Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

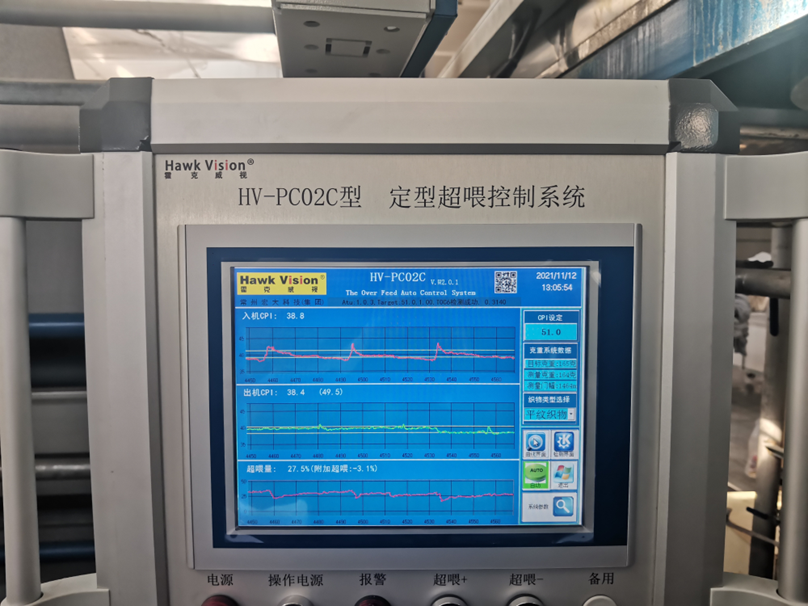

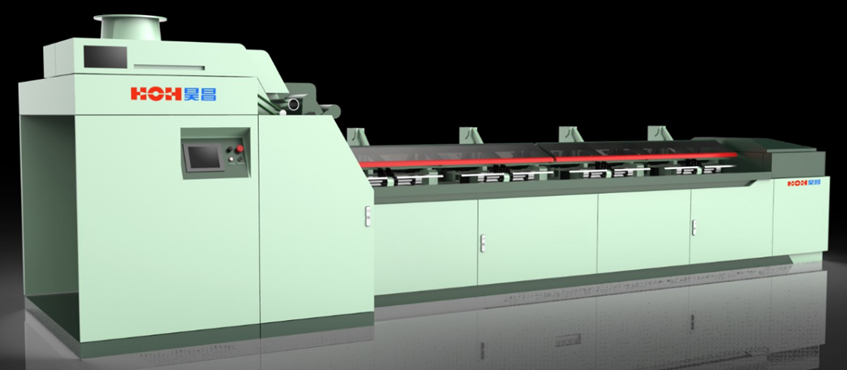

Hawk Vision® Automatic Overfeed Control System for Density Detection

Hawk Vision® Stenter’s Overfeed Automatic Control System

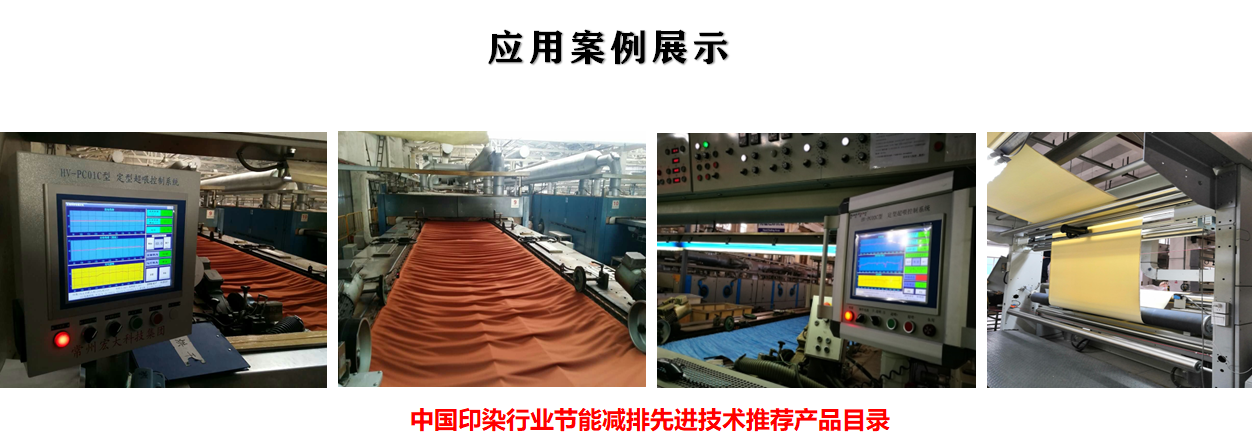

The twelfth batch of recommended catalog products for advanced technologies for energy conservation and emission reduction in China's printing and dyeing industry

systematically introduced

Adopt internationally leading digital image processing, pattern recognition and information fusion technologies, and use industrial cameras as detection elements to comprehensively detect the weft density of cloth in motion in real time, and adjust the weft density of fabric in real time according to the weft density detection results., the weft density reaches an ideal state and provides guarantee for the realization of high-quality textiles. This system overcomes the shortcomings of photoelectric overfeed and ordinary image automatic overfeed systems, and is a new generation of high-precision automatic overfeed control systems. This product technology has the national invention rights.

system function

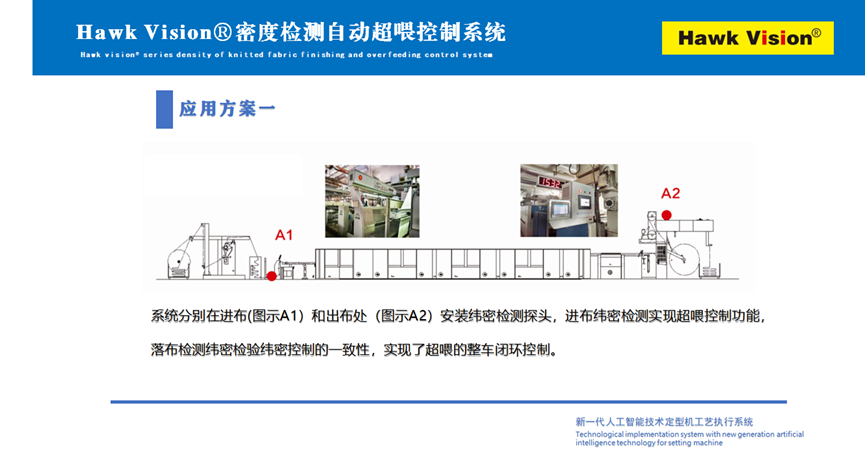

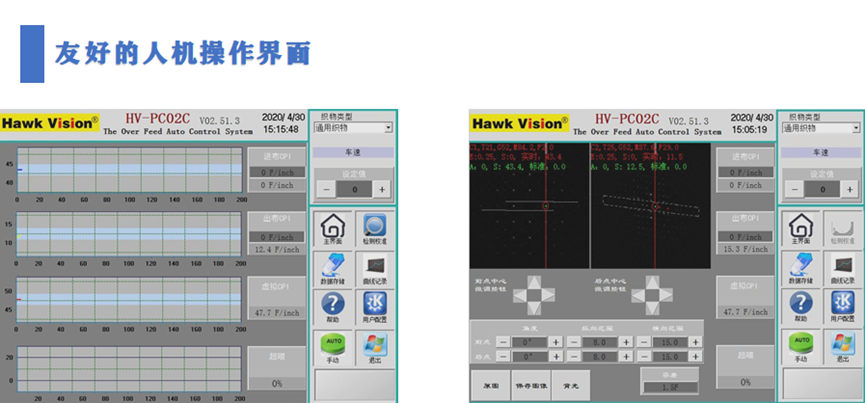

◇ The system uses two sets of online weft density detection sensors for cloth inlet and cloth outlet to form a closed-loop detection and control system;

◇ Adopt special light source design to meet the precise measurement of weft density of fabrics of various colors and weave structures, and have a wide range of application;

◇ The system can detect the fabric weft density value online in real time and output adjustment control signals to control the overfeed amount of the overfeed motor;

◇ Ensure the uniformity and consistency of fabric weft density during the production process, effectively solve the difference between head and tail weft density, and improve product quality;

◇ It has a friendly man-machine interface dialogue function, which can display test results in real time, making it easy to operate;

◇ With database management functions, users can control and manage production quality.

system value

- Improve product quality and reduce quality complaints;

- Reduce manual labor intensity and avoid mistakes; strictly detect and control vehicle speeds to reduce energy consumption and production costs;

- Reduce requirements for operator skills and experience;

- Enhance product competitiveness and company brand image.

| product specifications | technical parameters |

Adapt to vehicle speed | 0~80m/min |

detection range | 8 - 200 roots (circles)/cm or 20 - 500 roots (circles)/in |

Image measurement accuracy | 0.05mmm |

detection time | Less than 100ms |

working methods | continuous |

Search

Search