Post Requirements

Post Requirements

Post Requirements

Post Requirements

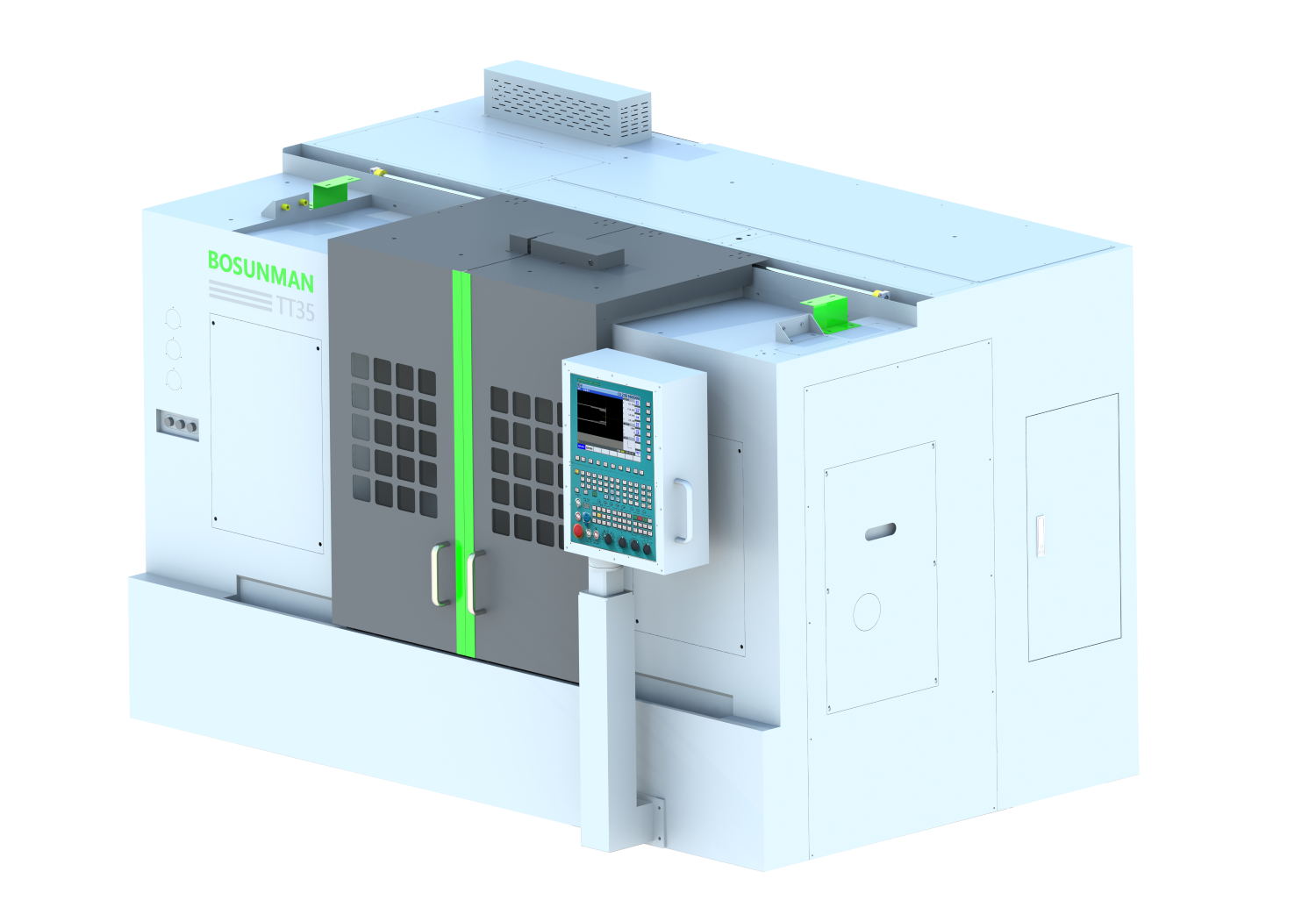

Product information

Main features of the product:

There is a large depth of cut, the grinding wheel can cut up to several millimetres at a time;

Slow feed speed, due to the large grinding depth, grinding force and grinding heat are very large, limiting the feed speed of the workpiece, the general longitudinal feed speed of 30 to 2000mm/min;

High-pressure cooling water flushing system, due to grinding cutting depth is large, the grinding wheel at the same time work more abrasive particles, generate a lot of heat, will make the surface of the workpiece burns, so the coolant should have a certain pressure and flow into the grinding area, play a forced cooling effect, the heat generated by the rapid take away, and at the same time flushing out attached to the surface of the wheel part of the filamentous abrasive debris.

A variety of forming and dressing technology, diamond roller dressing, diamond pen or diamond disc through the X, Y two-axis linkage dressing grinding wheel, dressing forming high precision;

C3 precision ball screw, high precision linear slide rail, high forming precision, good surface quality;

High strength machine body, professional manual scraping technology;

High production efficiency, fast workpiece forming, can be directly processed from blank to finished product without pre-processing, simplifying the process, saving man-hours and reducing costs;

Automatic grinding cycle can be realised;

The machine tool has novel modelling, implements mandatory safety standards, and the design of the fully enclosed cover meets the requirements of environmental protection.

The above pictures are for reference, subject to the real thing.

Main working accuracy of machine tool

Standard specimen 45# steel tempering; 50 * 50 cylindrical material (five pieces) the entire worktable surface arbitrarily placed.

Processing surface parallelism of its base: ≤ 300:0.003mm

Workpiece surface finish: ≤ Ra0.4um

Positioning accuracy: ≤0.001mm

Front main unit and rear main unit

The front base and rear base adopt the mature and stable half-waisted T-type splicing structure, which has high overall rigidity and anti-vibration performance, and can meet the requirements of high-precision equipment on the basic parts and the overall cutting force of strong cutting.

Working table

The table adopts roller linear guide and screw motor direct connection with reducer, the left and right reciprocating motion speed of the table adopts the new generation system control, which can adjust the left and right running speed according to the actual use situation, not only the motion is smooth and reliable, but also has better stability in the face of strong cutting.

Column and sliding frame

The rear main frame supports the sliding frame for full-stroke movement, and the guide rails adopt roller linear guide rails, which have good rigidity, positioning accuracy and wear resistance. The movement power adopts AC servo motor to directly drive the ball screw to control the forward and backward movement of the sliding frame.

Grinding head set and upper frame

The spindle and 15.8KW motor are directly connected by coupling, which has enough grinding power and grinding precision.

The feed system of the grinding head group adopts AC servo motor with built-in encoder with brake to drive the ball screw directly through the device to control the feed movement of the grinding head group.

The direct connection between the headstock and the upper frame is made by means of a linear guide ball screw and a servo (with brake) motor, which greatly reduces the start-up friction coefficient and improves the transmission precision and safety reliability.

Machine Lubrication

Independent automatic circulation lubrication system provides frequent clean lubrication for guide rail and screw. And has a loss of pressure alarm function.

6、 Machine protection

This model is equipped with a sealing cover for the working area, which effectively prevents the grinding liquid from spilling out of the machine and minimises the impact of dust and mist on the environment, ensuring a clean environment and the health of the operators.

7、 Electrical system

The machine adopts Taiwan New Generation 6M CNC system. The system comes with suspended hand-cranked pulse generator. The machine adopts independent electrical cabinet, equipped with three-colour alarm light. Adopting centralised operation control panel, all the operation components and CNC system are concentrated here.

8、 Cooling system

The hydraulic system is equipped with a high-flow air cooling system, the cleaning flush water tank is equipped with a magnetic separation filtration device and a complete set of cooling system, and the electrical operation box is equipped with a forced cooling device, which is able to meet the needs of high-efficiency grinding production continuity, and further ensure the grinding quality.

The main configuration of the machine tool:

Three-axis servo control

Centralised powerful cooling water tank with magnetic separator

Centralised lubrication system

Standard accessories

Work area guards with Plexiglas viewing windows

Taiwan New Generation 6M CNC with hand pulse generator

Independent power hydraulic station with air cooler

(8) Electromagnetic suction cups (according to the processing needs of the configuration)

(9) Electrical operation box with forced cooling device

Search

Search