Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

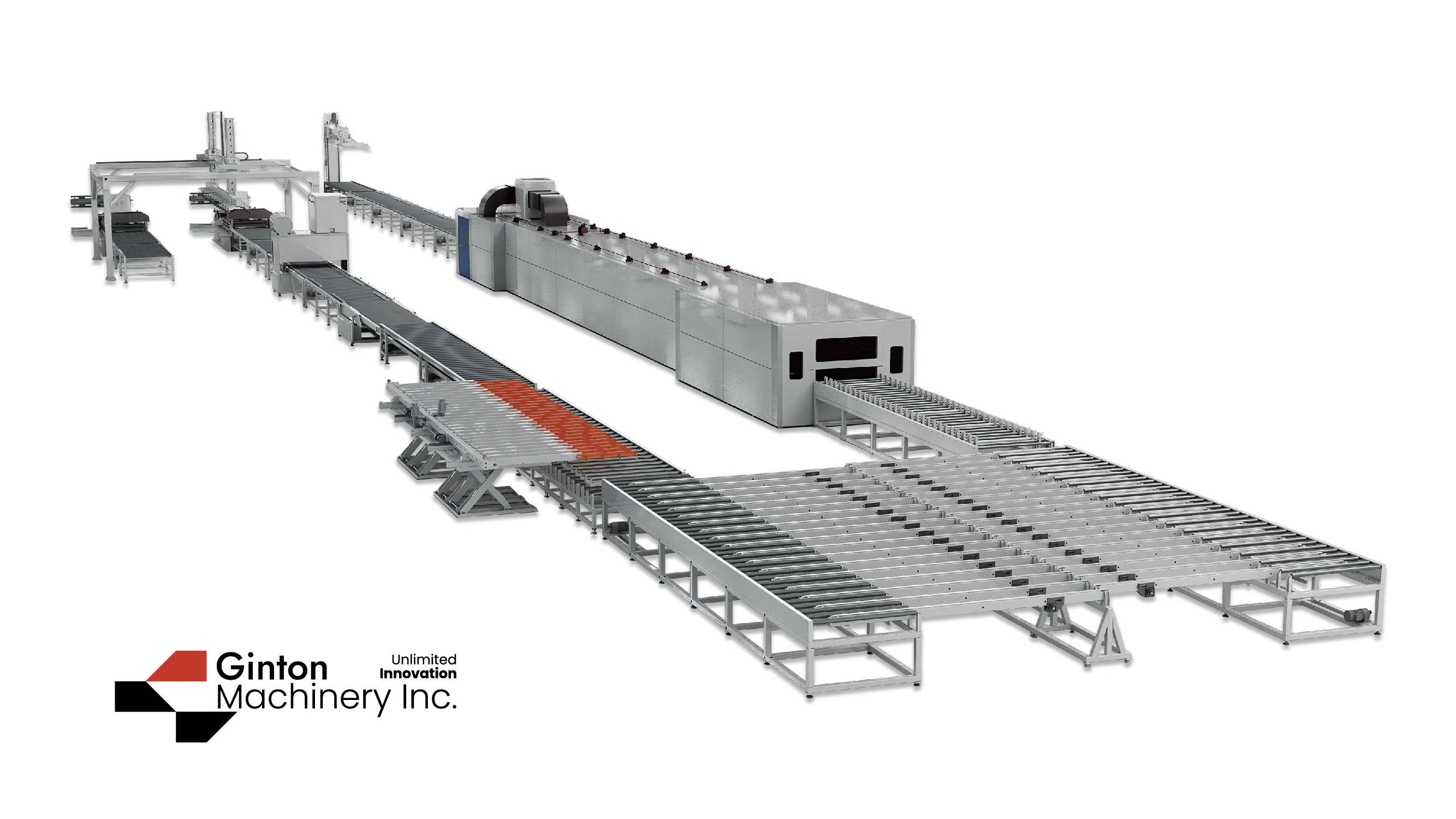

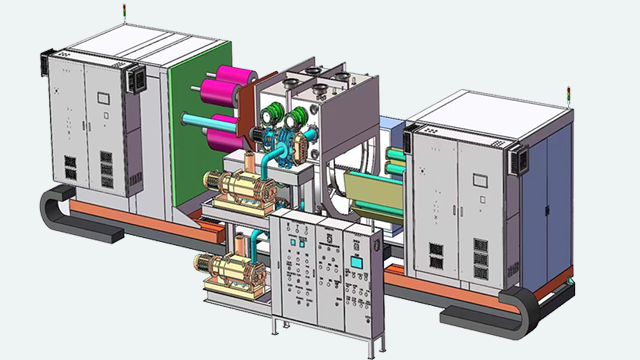

Sanding and CTS system matches with continuous press or large scale multi-daylight press production line. The board stack will be pushed into sanding line piece by piece and pre-stack to a book after sanding. Then the formed book will be sent into cutting saws to get final required size. Finally the finished book will be stacked to certain height before discharge.

Technical Features of Sanding and CTS line

1. Provide one-stop solutions for sanding, cut to size and control. Operation becomes more convenient, efficient and cost saving

2. Adopt advanced technologies like continuous feeding, high speed pre-stacking and large saw blade cutting, to meet production requirements of ultra-thin board, large capacity and high speed

3. Integrated with 3 types of board pushing, ensure high efficiency and stable performance with ultra-thin board and medium & thick board

4. Innovated advanced saw base assembly to enable less wearing of blade, longer lifetime and fine cutting surface without black mark

5. Operate with Siemens S7 series profibus control and IPC, to realize auto-adjustment of cutting patterns, highly automated

6. Updated production information management system, manage equipment, output, consumptions at all time

7. Over 130 sets delivered to market, fulfill different process requirement for MDF, PB, OSB, Plywood etc

Main technical data for Sanding and CTS Line | ||

Main data | Unit | 4—9ft sanding and Cts line |

Capacity | m³/y | 200000—600000 |

Cutting width | mm | ≤2950 |

Cutting length | mm | ≤7500 |

Cutting tolerance(diagonal error) | mm | ≤2 |

Cutting cycle | s | 65—100 |

Feeding stack height | mm | 2500—4000 |

Blade diameter | mm | Φ730—Φ770 |

Cutting height | mm | 210—230 |

Main saw motor | kw | 55/75 |

Air pressure | Mpa | 0.6 |

Pushing frequency | times/min | ≤25 |

Sanding speed | m/min | 20—120/150 |

Features of Sanding and CTS line

Section Name | Key Feature | Key Machine | Key Feature |

Board feeding segment | Connection to automatic storage system seamlessly Stable board pushing Multiple pushing method Continuous board feeding Protection board recycle system | Board feeding segment | Stable board pushing Multiple pushing method |

Main hydraulic lifter | Adjustable lifting speed Stable lifting | ||

Buffer hydraulic lifter | Stack holding system Stable lifting | ||

Continuous board feeder | Reduce stack transit time | ||

High speed transportation segment | Stable feeding Speed adjustable | Alignment Roller Conveyor | Automatic centering Adjustable blocking Stable feeding Speed adjustable |

Booking segment | Straight booking Non-stop running Rejected board stacking | Rejected board stacker | Rejected board removal Straight stacking |

Booking station | Straight booking Double-layer booking Non-stop running | ||

Cutting segment | Mobile cutting saw Compact structure High precision positioning High cutting quality | Servo Feeder | Linear guiding rail High precision positioning Compact structure |

Book saw | High cutting quality Stable cutting Short cycle time Multiple option for blade | ||

Discharger | Compact structure No impact on cutting speed | ||

Finished board stacking segment | Carrier stacking system Compact structure Straight stacking Low cost High reliability | Board discharger | Compact structure High reliability |

Stacker | Straight stacking High reliability | ||

Outfeed hydraulic lifter | High speed High reliability | ||

Protection board feeding segment | Multiple option Draw-type Vacuum-type Pushing-type | Protection board conveyor | Protection board thickness>8mm Protection board stack height<600mm High adaptation |

Search

Search