Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

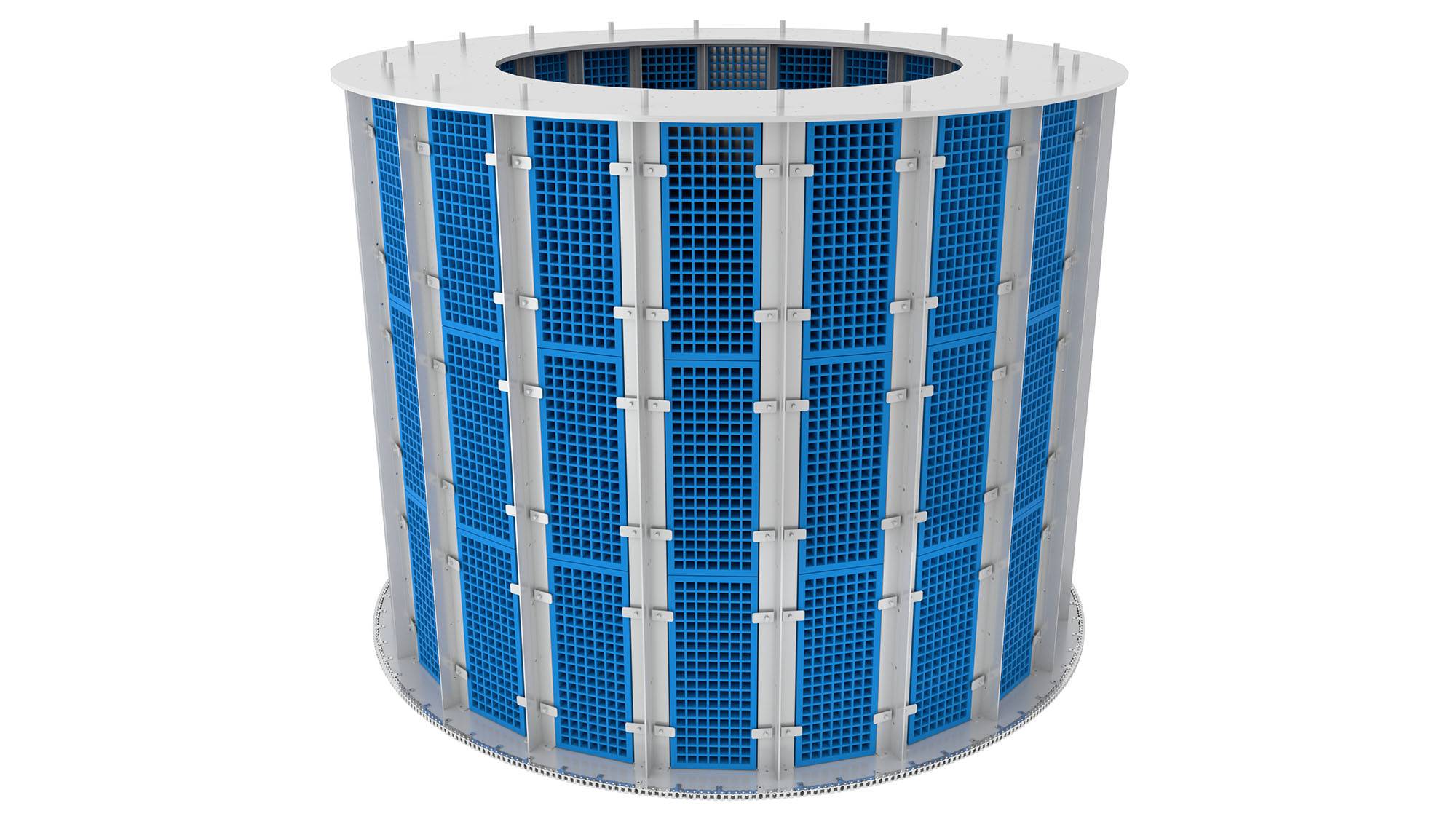

Biogas desulphurization is the key and difficult point of biogas engineering: the traditional wet desulphurization process has a huge cost of lye consumption; Dry desulphurization requires regular replacement of fillers, which is time-consuming and dangerous. Environtec BDS series biological desulfurization has completed several engineering cases to date and is proven to be a best practice technology for biogas desulfurization. A typical case shows that the combined operating cost of biological desulfurization is less than 2 cents per cubic meter of biogas.

Environtec has significantly reduced the initial investment cost of biodesulphurization by importing core technology and by localizing tower and filler. As an experienced project management team in China, Environtec ensures the smooth installation and commissioning of each project and provides responsive after-sales service.

Principle introduction

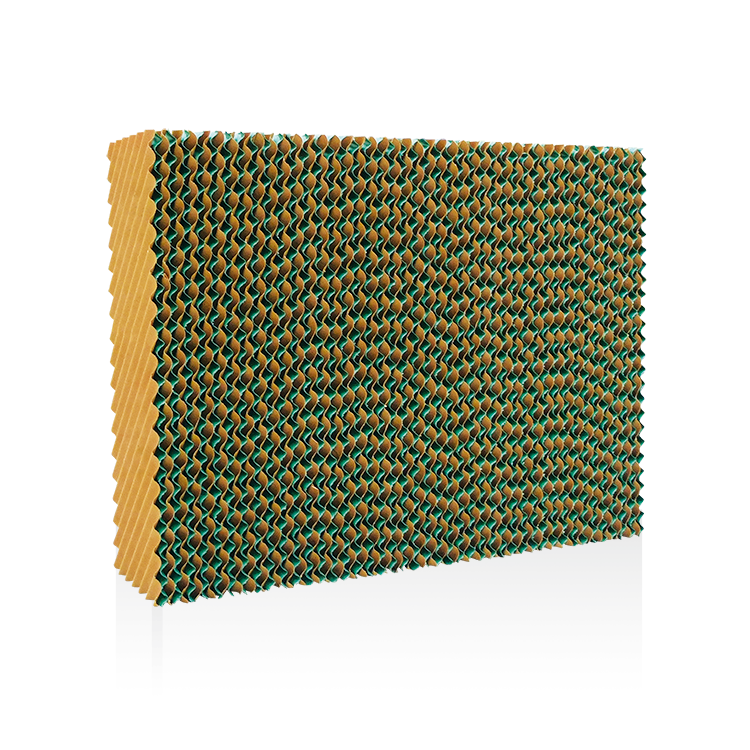

A certain amount of air is introduced into biogas containing hydrogen sulfide, and a large number of biological fillers are installed in the reactor, which provide sufficient space for bacteria to multiply. The circulation of nutrient solution (NPK) keeps the filler moist and replenishes the nutrients needed for bacterial growth and reproduction. Thiobacillus and thiobacillus absorb hydrogen sulfide in the process of metabolism and convert them into elemental sulfur, which is then converted into sulfuric acid.

The chemical reaction is as follows:

H2S + 2O2 → H2SO4

2 H2S + O2→ 2 S + 2 H2O

S + H2O + 1.5O2 → H2SO4

The generated dilute sulfuric acid is buffered and neutralized by the nutrient solution and discharged from the system together with the nutrient solution, and the process begins again.

Search

Search