Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

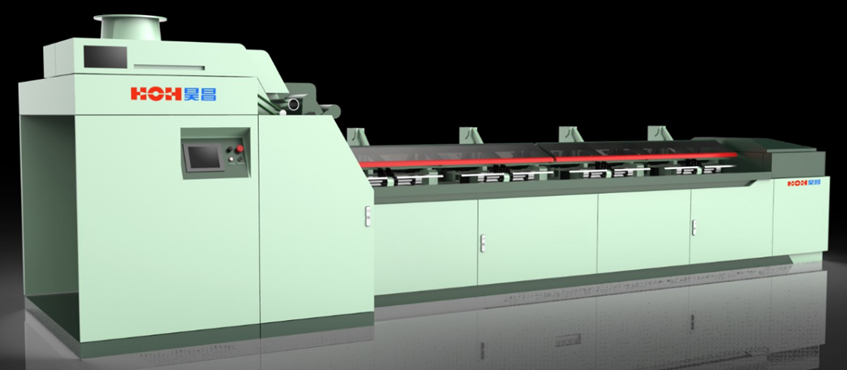

TQF-568 rotor spinning machine is a kind of new-type open end spinning machine with some features such as high speed, high efciency, automatic exhausting

impurities. It can spin directly various short fbers, 40mm cut fbers or 60mm cut viscose into single fne yarn from combed sliver.

This is a double-side-type spinning machine based on modularized design. It applies many new technologies such as air suction spinbox, semi-automatic piecing-in,

closed loop control etc. Max. rotor speed can reach 110000rpm.

Thanks to application of numerous new technologies, it holds spinning and winding quality close to full automatic rotor spinning machine, and then shows better

price-performance ratio.

VISIBLE FEATURE

Spinbox

Novel structure: change of spinning components without any tools, convenient operation.

Single step-motor drive sliver intake: enable sliver to realize variable speed feeding.

Adjustable exhausting impurities channel: reasonable adjustment according to diferent material, efcient control of exhausting impurities

percentage.

Air suction type spinning rotor: various rotors can be applied, min. rotor diameter is 32mm, max. rotor speed is 110000 rpm.

Spinning components

Permit to select diferent spinning components according to diferent technologic requirements. Wider application range and lower

operation cost thanks to series and standardization of spinning components.

T-ic intelligent convenient piecing-in system

Semi-automatic operation, intelligent control; automatically fnish piecing-in operation of yarn if only close spinbox.

Variable speed sliver feeding and reversing, millisecond-level control, perfect piecing quality of yarn.

Easy operation, higher stability and piecing-in success rate.

Winding mechanism

Package lift-of device: when the package is full or a yarn break occurs, the package will be lifted immediately and departed from winding

roller.

New type tapered winding form: Winding roller for tapered package is divided into left and right part on which the speeds can be

automatically adjusted, thus enable tapered package to realize double-support winding.

Novel bobbin cradle structure: This structure can ensure yarn tension uniform inside and outside take-up package; permit to spin yarn

continually when dofng and to reserve the tailing formation.

Electronic yarn clearer

A standard terminal is reserved on the control system of machine; various electronic yarn clearers can be installed at any moment.

More fexible spinning functions

Equipped with the function for spinning fancy yarns and two diferent kinds of yarns can be spin at same time on two sides of the machine,

which makes it more fexible so as to have a better use of space.

Electrical control system on machine body

Novel electrical control system on machine body:

So easy operation and maintenance, faster communication, stronger anti-interference.

Electrical cabinet design with patent

More reasonable layout for electrical components, more convenient operation and maintenance, with a

circulation ventilation system for fast cooling inverter and getting longer life of inverter.

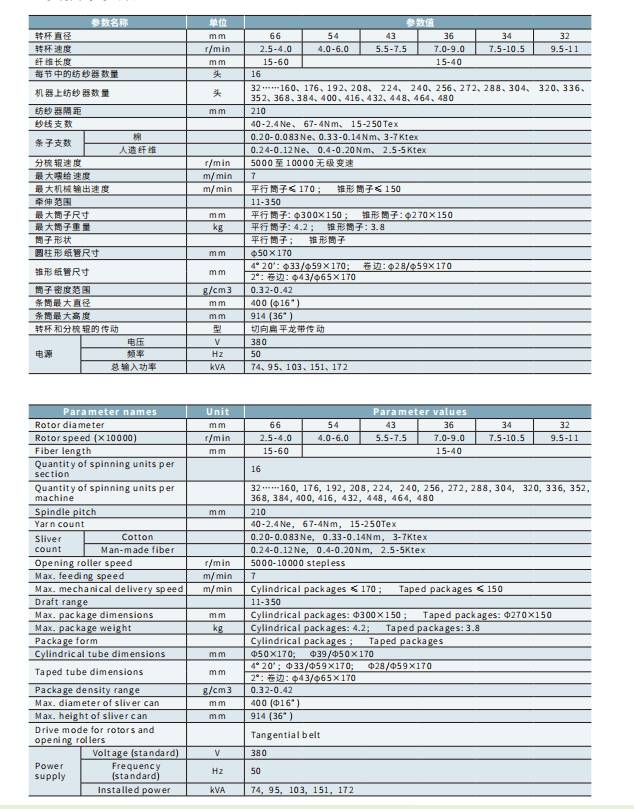

MAIN TECHNICAL PARAMETERS

Search

Search