Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

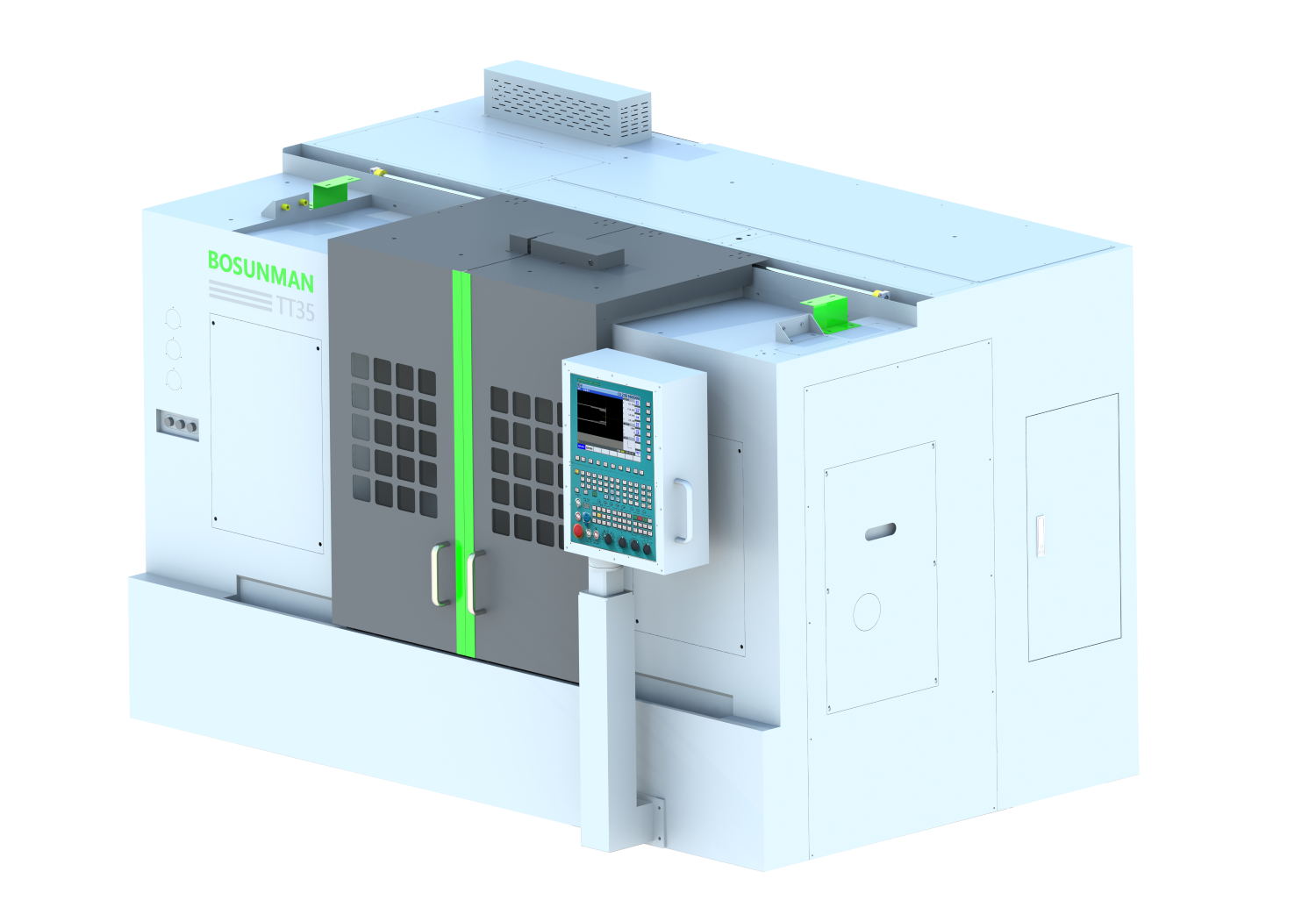

Precision CNC double end grinding machine

1. Equipment structure diagram and plane layout diagram.

2. Manually place the parts in the fixture, the machine automatically sends the workpiece into the processing area, automatically completes the processing process, and the finished product is taken out by the operator;

3. The equipment has the function of automatic grinding wheel dressing and automatic compensation;

4. Normal working conditions of the equipment:

Ambient temperature: 2-45℃

Relative humidity: ≤90%

Power supply voltage: 380V±10%, 50Hz (three-phase four-wire system)

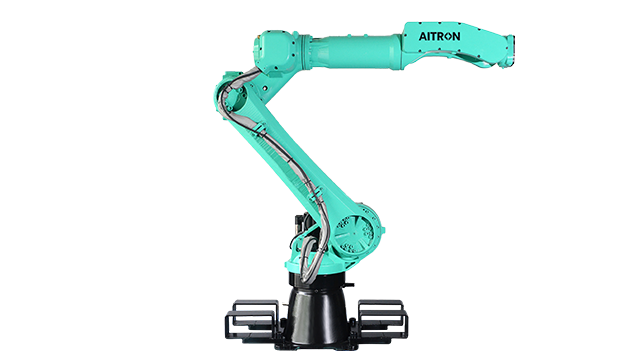

5. In the process of adjustment and use, the equipment has a safety protection device to prevent personal injury caused by misoperation; In the process of parts processing, the equipment has the function of personal safety protection;

6. The equipment has alarm and fault content warning and color (three-color light) alarm function.

7. The equipment has the functions of parts processing count and grinding wheel dressing count, and the single processing beat is displayed on the LCD touch screen;

8. Control cabinet and operating panel:

8.1 The control cabinet is fixed on the side of the machine tool, and each control wire is hidden in the cable box.

8.2 The electric cabinet has good lighting, and the cooling system is installed for cooling and cooling, and the electric cabinet door is reliably sealed.

8.3 Install one or more emergency stop switches in the appropriate operating position.

8.4 Indicators and switches are installed in advance according to the function, and can be expanded, reserving spare holes.

8.5 As far as possible, all electrical control components are concentrated in the main electrical cabinet and arranged in an orderly manner.

8.6 The operation panel is a 24V low-voltage circuit to ensure the personal safety of operators and maintenance personnel.

8.7 Different potentials with different colors of wires (AC power supply A phase: yellow, B phase: green, C phase: red; 24V control loop unified use of blue wire; Ground cable: yellow-green.) .

8.8 Both sides of the terminal are covered with cable codes (white overall cable codes, printed in black).

8.9 The cable length should be appropriate. Spare cables should be reserved. No intermediate cable should be connected.

8.9 Sufficient maintenance space is reserved between the electrical cabinet and the components in each distribution box.

8.10 The ground cable is properly connected and a wiring bar (metal material) is provided. Each branch has a separate terminal post. The ground cable is connected between the door of each electrical box and the electrical box.

8.11 Each electrical component is marked with a visual identifier and affixed to the surface of the slot or the body of the component (consistent with the manual).

9. The equipment has flow monitoring and alarm function;

10. The equipment has short circuit, overload and other safety protection functions;

11. The operation panel display adopts not less than 9 inches LCD color touch display;

12. Color of the equipment shall provide Party B with the color card number and specify the color (color difference is allowed). The "operation panel" and other prompt or warning words on the machine tool are in Chinese;

13. Party A reserves the automatic loading and unloading function interface in the equipment.

14. Replace the machine type, the workpiece is higher than the thickness range of the fixture, only need to replace the fixture core on the fixture.

Search

Search