Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

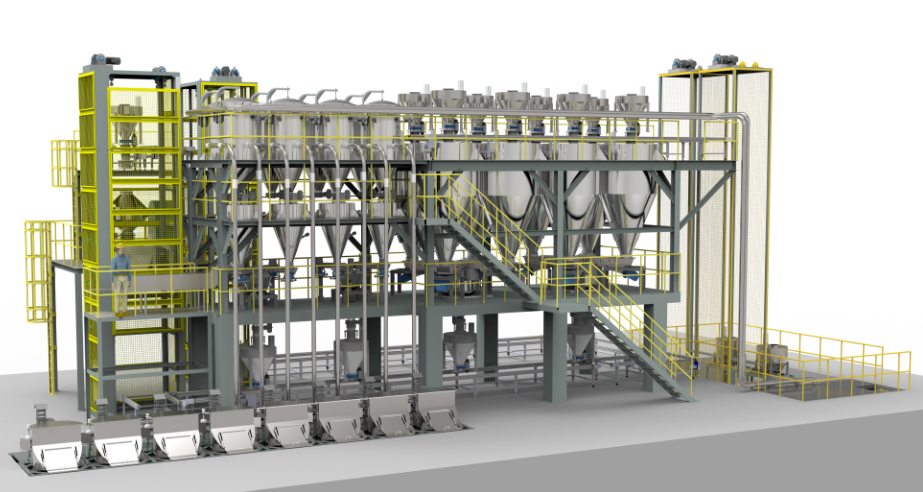

Environtec DT series dry desulphurization is a simple, efficient and relatively low-cost desulphurization method, which is generally suitable for biogas desulphurization with H2S concentration <2000ppm. When dry desulphurization is combined with other desulphurization methods such as biological desulphurization, the service time of the filler can be greatly extended, and it can be used as a good fine desulphurization and process guarantee.

Structure and principle

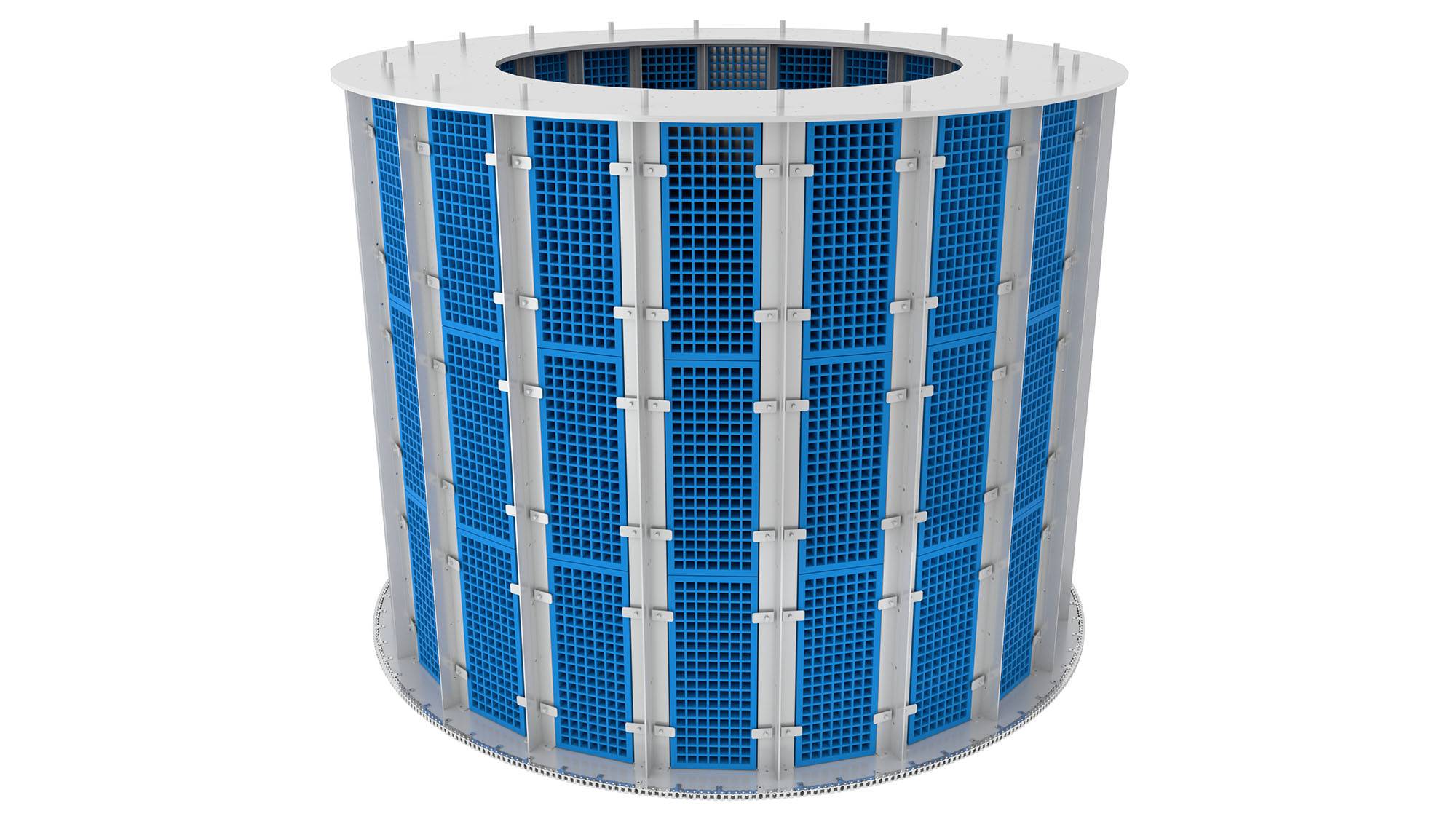

Dry desulphurization mainly includes the main steel structure, desulfurizer filler, loading hopper, unloading hopper, lifting device, double-layer air tight valve, pressure gauge, temperature meter and other components.

Desulfurization tower is usually designed for 1 use 1 standby, alternate use; The desulfurization tower with loading and unloading hopper and double-layer air tight valve can be designed as a single set of independent use, no need to switch when replacing the filler. Biogas containing hydrogen sulfide (H2S) enters the bottom of the desulfurization tower, and in the process of passing through the desulfurization filler layer to the top, H2S and the desulfurization agent undergo the following chemical reaction:

Step 1: Fe2O3•H2O + 3 H2S = Fe2S3 + 4 H2O (desulfurization)

Step 2: Fe2S3 + 3/2 O2 + 3 H2O = Fe2O3•H2O + 2 H2O + 3 S (regeneration)

The biogas containing hydrogen sulfide first reacts with the desulfurizer with relatively high load at the bottom inlet, and the desulfurizer layer with low load is located at the upper part of the reactor. By setting the appropriate biogas airspeed and linear speed, dry desulfurization can achieve good fine desulfurization effect. When the discoloration of the desulfurizer is observed, or the system pressure loss is too large, the waste desulfurizer should be removed from the bottom of the tower, and the same volume of fresh desulfurizer should be added to the top of the tower.

Search

Search