Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

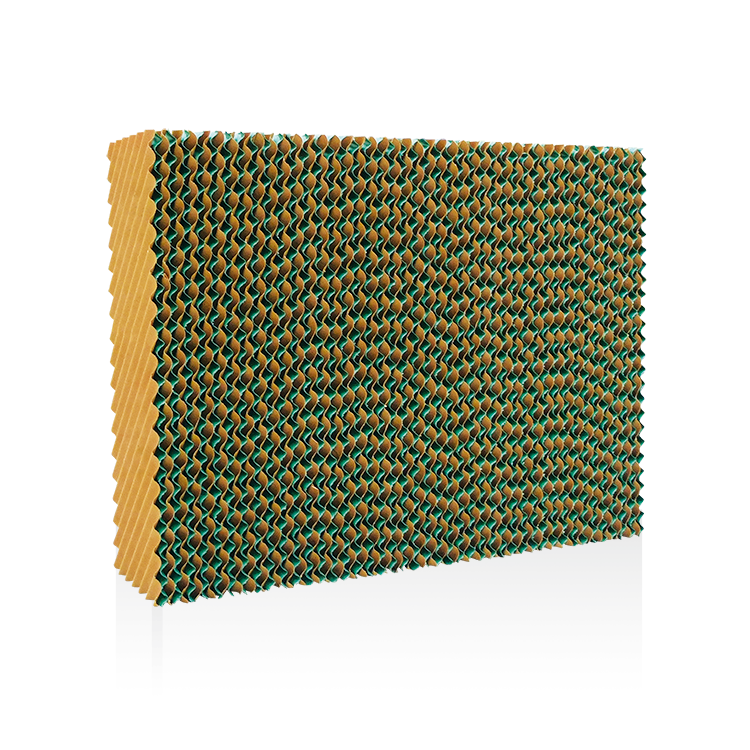

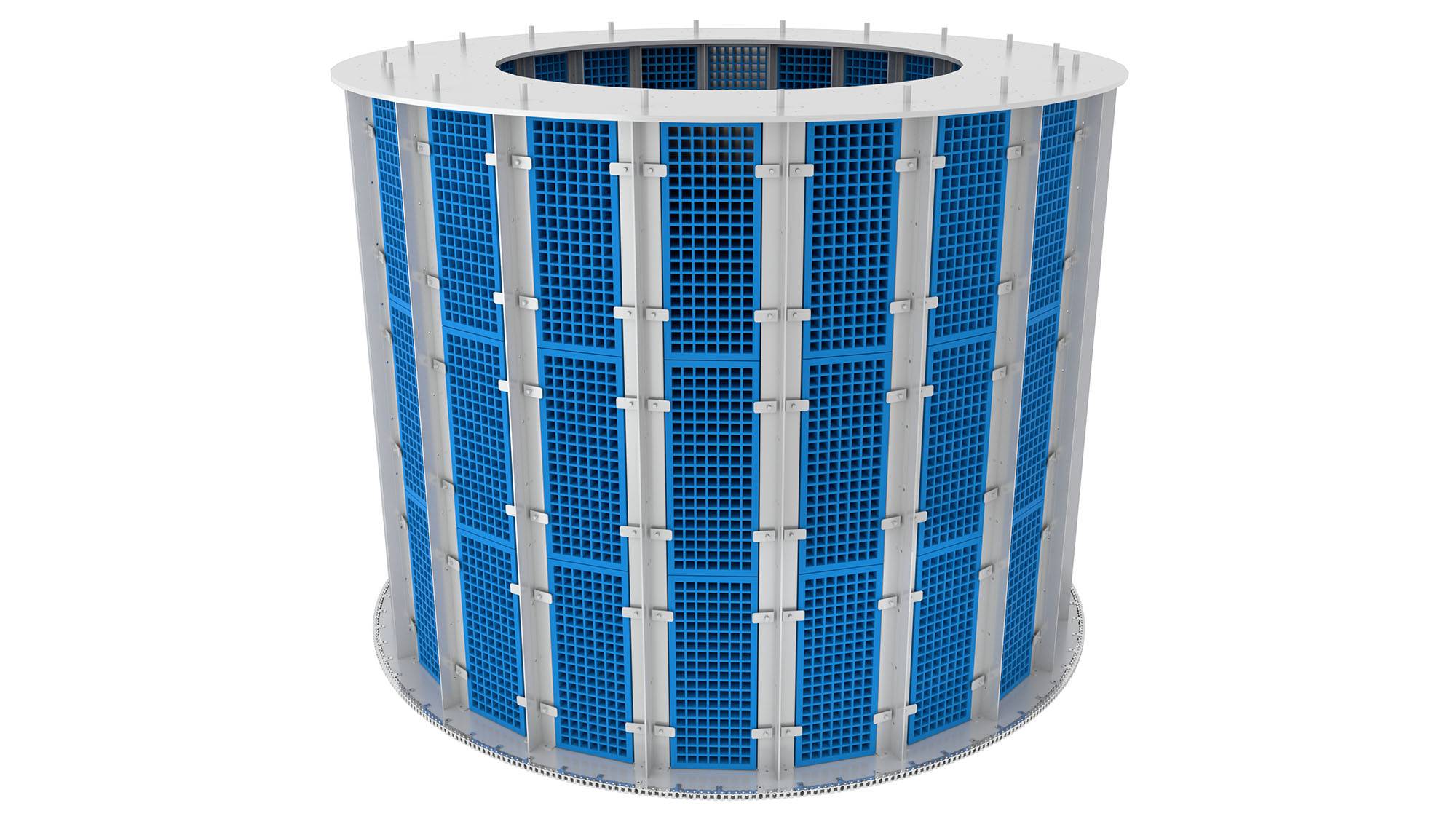

Due to the characteristics of wood-based panel hot press production process and equipment process, it is determined that the 200-degree high temperature gas discharged by the press is rich in toxic, harmful and highly flammable organic matter such as free formaldehyde, vaporized lubricating oil, wood dust, fiber, paraffin, ethanol, phenol, water vapor, and particulate matter. Our specially designed suction system with adjustable duckmouth ensures that before the exhaust gas does not spread, the high temperature, toxic and harmful substances generated during the hot pressing process are collected, and after special treatment, avoid the inner wall of the outer cover or suction pipe to condense and adhere to a large number of wood dust, fiber, paraffin and other highly flammable substances in the exhaust gas. Prevent the air extraction pipe from sticking and blocking, prevent the suction effect from decreasing and causing the press to catch fire, prevent harmful gases from spreading and damaging the health of employees, and prevent the release into the atmosphere and causing environmental pollution. After using the gas wet treatment system of the press, there is no need to clean the suction pipe of the press (the current solution provided by a large number of manufacturers, like the range hood in the kitchen, It must be cleaned regularly) to improve the equipment opening probability, protect the steel belt (a fire damage to the steel belt and the loss of more than the entire system investment), reduce the safety risk caused by cleaning blocked pipelines (to avoid accidental fire and casualties during cleaning).

Our specially designed nozzle evenly mixes the special liquid with the gas to form a foam, which is sprayed into the air pipe near the suction port, so that the air pipe is filled with bubbles at any time. The gas bubble reduces the temperature of the press gas, and sends the toxic, harmful and flammable substances in the gas, such as free formaldehyde, vaporized lubricating oil, wood dust, fiber, paraffin, ethanol, phenol, water steam, and particulate matter into the special gas/liquid cyclone separator, and exhausts the clean and cooled steam through the chimney. After the other impurities are settled through the settling tank with the liquid, the solid matter is scraped out by the silt automatic scraper to be used as fuel for the energy plant, and the water is filtered and recycled. This ensures that the suction system maintains a long time, efficient and stable suction effect, prevents the fire of the press due to the adhesion of the air duct, and prevents possible deformation and loss of the steel belt!

Benefits of the solution:

1. Realize maintenance-free and maintenance-free suction duct to improve opening probability;

2. Ensure the cleanliness of the press to the maximum extent and reduce the fire risk of the press.

3. Efficiently and cleanly handle the exhaust gas pumped out, providing a comfortable environment for operators and visitors.

4. Efficient recycling of resources, simple operation, energy saving and environmental protection, no pollutant emission;

Scope of application:

Continuous press, paint room (furniture painting, car painting) and similar conditions of the room exhaust gas, waste incineration gas treatment!

Search

Search