Post Requirements

Post Requirements

Post Requirements

Post Requirements

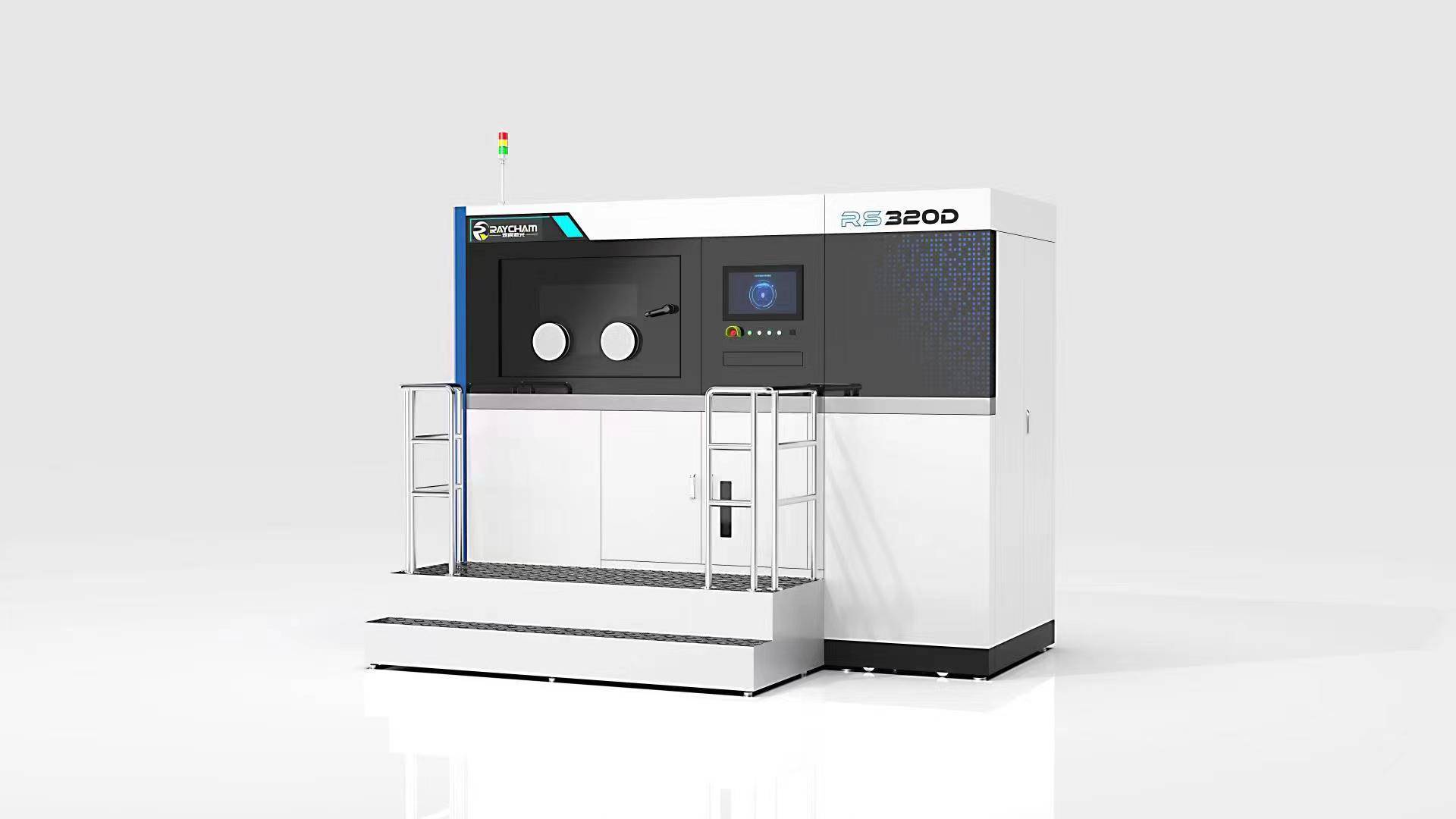

Product information

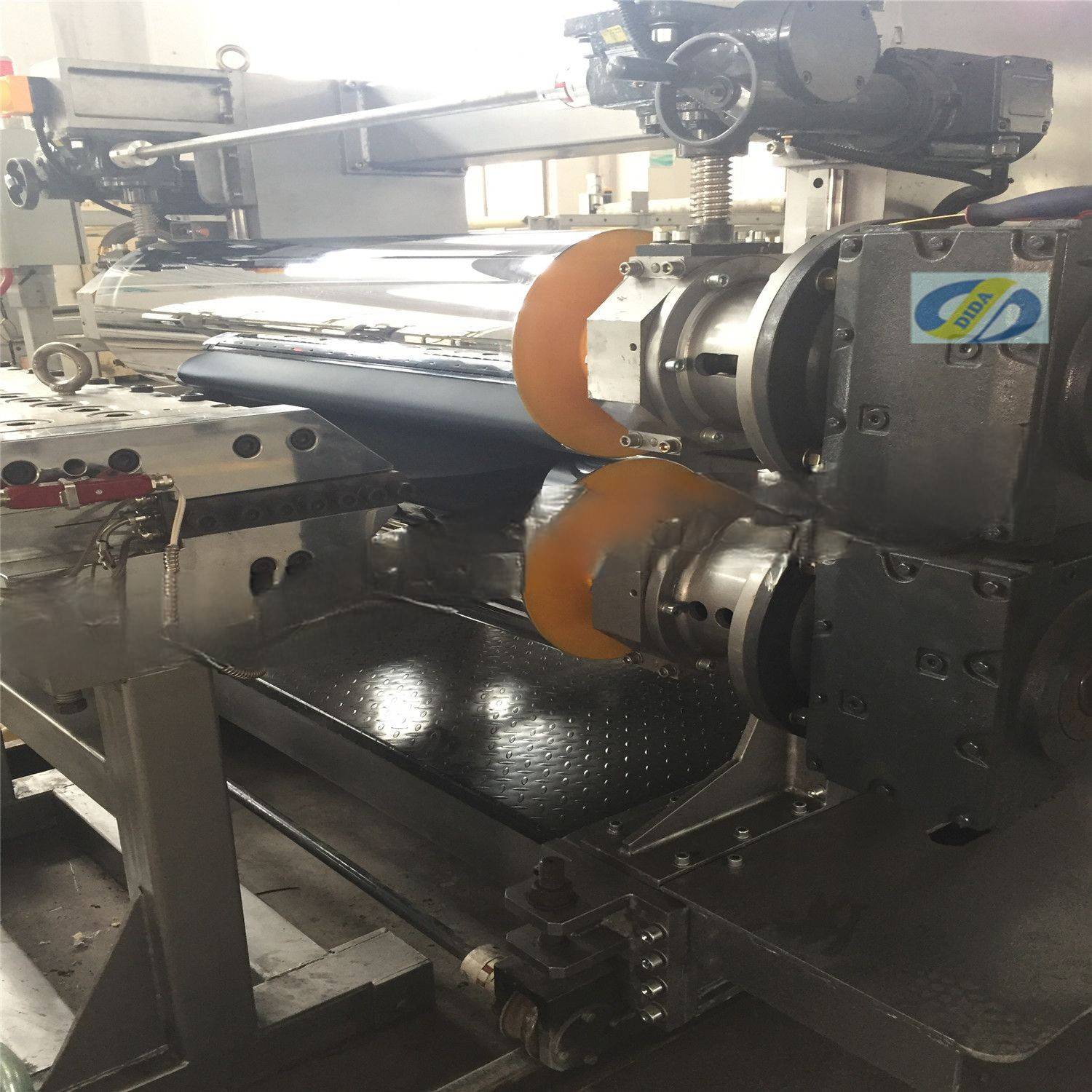

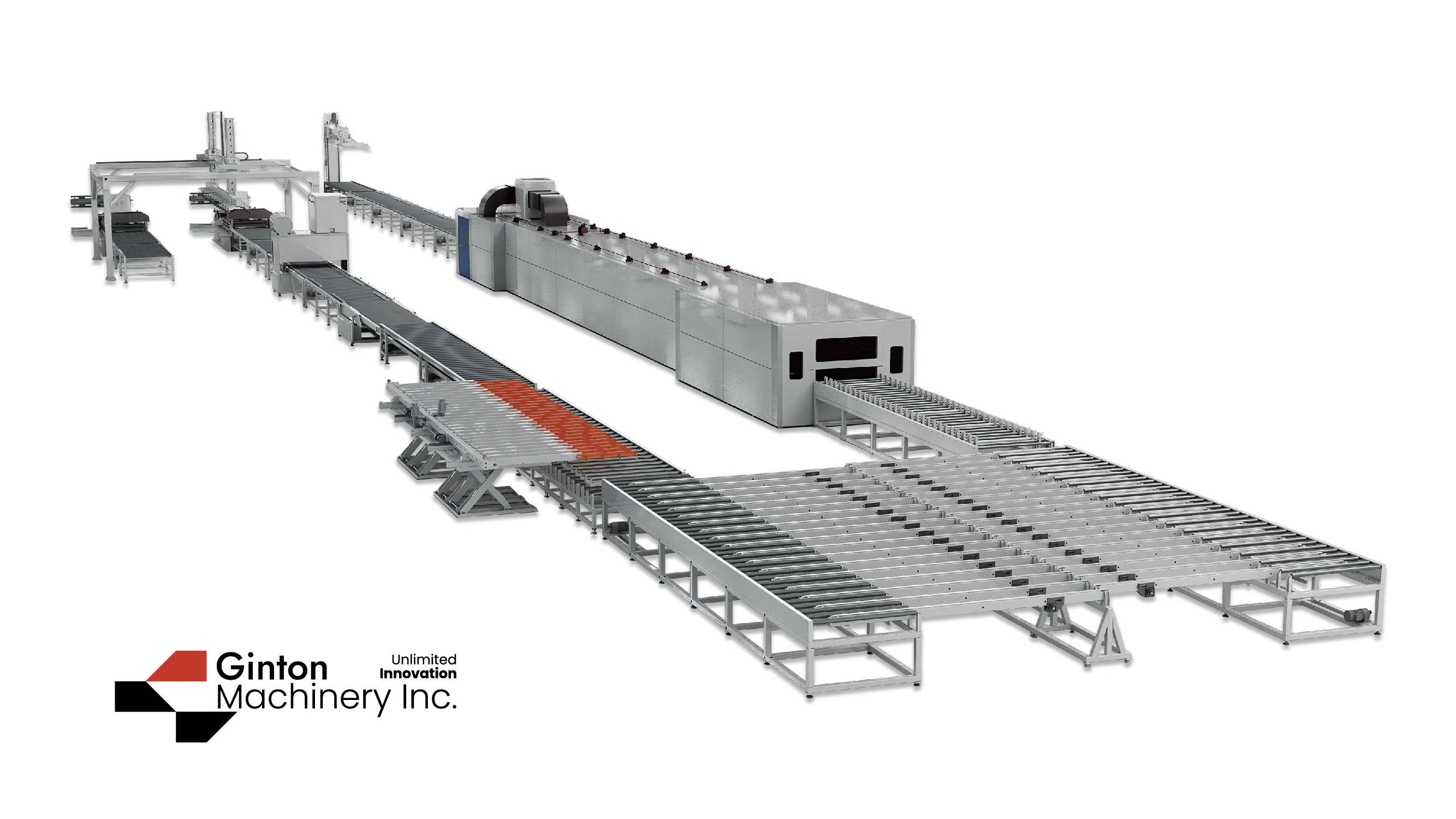

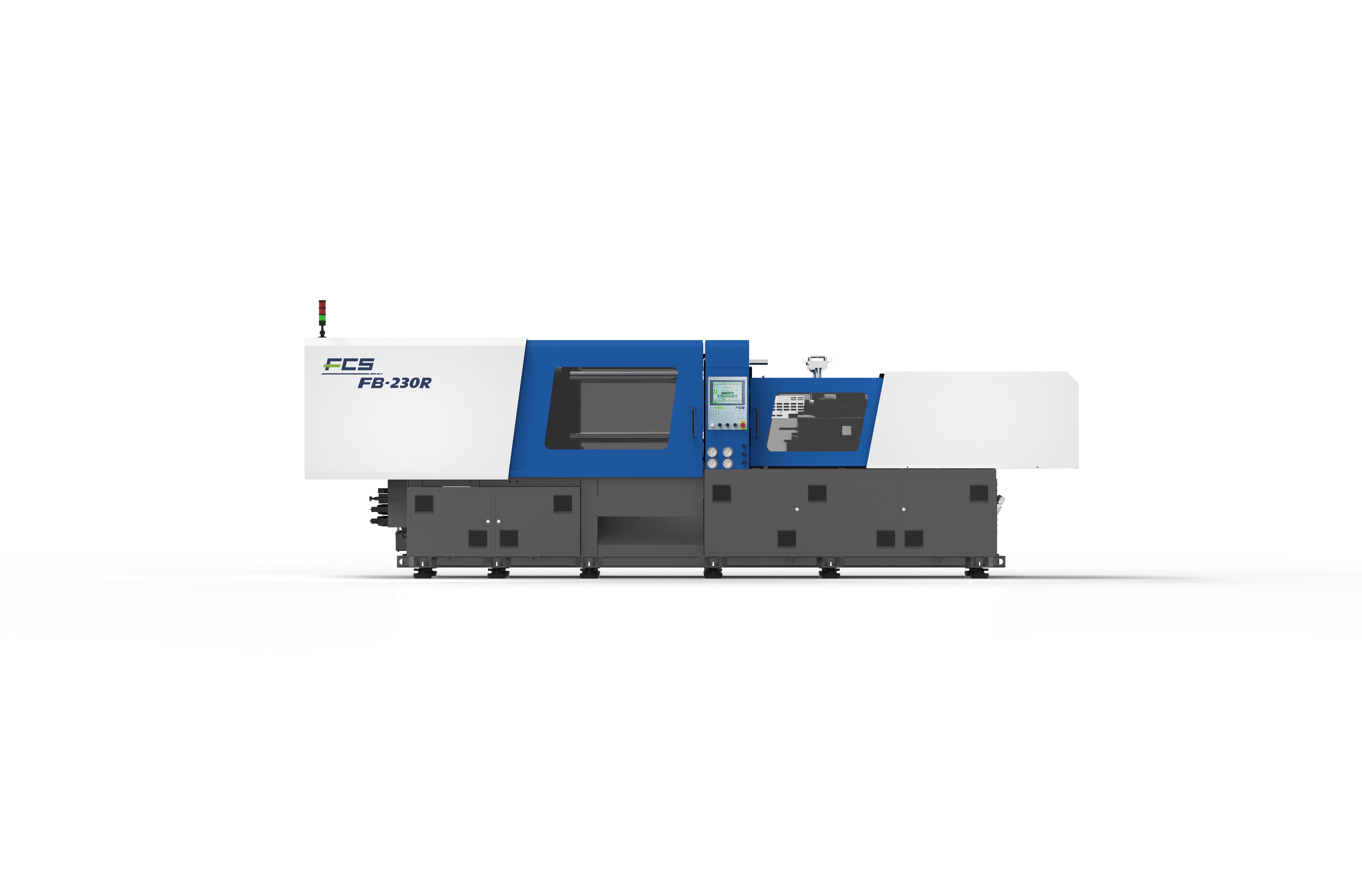

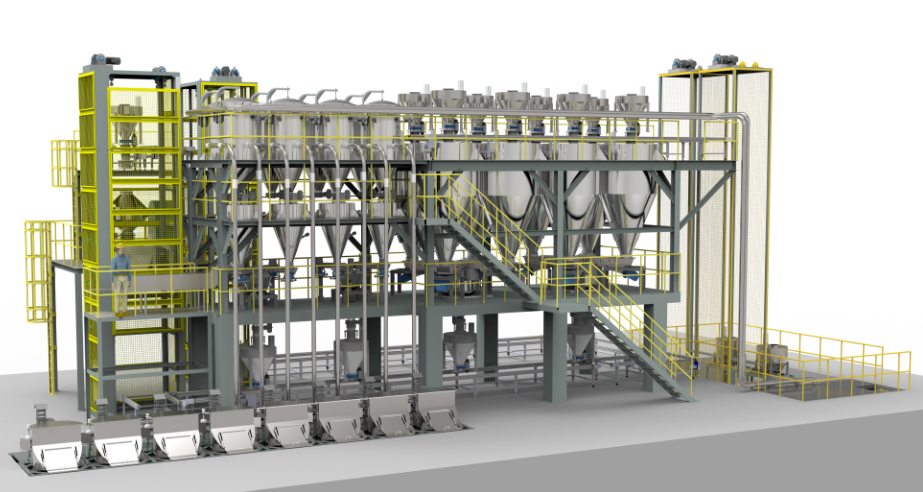

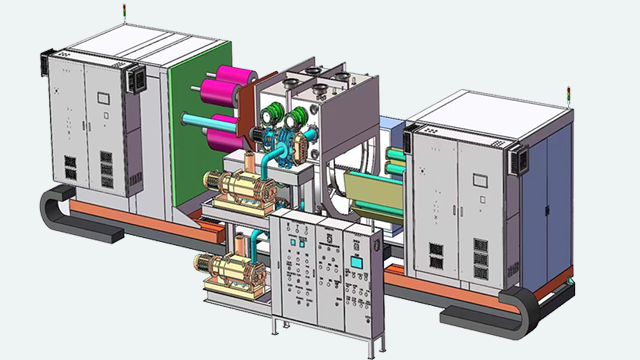

The company is committed to sheet production line, spinneret mat, polymer mattress production line, wood plastic building template production line, packaging equipment, honeycomb panel equipment, casting film equipment and various types of granulator plastic extrusion equipment research, development and manufacturing.

The company is located in Zhangjiagang, a sanitary city with beautiful scenery and beautiful scenery. The company has several experienced technicians, who can provide a series of services from product design, equipment and supporting manufacturing, installation, commissioning and personnel training according to customer requirements. Well received by the majority of customers. The company through the introduction and absorption of foreign advanced plastic machine production technology, plastic extrusion production line and widely used in the United States, Brazil, Japan, Malaysia, Poland, Russia, Australia, India, South Korea, Vietnam, Thailand, Indonesia and other regions.

We are positioned to achieve customers - committed to each customer's satisfaction and success; Our mission is entrepreneurship - to work for the benefit of our customers and to promote their realization quickly; We hope that multiple win-win - mutual understanding with customers and partners, win-win cooperation, we look forward to your patronage, and wholeheartedly serve you!

XPE is a chemical crosslinked polyethylene foam material, which is made of low density polyethylene resin plus crosslinking agent and foaming agent through high temperature continuous foaming. Compared with EPE (physically foamed polyethylene, commonly known as pearl cotton), it has higher tensile strength and smaller pores. Compared with other PE or non-PE materials, XPE material has the performance of durability, anti-light, anti-physical impact and other aspects. XPE itself is chemically stable, not easy to decompose, odorless, and has good elasticity. It is the preferred material for manufacturing crawling mat, sound insulation layer, heat insulation layer and automobile foot mat.

The foaming furnace is divided into three parts: preheating section, crosslinking section and foaming section. It is equipped with high-precision burners of brand. By heating natural gas, the temperature in the furnace can be controlled and easily adjusted. The centrifugal fan with low noise is adopted in the fan. This furnace is characterized by low energy consumption, wide production products, flexible operation and simple.

Search

Search