Post Requirements

Post Requirements

Post Requirements

Post Requirements

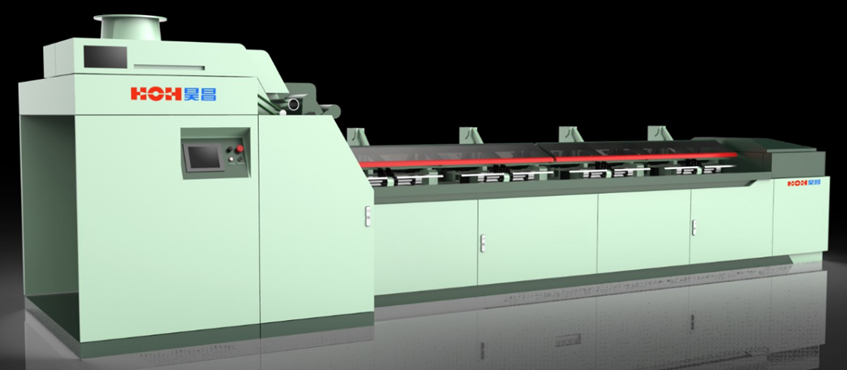

Product information

Increased number of plucking knives for finer plucking.

The beater is driven by double-motors independently to meet a production of 2000kg/h.

Enlarged distance between beaters reduces the interaction of air current produced by beater when rotating in high speed, makes smooth transfer of cotton.

Cotton compressing roller is welded by star-shape steel disc and driven by chain motor to track tower motion, favorable of cotton tuft plucking.

Profile of suction chamber is optimized, favorable of air suction volume even distribution and increasing tuft transfer efficiency.

Enlarged suction slot area realizes high efficiency of cotton transportation.

Flexible action, reliable precision, high automation and intellectualization,ensure convenient integrated control of blow-carding system.

Grid height adjustment function.

Meet the technological requirement of two lines / three types of material in a single machine.

Specifications:

Search

Search