Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

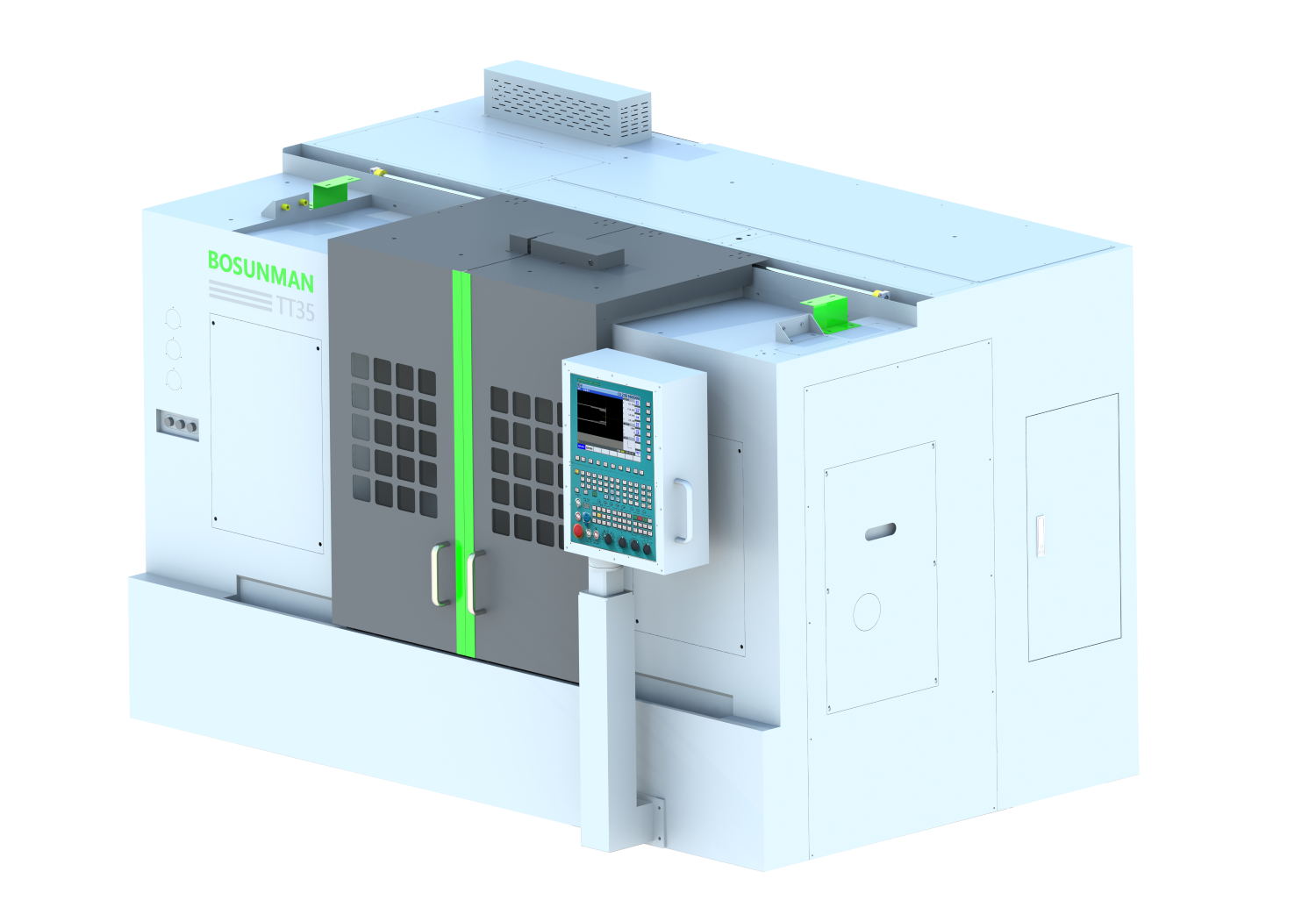

The main characteristics of CNC internal grinding machine

1, the sand wheel shaft adopts high speed and high rigidity precision electric spindle to drive CBN grinding wheel to improve grinding efficiency and grinding quality;

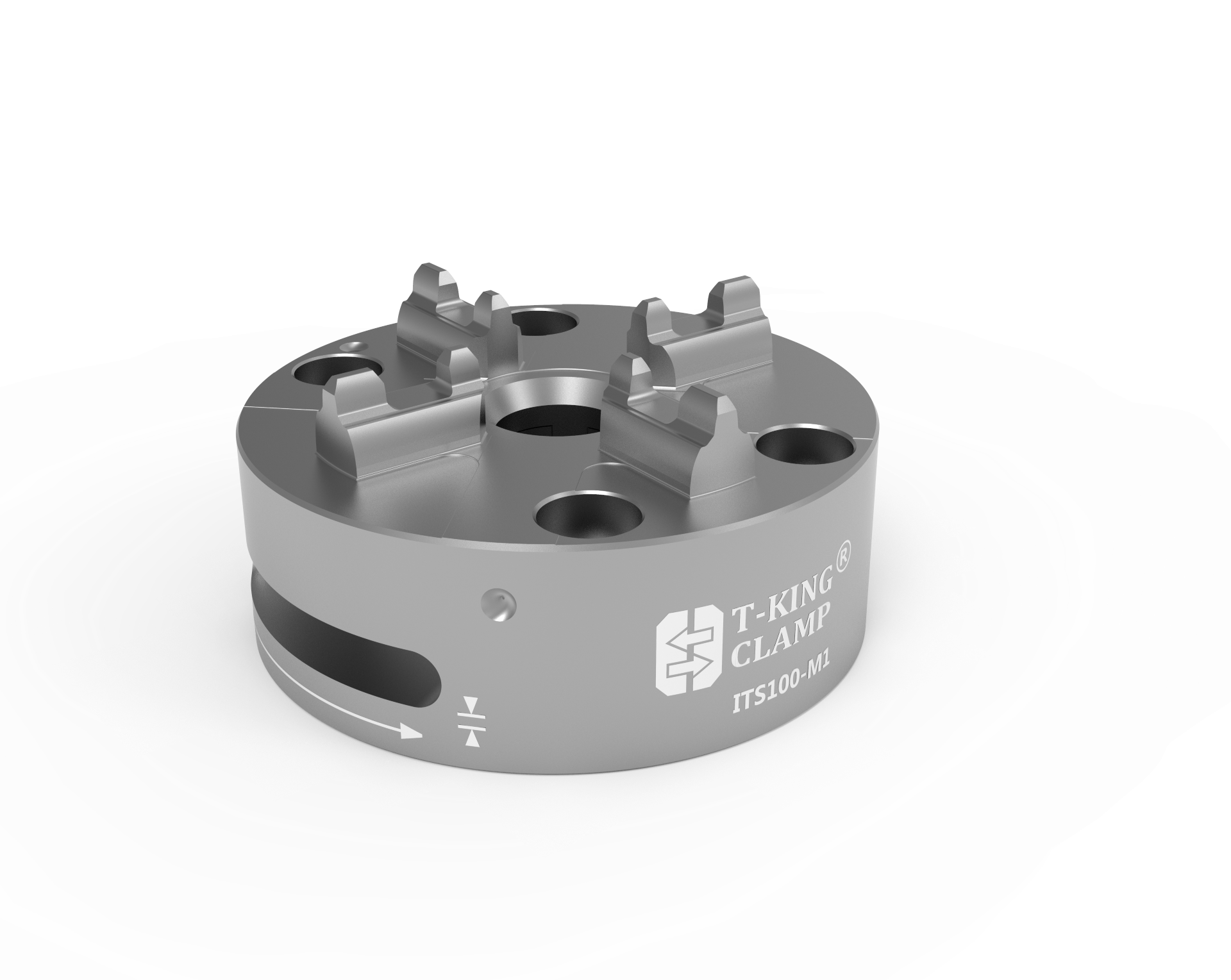

2, the workpiece spindle adopts the box structure, the workpiece positioning adopts the suction cup and the slider positioning, the use of electromagnetic force card, the workpiece rotation accuracy is not affected by mechanical error, the rotation accuracy is high;

3, horizontal feed axis (X axis) table using linear roller guide, high rigidity, good sensitivity, AC servo motor through the ball screw drive table movement, high positioning accuracy, to ensure dressing and grinding feed accuracy;

4. The longitudinal feed axis (Z axis) table adopts the flat-V plaster-coated sliding guide rail, which has high guiding accuracy, strong bearing capacity and good vibration resistance. AC servo motor is used to drive the table movement through the ball screw.

5, the use of rear plug-in active measuring instrument to achieve the full closed-loop control of parts processing size;

6, visual programming: 15 inch touch screen, easy to operate, all Chinese interface.

7, the use of adaptive control processing, to ensure the stability of the workpiece, consistency.

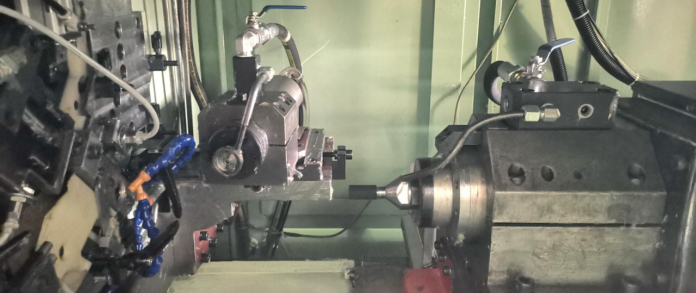

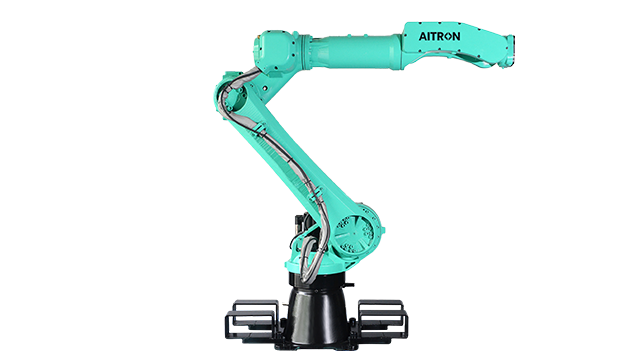

The workpiece is rolled into the feed channel and sent to the machining position by the lifting manipulator. During processing, the X-axis transverse feed of the workbench removes the machining allowance, while the Z-axis of the workbench oscillates. When the grinding wheel grinds the workpiece, the active measuring claw detects the inner diameter of the workpiece online. The lifting manipulator will pull the workpiece to the rolling out position, and the workpiece will roll out from the discharge path; The dressing of the grinding wheel is realized through the roller dresser. The X axis of the table is fed horizontally, and the Z axis of the table is fed longitudinally to realize the dressing of the entire grinding wheel surface.

Search

Search