Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

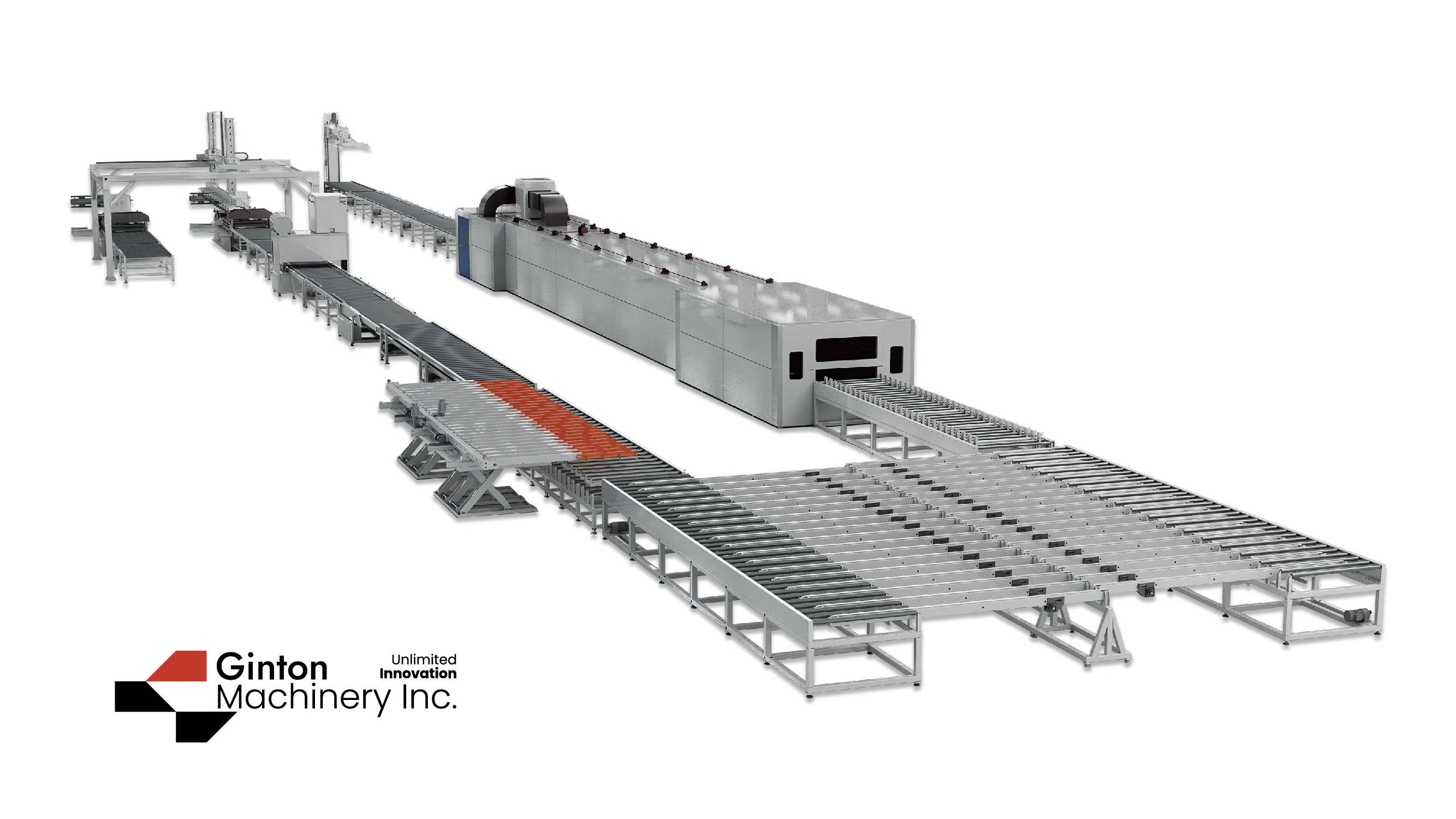

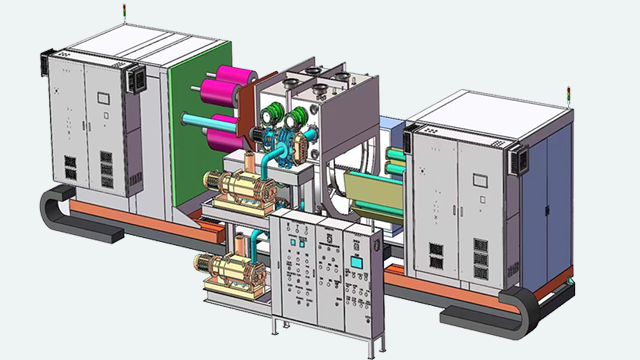

BSG_V Sander

Main features

1. The calibration and finishing of multiple types of boards i.e. MDF, PB, OSB, Plywood, calcium silicate board, etc.

2. Design different maximum speed series i.e. 50m/min, 100m/min, 150m/min, to meet the different application economically.

3. Optimized power design and direct driving of contact roller help to improve transmission efficiency and reduce power consumption by 10% and belt consumption by 16%.

4. The seamless eccentric mechanism of the contact roller makes it easy to adjust. Optimized sealing design of contact roller, convenient maintenance of main bearing.

5. Reinforced structure design of the main frame, golden diameter-to-thickness ratio of the contact roller, dynamic balancing precision less than 1g, less vibration leads to less mark in the board surface.

6. Standard sanding-shoe design of the pad, optional choose for slide pad and water cooling system for pad to make a better surface finishing.

7. The thickness adjustment driven by the ball-screw mechanical system can yield accurate thickness control.

8. The separate driving system for top feeding roller and bottom feeding roller can avoid slide in thick board sanding and efficiency is increased by 10% to 15%.

9. The optimized du-dusting design by compensating fresh air continuously help to reduce air consumption by 12% to 15%.

10. Informatization control system manages equipment, output and consumption.

11. Optional configuration for polishing head and super-thin board sanding head.

BSG_V Sander technical data list

Model |

| BSG_V-13 | BSG_V-16 | |

Parameters | Unit | |||

Board Width | mm | 1300 | 1600 | |

Thickness range | For multiple opening press | mm | 3~50 | 3~50 |

For continuous press | mm | 2~50 | 2~50 | |

Working tolerance | mm | ±0.05 | ±0.05 | |

Feeding speed | For multiple opening press | m/min | 6~50 | 6~50 |

For continuous press | m/min | 2~90/120 | 2~90/120 | |

Opening of upper frame | mm | 280 | 280 | |

Sanding belt linear speed | m/s | 22~33 | 22~33 | |

Sanding roller motor | KW | 75/90 | 90/110 | |

Combined decks motor | KW | 55 | 55/75 | |

Fine sanding motor | KW | 55 | 55 | |

Incline fine sanding motor | KW | 45 | 55 | |

Polishing motor | KW | 18.5 | 18.5 | |

Sanding belt width | mm | 1350 | 1650 | |

Compressed air consumption | m³/h | 4~7 | 4~7 | |

System pressure | Mpa | 0.6 | 0.6 | |

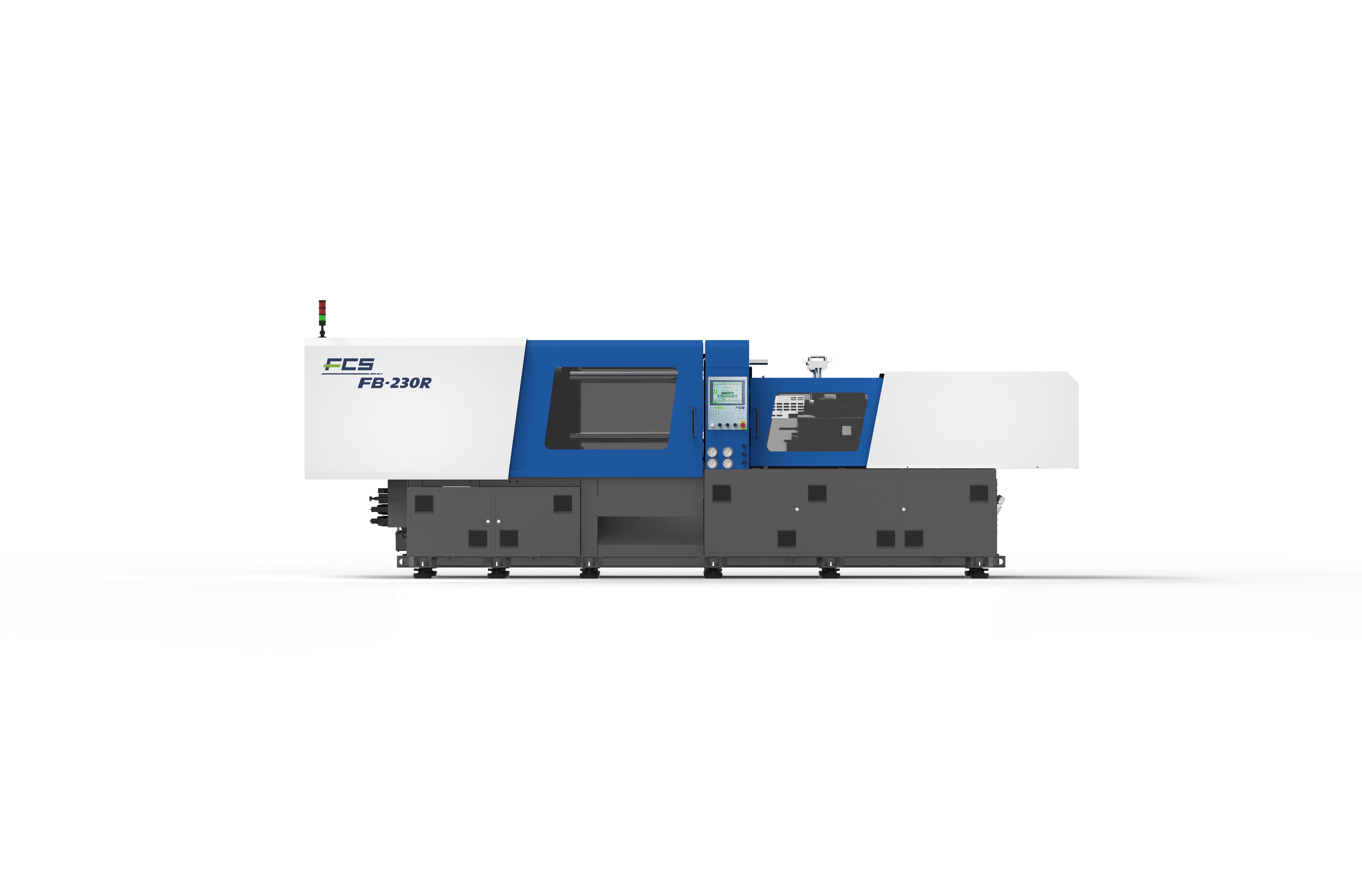

BSG-V4i Wide-belt Sander

Main features

1. Designed for super-thin board (~1.6mm) and high-speed (~150m/min) sanding.

2. Reinforced structure design of the main frame, golden diameter-to-thickness ratio of the contact roller, less vibration leads to less mark in the board surface.

3. Multiple sanding setting available, i.e. top-backward and bottom-forward, front-forward and end-backward, top-bottom matrix, slide pad technology, etc.

4. Pneumatic clamping system and centralized feeding system achieves smooth and stable board feeding.

5. Centralized lubrication system makes easy for machine maintenance.

6. Informatization control system manages equipment, output and consumption.

7. Digital automation technology available, i.e. sanding head servo adjustment, sanding belt self-tracking system, sanding belt linear adjustment system, etc.

BSG_V4i Wide-belt Sander technical data list

Technical parameters Model | Unit | BSG_V4i-19 | BSG_V4i-23 | BSG_V4i-26 | BSG_V4i-29 | |

Max. working width | mm | 2000 | 2300 | 2600 | 2900 | |

Thickness range | mm | 1.6~50 | 1.6~50 | 1.6~50 | 1.6~50 | |

Feeding speed( servo adjustment) | m/min | 6-50 10-90 20-150 | 10-90 20-150 | 10-90 20-150 | 10-90 20-150 | |

Opening of upper frame | mm | 300 | 300 | 300 | 300 | |

Working tolerance | mm | ±0.075 | ±0.075 | ±0.075 | ±0.075 | |

Main Motor | KW | UP to 132 | UP to 160 | UP to 160 | UP to 160 | |

Feeding motor | KW | UP to 22 | UP to 30 | UP to 30 | UP to 30 | |

Abrasive belt size | Roller type frame size( width×length) | mm | 2050×3250 | 2350×3250 | 2350×3250 | 2650×3250 |

Combined/find sanding frame (width × length) | mm | 2050×3250 | 2350×3250 | 2350×3250 | 2650×3250 | |

Dust discharge air volume | Roller Sand Frame | m³/h | 12800 | 15000 | 17000 | 19000 |

Combined head | m³/h | 10000 | 12400 | 14000 | 16500 | |

Fine sanding head | m³/h | 10000 | 12400 | 14000 | 16500 | |

Cleaning device | m³/h | 2700 | 3100 | 3500 | 3900 | |

System pressure | Mpa | 0.6 | 0.6 | 0.6 | 0.6 | |

Compressed air | m³/h | 4~7 | 4~7 | 4~7 | 4~7 | |

Equipment weight | t | 22~39 | 24~43 | 26~45 | 28~48 | |

Search

Search