Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

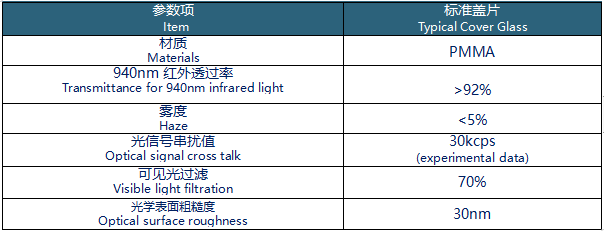

1 The following specifications are the IRC 0X0 standard series cover plates. The size of the cover plates is customized according to the size of the TOF sensor, and the basic structure is the same. Take ST's TOF laser sensor as an example. IRC010 is adapted to ST's VL53L0/VL53L3/VL53L4 series, IRC020 is adapted to ST's VL53L1 series, and IRC030 is adapted to ST's V53L5 series.

2This product is a specially made infrared optical cover sheet for TOF laser ranging sensors. It uses a self-developed high-performance and high-penetration infrared material suitable for 850~930 nm. It has special optical structure design and precise optical processing. Compared with other infrared optical materials on the market, it can minimize the crosstalk of optical signals caused by optical materials and size structure, and minimize the ranging error caused by the cooperation of the cover plate of the TOF sensor. nbsp;

- The IRC010 standard cover slip is integrally injection molded with materials dedicated for TOF infrared. The characteristics of the material itself and high-precision optical processing minimize the optical signal caused by the material and structure when the cover plate is matched with the TOF sensor. Crosstalk.

- The groove on the incident surface of the product is consistent with the size of the chip and can be directly inserted into the chip.

- Adhesive glue is adhered around the groove of the product's entrance surface, which can be directly pasted on the PCB, eliminating the need for additional installation treatment.

- The small size structure of the product fully considers the combination of optics and processing technology. In practical applications, customers only need to make an opening in the shell similar to the size of the cover sheet.

- The completely flat optical surface is suitable for application scenarios with strict appearance requirements, and the overall fit is beautiful and elegant.

- Since the standard cover sheet is not designed to block the path of optical signal crosstalk caused by dust, dirt, scratches, water stains, etc. on the cover surface that may be caused by actual application scenarios, the standard cover sheet is more suitable for a relatively clean environment., there is no application scenario where the surface of the cover sheet is frequently touched.

- During the assembly process, it is necessary to avoid damage to the optical surface of the cover sheet as much as possible to ensure the service life of the cover sheet.

Search

Search