Post Requirements

Post Requirements

Post Requirements

Post Requirements

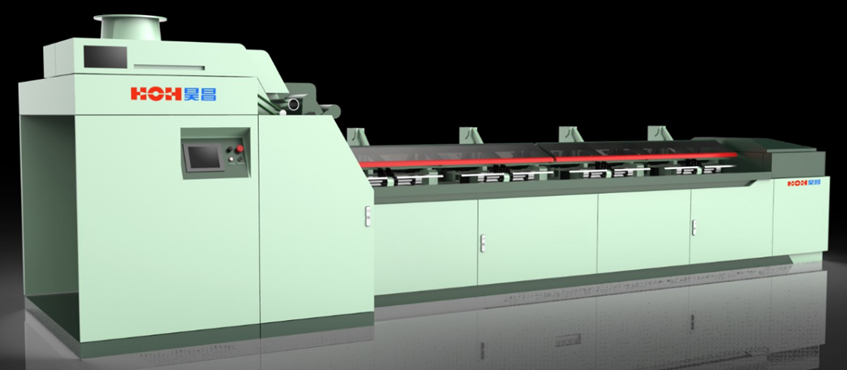

Product information

Applied range

Cotton yarn, wool yarn, polyester yarn, acrylic yarn, yarn with spandex, sewing thread and other blended yarn.

◎ Energy saving, the use of spindles of the same size per ton of yarn electricity is lower than any twisting equipment.

◎ The machine uses advanced electronic digital control system with electronic yarn guide and forming function.Yarn package forming, yarn twist and spindle speed

can be set on the display. Take- -up and traverse motion are independently driven by servo motor. Easy operation and powerful functions.

◎ Synchronization protection function for interruption of power supply and PLC guides three separate motors to run at an invariable speed ratio so as to ensure same

yarn twist during starting and stopping machine.

◎ Compact structure design, small occupied space, diferent spindle specifcations (126, 136, 146, 156 mm and heightening spindle pot) for choice.

◎ Take-up tension can be adjusted at will, so the soft dye package can be directly produced.

◎ Gentle locating of spindle pot, lower vibration, load supporting structure of bearing-end on spindle blade and lower maintenance thanks to high quality spindle

with perfect structure.

◎ Lower installation position of spindle, longer efcient twist area and smaller yarn balloon ensure lower twisting tension, even twist and lower strength reduction of

yarn.

◎ Spindle with swiveling support, which can adjust the contacting pressure between spindles and tangential belt, is easy for operation.

VISIBLE FEATURE

Human machine interface

Spindle speed, twist, twist direction, forming and other process parameters can beset in the touch screen with encryption management, which is easy for operation.

Yarn traverse guide mechanism driven by servo motor

The speed and contrail of traverse Yarn-guide mechanism can be set at will according to production requirements so as to get perfect fnished packages. No oiling for the self-lubricate orbits without pollution.

Take-up and overfeed motion driven by servo motor

Take-up and overfeed motion is driven by servo motor and controlled electronically, which can be set the winding speed at will in the designing range.

The overfeed ratio can be adjusted by overfeed change gear and yarn defection roll so as to get diferent density packages.

Spindles

High spindle speed, light running load and low maintenance cost thanks to perfect spindle structure, the load support structure through the bearing end surface of spindle can efciently avoid replacing the whole spindle because of the damage of spindle pivot.

Capsule or steel ball tensioner ensures machine to get a wide twist range. The spindle pot , which is made of aluminum alloy or stainless steel, can be heightened to 230mm. Depending on some special requirements, various kinds of energy- -saving spindles can

be selected by customers.

Package cradle

The pressure slowdown mechanism for package cradle, which is made of aluminum alloy, can get even density of yarn package structure so that it can be used to directly produce dyeing yarn.

Spindle with swiveling support

Spindle with swiveling support can Automatically adjust the contacting pressure between spindles and tangential belt, which obtains uniform spindle speed and saves energy. (Optional handle lever for more convenient operation)

MAIN TECHNICAL PARAMETERS

Search

Search