Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

This powder ore wind dry magnetic separator is a selection equipment for fine-grained dry materials. It is suitable for magnetite separation in arid and cold areas. It is also suitable for iron recovery and processing of fine-grained steel slag.

Application

This powder ore wind dry magnetic separator is a selection equipment for fine-grained dry materials. It is suitable for magnetite separation in arid and cold areas. It is also suitable for iron recovery and processing of fine-grained steel slag.

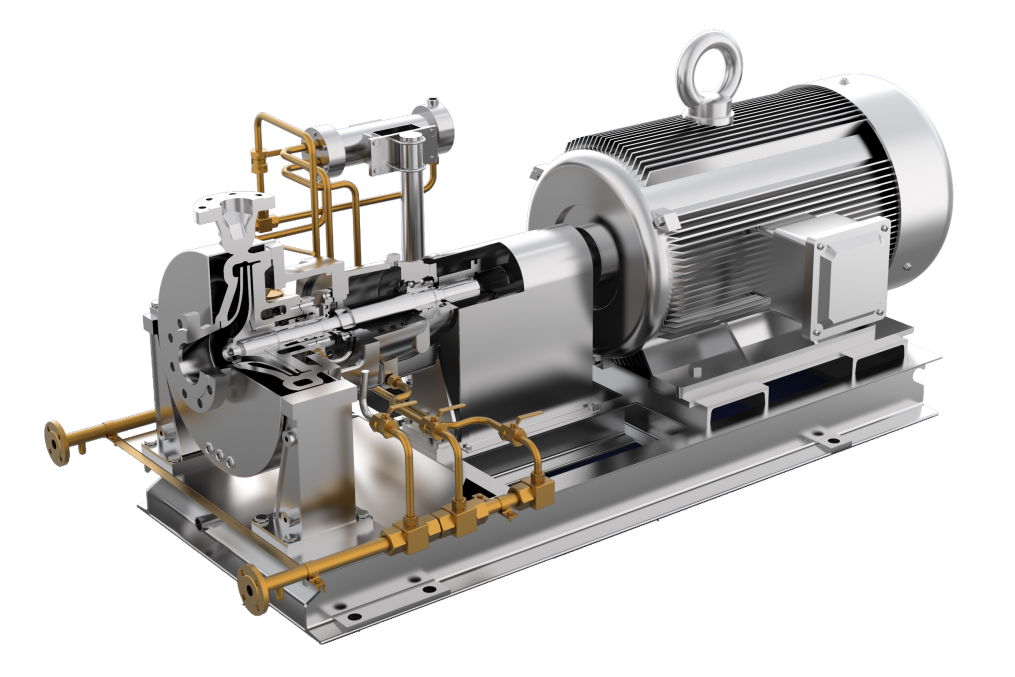

Working Principle

The minerals are directly fed to the surface of the drum from the ore feeding inlet through the vibrating ore feeding device. The magnetic minerals are adsorbed on the surface of the drum under the action of magnetism and rotate with the drum at high speed. During this process, the minerals on the surface of the drum are affected by large wrap angles and multiple magnetic poles. Under the combined action of the magnetic pulsation, magnetic stirring device and blowing device, the impurities and poor conjoined organisms in the minerals are effectively removed, thereby improving the grade of the concentrate. After sorting, the magnetic minerals rotate with the drum to the non-magnetic area, under the action of the unloading device, drum centrifugation and gravity, it is enriched from the concentrate outlet to the concentrate box and becomes concentrate. The non-magnetic minerals or poor conjoined minerals are removed from the tailings outlet under the action of gravity and centrifugal force, becoming tailings or middlings.

Technical Features

◆ Adopt vibrating feeder to feed materials.

◆ The magnetic system adopts multi-magnetic pole, large wrap angle (up to 200-260 degrees), high field strength (3000-6000Gs) design, and the magnetic system structure can be changed according to the mineral properties to

achieve reasonable mineral processing indicators.

◆ The linear speed of the drum can be adjusted within 1-20m/s, and the appropriate linear speed can be selected according to the properties of the ore.

◆ The drum is made of non-metallic material.

◆ The inner surface of the drum is equipped with a magnetic stirring device.

◆ It has a specific air knife structure, wind compensation device and dust removal device (appropriate parameters can be selected according to the ore properties and index requirements)

◆ The surface of the drum is equipped with an ore unloading device.

◆ The transmission system adopts frequency conversion speed regulation.

Search

Search