Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

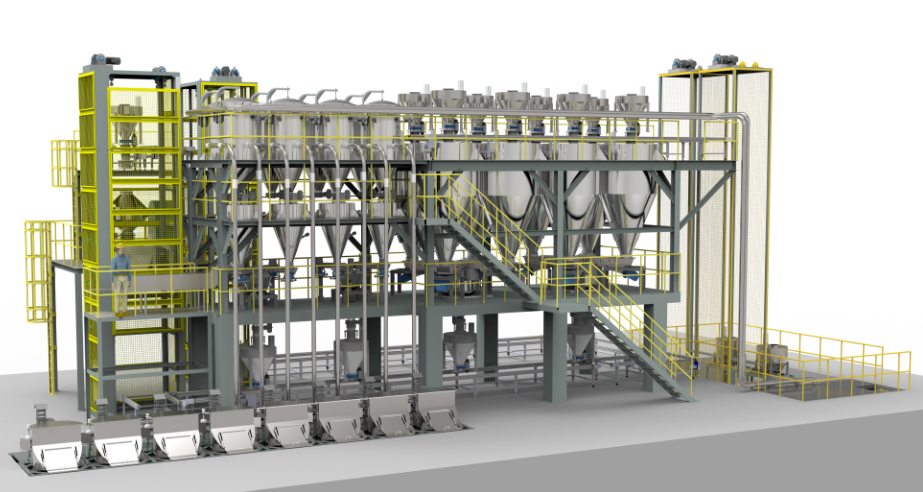

Due to the characteristics of the wood-based panel continuous flat pressing hot pressing production process and equipment process, the key equipment steel belt that affects the product quality will adhere to materials, glue spots and glue (especially when using MDI glue production) in the production process, resulting in a decline in the surface finish and appearance quality of the product. At the same time, the decrease in heat transfer speed will lead to a decrease in output, which directly affects the profitability of such production lines!

Because the material adhering to the steel belt has experienced high temperature hot pressing, the adhesion is very strong and it is not easy to remove. And the steel belt is the key equipment to determine the quality of the product, the thickness, strength, flexibility, thermal conductivity and other performance requirements are extremely high, can not be used to scrape with hard objects, can not use more than 500 degrees of high temperature heating to burn the adhesive, can not use a sudden cooling to remove the adhesive, that is, the use of soft sand belt in the same position to implement a long time grinding, It will also lead to the thinning of the steel belt, resulting in a large area of product quality decline and a large number of losses. Because of these harsh conditions, how to ensure the cleanliness of the steel belt has become the key bottleneck of how to improve the efficiency of the wood-based panel continuous flat pressing production line!

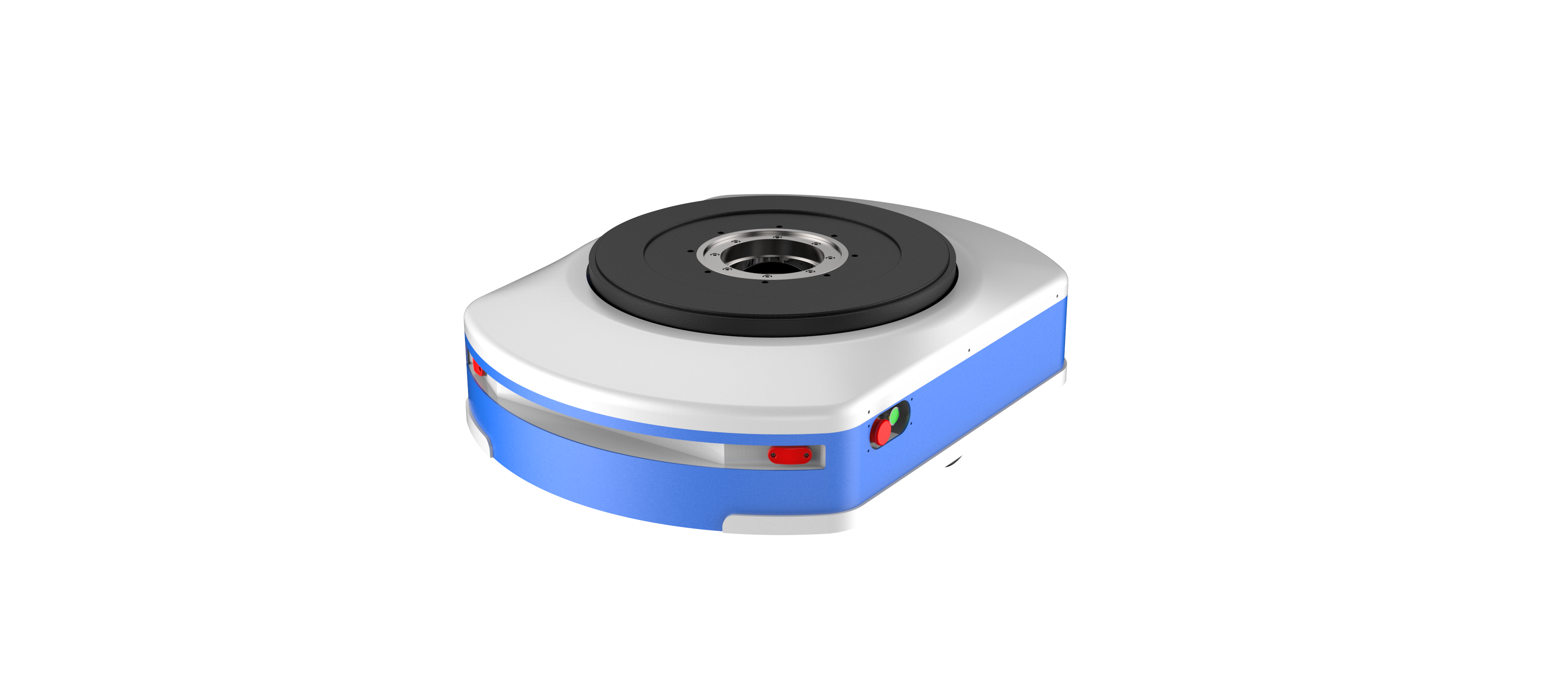

Combined with the above characteristics, through long-term exploration and practice, our company has developed a set of automatic, real-time, online, mobile steel strip cleaning brush equipment, equipped with a complete set of control systems such as accurate position closed-loop control, accurate pressure closed-loop control, accurate cleaning plan and time control and friendly human-machine interface, which can safely, efficiently and automatically clean the steel belt!

Search

Search