Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

Product Description

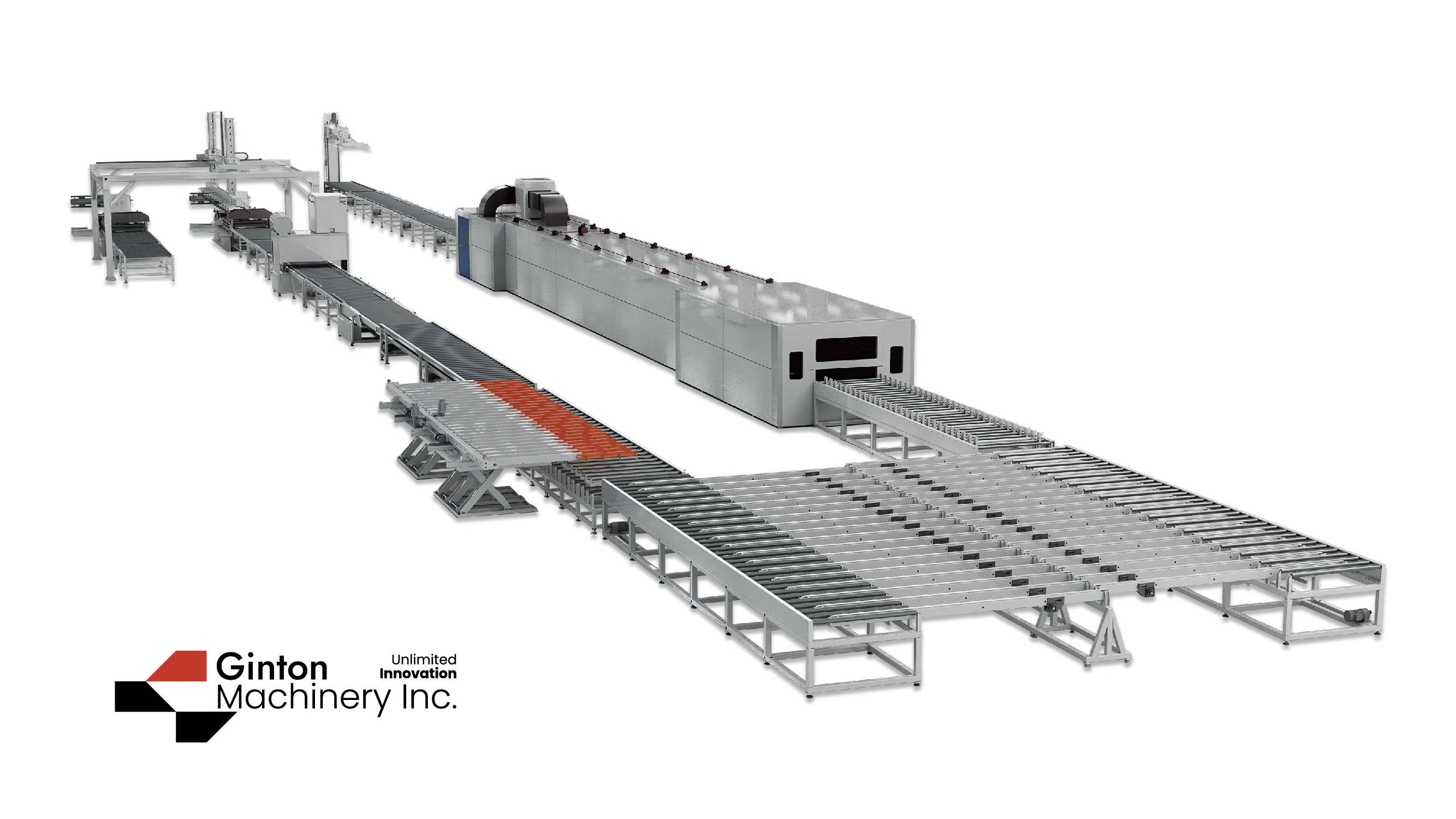

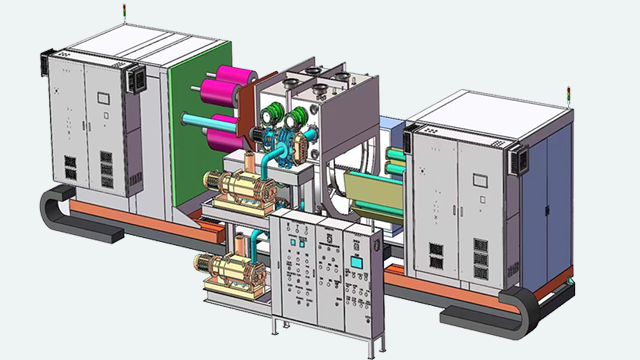

Double Wire Air Borne Drying Pulp Machine is a kind of specialized machine for producing commercial pulp, and mainly used for producing dry pulp sheet with Wood Pulp, Bamboo Pulp, Straw Pulp, Sugarcane Pulp, Kenaf Pulp,Hemp Pulp and Cotton Pulp as its raw materials.

The machine mainly consists of Consistency Headbox, Double Wire Forming Section, Big-diameter Roll Press Section and Hot Air Dryer. It passed the Provincial Appraisal of the New Products in the year 2007 and was identified as "State-level Important New Product". It can substitute for imported products because of its advanced technical performance.

Technical Advantages

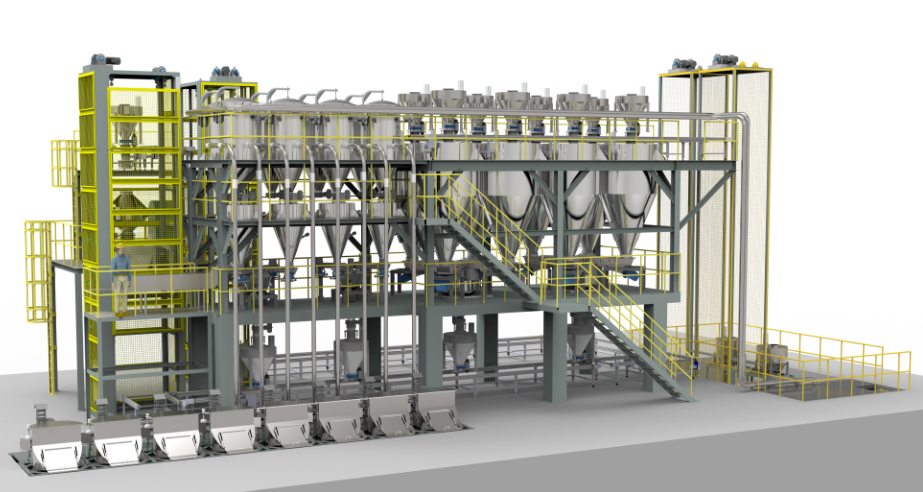

■Use high consistency headbox to improve pulp approaching consistency and to lower power consumption in pulp delivery;

■In double wire forming section, reduce or cancel vacuum dewatering parts to reduce power consumption, extend the wire life and also improve the pulp sheet dryness out of the wire section;

■Use big-diameter rolls to improve the pulp sheet dryness out of the press section and reduce steam consumption;

■Dry pulp sheet with hot air, thus there is no hornification and the surface of the pulp sheet can not easily turn yellow so as to improve the quality of pulp sheet;

■Hot air is circulated in closed equipment to increase the utilizing rate and the steam consumption is reduced by 35%;

■Use hot air to dry and hold the pulp sheet, thus the tension is small and the pulp sheet is dried and shrunk evenly so that it is not broken easily;

■Easy maintenance and low maintenance cost;

■Air cooling chamber, which lowers the pulp sheet temperature out of the dryer section, makes pulp sheet storage longer;

■The area occupied by machine is reduced by 35% and building area is reduced by 60%, thus the civil engineering investment is lower.

Search

Search