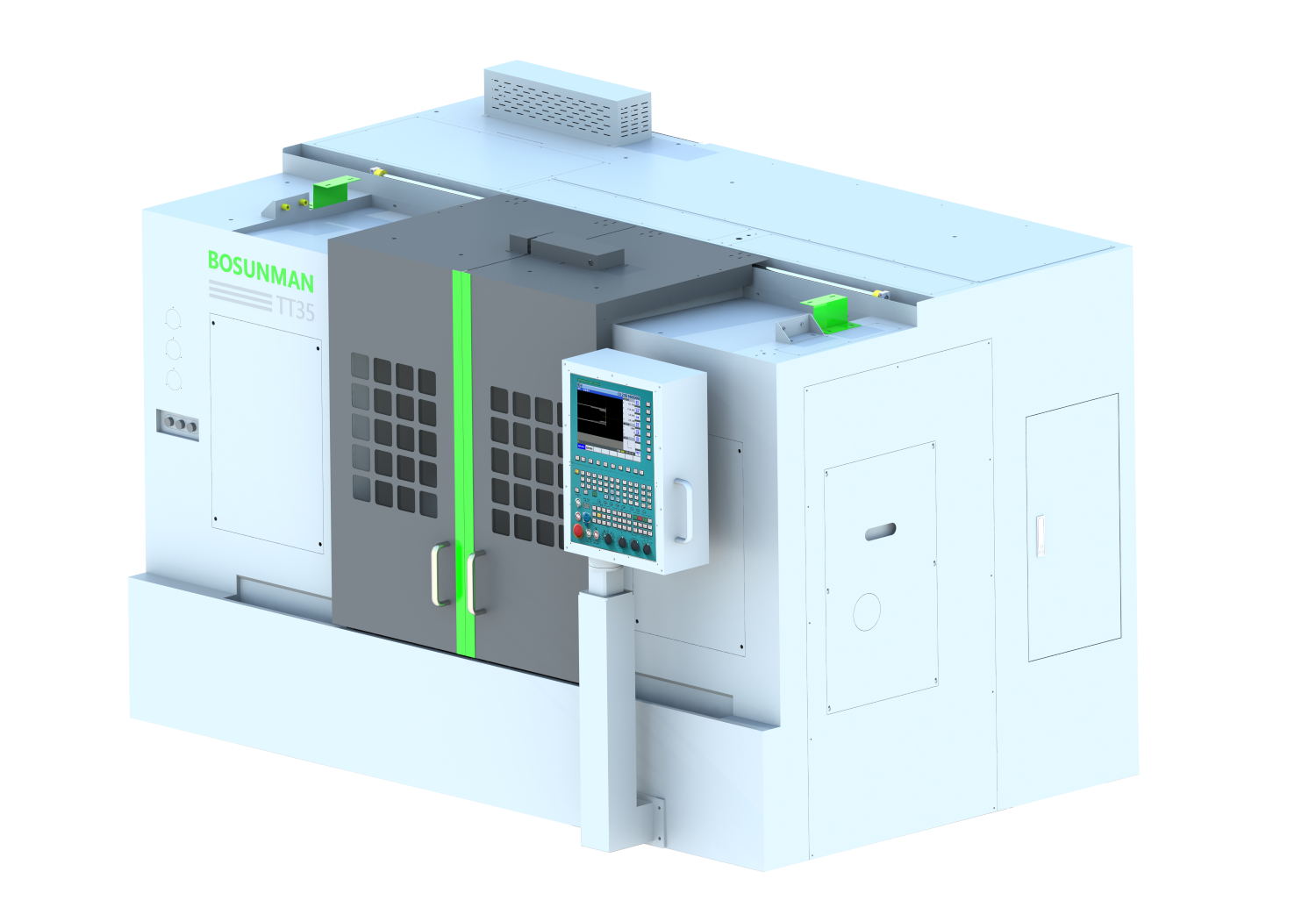

Machine tool introduction

SKGC series CNC high speed hobbing machine is suitable for all kinds of high precision external cylindrical gear processing, processing accuracy GB 8-9 level. Optional milling inner tooth headstock and rear column. The equipment can be widely used in engineering machinery, forging, wind power, port machinery and other industries, internal and external gear processing.

SKGC series CNC high speed hobbing machine standard configuration maximum machining diameter Φ1250, Φ2000, Φ3000, Φ4000, Φ5000 and other specifications, the maximum modulus can be 40mm, suitable for a variety of internal/external, straight/oblique gear processing.

Machine tool characteristics

1. The machine tool hob spindle motor is transmitted to the hob spindle through the high-precision gear pair, and the end gear of the hob spindle adopts the anti-backlash mechanism.

2, the hob spindle support adopts static bearing structure, which improves the transmission rigidity and torsional vibration resistance.

3. The spindle of the tool holder adopts high-precision HSK interface, and the built-in automatic tool clamping system provides high accuracy, stiffness and balance for the spindle. Avoid tool wear due to insufficient tool system stiffness or vibration to increase tool life.

4, equipped with double worm gear double worm anti-backlash turntable, worm gear pair accuracy reaches DIN2 level; Full static guide rail, strong bearing capacity, good dynamic response characteristics, high motion resolution.

5, the X axis bed guide rail is a combination of steel guide rail, plastered sliding surface and non-clearance rolling block guide. The pre-load plate mechanism is used to ensure that the column does not vibrate under the action of intermittent alternating cutting force during gear hobbing. No gap in the middle roller guide structure, improve the positioning and repeated positioning accuracy of the X axis.

6, bed and column and other basic mechanism parts using a variety of advanced methods to optimize design, with high dynamic and static stiffness.

7, equipped with double worm gear double worm anti-backlash turntable, worm gear pair accuracy of DIN2 level; Full static guide rail, strong bearing capacity, good dynamic response characteristics, high motion resolution.

Search

Search