Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

Product Overview:

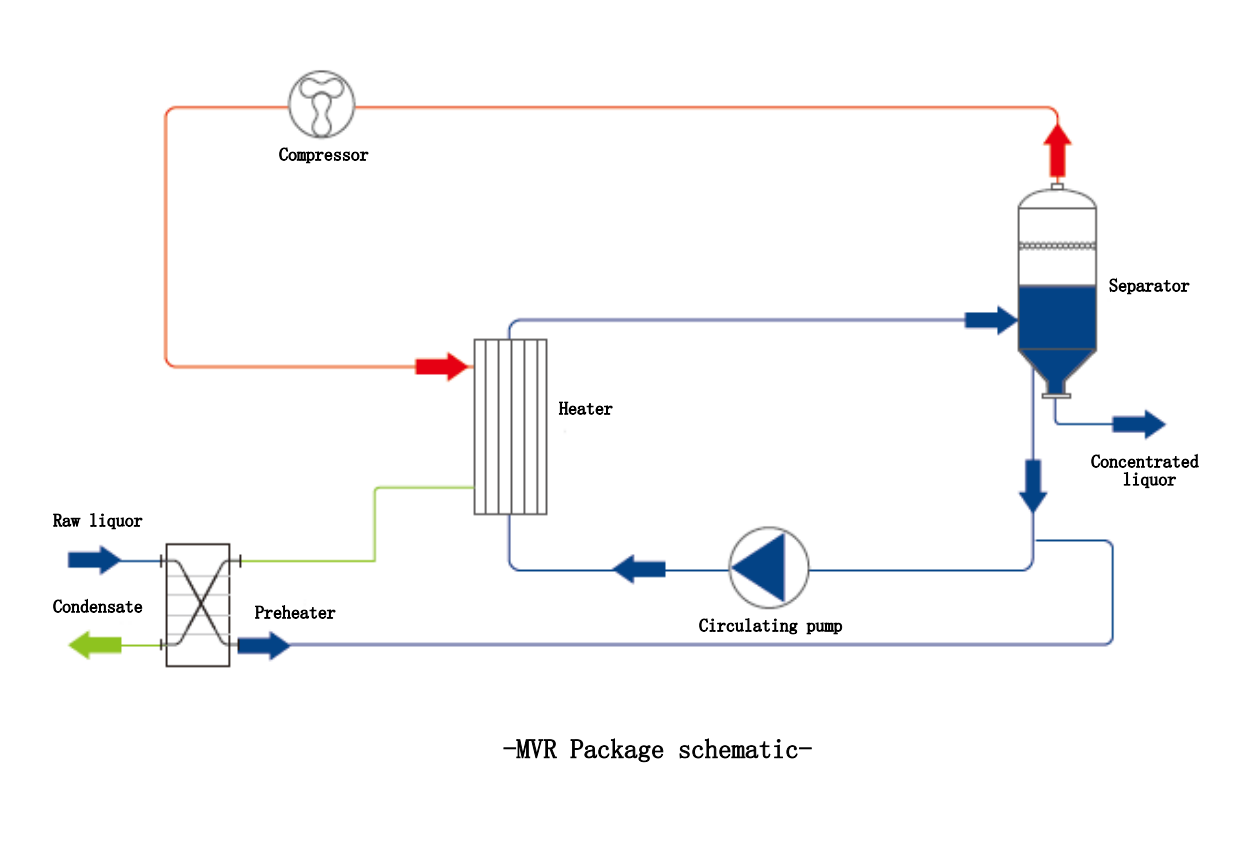

The energy consumption of MVR evaporator is mainly electric energy, and the energy saving advantage is significant. After the secondary steam compressor generated by itself is compressed and heated, the heat enthalpy is increased, and the latent heat is fully utilized as the heat source to heat the feed liquid in the system evaporator again to achieve concentration, salt removal and COD removal. In addition to the need to heat and preheat the system at the start-up stage, there is little or no need for other auxiliary heating during operation; The condensate generated after the second steam is heat exchange can also be recycled, and no other steam is discharged.

Core advantage:

- Low operating cost, low energy consumption, can save about 50%;

- Compact structure, small footprint;

- Low temperature differential evaporation, suitable for heat-sensitive materials;

- High degree of automation, smooth operation.

Application field:

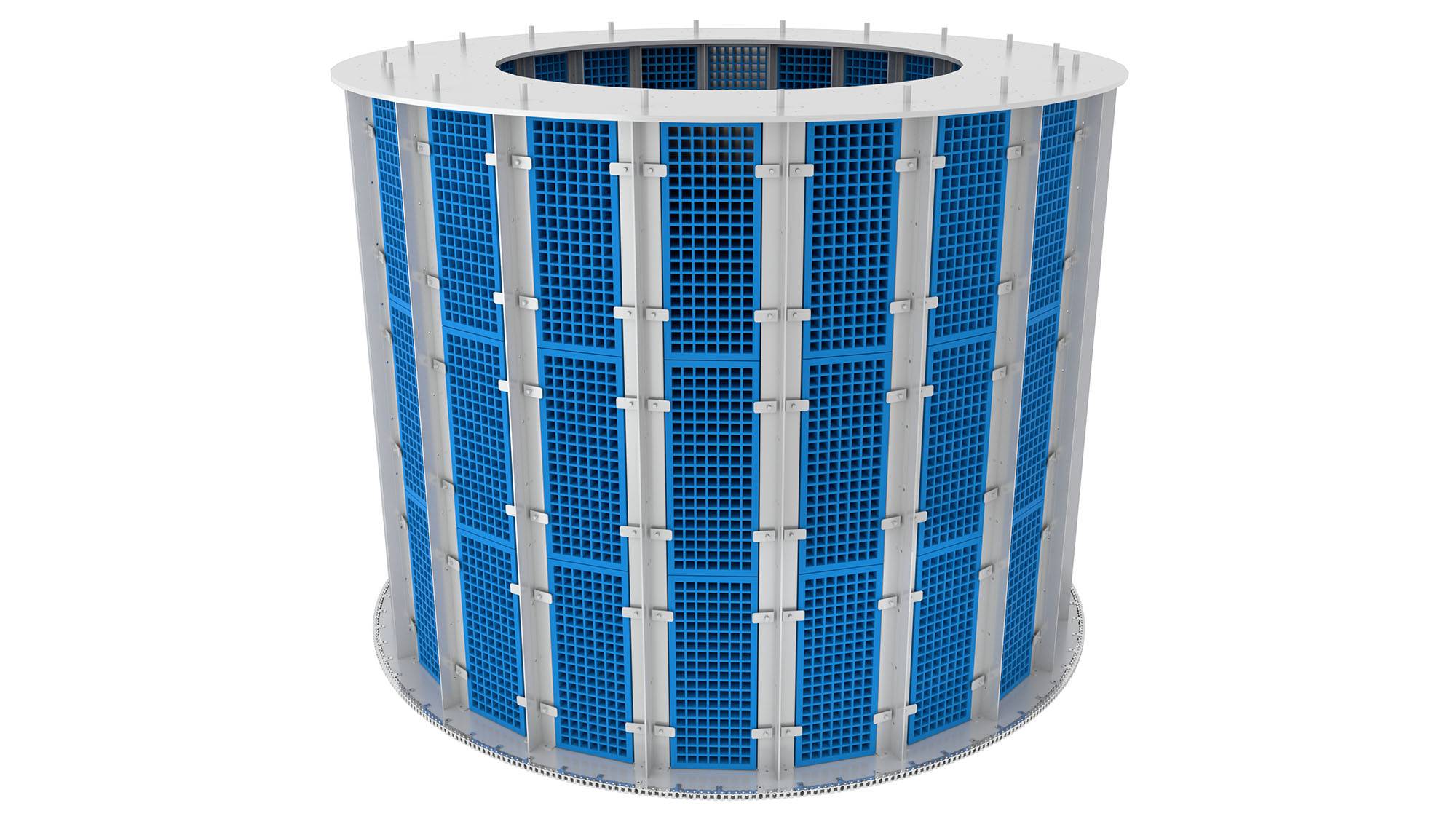

MVR evaporator can be designed falling film evaporator, forced circulation evaporator, rising film evaporator and so on.

It is suitable for evaporation, concentration and crystallization of materials in the fields of new energy industry, environmental protection industry, chemical and petrochemical industry, metallurgy industry, seawater desalination and pharmaceutical industry.

Search

Search