Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

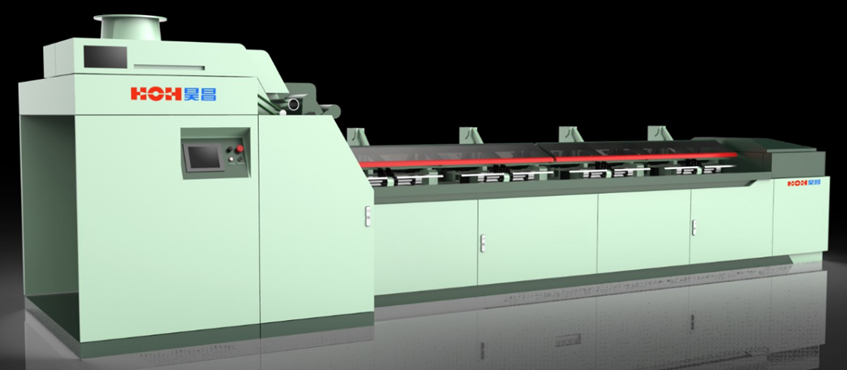

TT-868 rapier loom is a new generation one developed by our company based on existing textile demand, with many years of R&D and production experience. This

machine with compact structure adopts direct drive motor as the main motor, electronic pick-finding, weft insertion controlled by variable pitch propeller type rapier

drive system, and optimized shed geometry. With some features such as short transmission, easy to operate, energy saving and low maintenance cost, as well as no

drive belt and electromagnetic clutch are required.

The width range of this machine is 170-380 cm. It is suitable for weaving medium and thin fabrics, especially for weaving silk, silk-like and jacquard fabrics.

VISIBLE FEATURE

Main drive

The main drive is based on a direct drive switched reluctance motor which is with high starting torque and oil cooling system. There is no drive belt and

electromagnetic clutch, which reduces maintenance workload and saves energy.

The loom speed can be easily set on the HMI touch-screen and automatically varied according to different strength of the wefts

Weft Insertion Drive

The weft insertion drive system combined with the connecting rod mechanism and the propeller mechanism reduces the acceleration of weft insertion,

even if the low strength yarn can be easily woven too. Because there is no gear drive, the noise is minimized.

Weft Insertion and Shuttle Path

SK Weft Transfer System: Utilize short and light gripper for weft insertion, minimizing the shed and reducing the draft of the warp yarns, so as to get higher

weaving speed.

FPA Weft Transfer System: Offer a race board with no guide hooks in the shed, which reduces the damage for the warp yarns, optimize the design of the

rapier gripper so as to clamp more different weft yarns. All can be got the better solution for single yarn, double yarns or fancy yarn.

Pick-finding

The pick-finding is achieved depended on the bridge gear driven by an independent motor and the slow motion of main motor controlled by a

microcomputer. The levelling angle of the heald frames can be set on HMI touch-screen, with no mechanical adjustment, and the structure is simple and

stable.

Electronic Warp Let-off and Fabric Take-up

The electronic warp let-off and fabric take-up are respectively driven by independent servo motors, with a simple and compact

structure. Their operation is controlled by the CPU, ensuring stable warp tension throughout the weaving process and effectively

reducing starting marks.

Electronic Weft Selector, Weft Cutter and Leno Device

Step-motor-type weft selector controlled by Microcomputer can minimize the extra tension on the weft yarns, and operate reliably without maintenance.

Multiple choice of weft cutters: mechanical weft cutter, rotary weft cutter, servo-motor-type weft cutter.

The electronic leno device is driven by an independent motor.

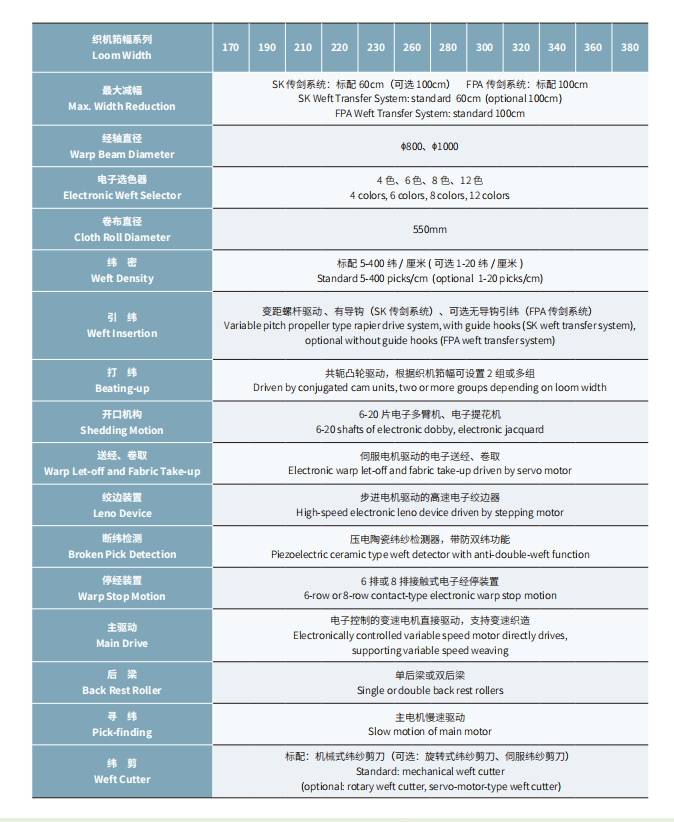

MAIN TECHNICAL PARAMETERS

Search

Search