Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

Key technology

Energy feedback technique

The gear box torsion test bench can be loaded with energy feedback. The driving unit is used to drive the tested gear box, and the loading unit is used to load the tested gear box. When the loading unit is working, the energy is fed back to reduce the energy consumption of the entire system.

Arbitrary load curve loading

It can realize the dynamic loading of any load curve. The loading curve can be single form or combination form of sine wave, oblique wave, square wave, etc. Load type, load cycle, load cycle number can be set arbitrarily; And ensure the system to run for a long time, loading curve is not distorted.

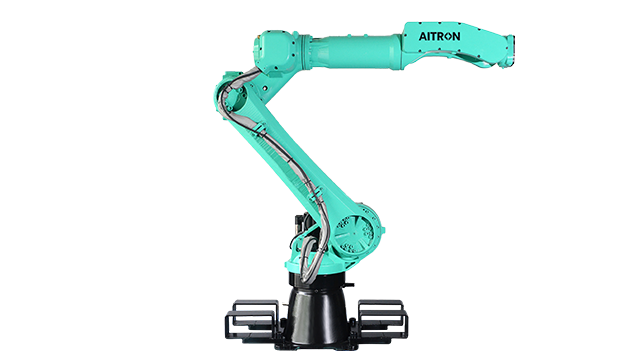

Automated control and testing

Users only set the loading curve on the operating system of the test bench and click "Start" to automatically complete the test run of the project. The automated control program makes the operation of the test bench more convenient and reliable, freeing the engineer from complex test steps.

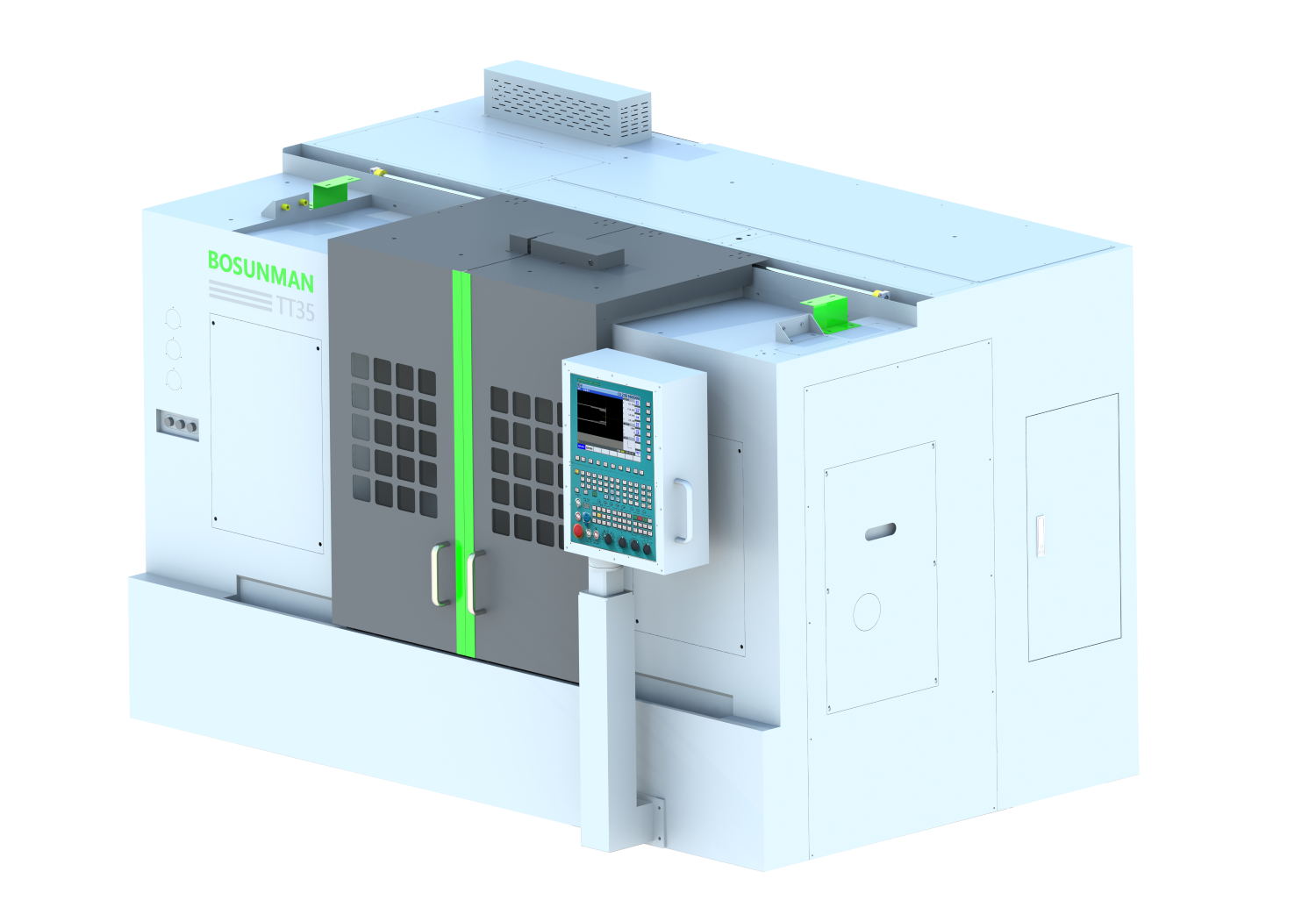

Non-standard structure design

According to different test objects and different test requirements, non-standard mechanical structure design is carried out. On the premise of meeting the reliability of the test function, the convenience and safety of the installation and use of the test bench are fully considered.

Data acquisition and recording

Through the acquisition board, the data can be collected and stored during the test process, and displayed in charts, values and other forms, which is convenient for operation and performance analysis.

Fault diagnosis technique

Through reliable signal and advanced sensing technology, the condition monitoring of the measured object is carried out in multiple dimensions. Through signal extraction and analysis, the possible fault information of the tested object can be identified and the prediction can be made in advance.

Search

Search