1 / 2

Five-axis CNC Machining Series

Price:

price negotiable

Brand Name:

FLYNASTARCountry Region:

ChinaModel No:

U-260TC

Post Requirements

Post Requirements

FLYNASTAR

Country: China

Main Products: Vertical Machining Series

View more

Price:

price negotiable

Brand Name:

FLYNASTARCountry Region:

ChinaModel No:

U-260TC

Post Requirements

Post Requirements

FLYNASTAR

China

Main Products:

Vertical Machining Series

Product information

Product Features

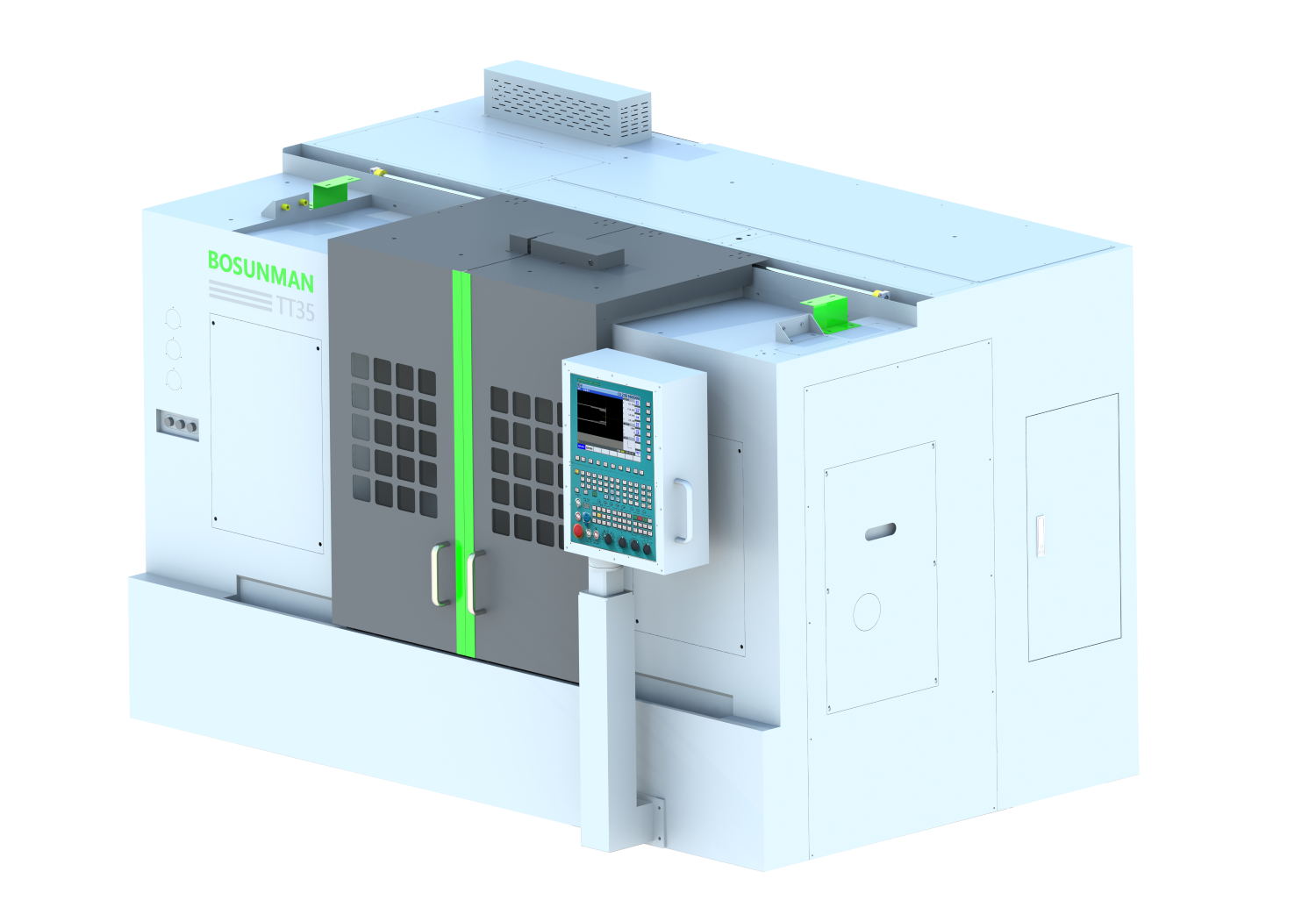

About the features of U-260TC

-CNC machining machine tools with superior cost performance. It can realize drilling, reaming, countersinking, tapping, milling, boring and other processing, and is suitable for processing parts with high precision and productivity requirements. Certain special fixtures and marking processes can be completely omitted, greatly reducing the labor intensity of workers. This machine tool is suitable for drilling and drilling of small and medium-sized plates, plates, shells, valve bodies, cams and other parts with high hole spacing precision in industries such as automobiles, motorcycles, *, *, instruments, meters, electronics, molds, etc. The processing of milling, boring, tapping, etc. is programmed and the production cycle is shortened.

-The five-axis machining center is equipped with full protection, which effectively prevents cutting fluid and chips from splashing around and has a beautiful and generous appearance. It is equipped with a complete set of spindles produced by a well-known professional company in Taiwan, with good performance, strong broaching force and service life; optional CNC The turntable can form four-axis coordinate linkage processing; a spindle oil cooler can be optionally configured; an automatic chip removal device can be optionally configured to cooperate with the bed structure to ensure internal cleanliness.

Product Parameters

Specification Specification | Configuration | Unit | U-260TC |

| Stroke | X/Y/Z axis | mm | 600/400/320 |

| Distance from spindle center to guide way of A axis | mm | 420 | |

| Distance from spindle end surface to turntable | mm | 90-410 | |

| Rotary workbench | Area of workbench (L×W) | mm | Φ260 |

| T-shaped slot | mm | / | |

| Spacing of T-shaped slot | mm | / | |

| Max.load bearing of turntable | kg | 30 | |

| Spindle | Hole taper of spindle | / | BT30 |

| Speed range of spindle | r/min | 0-20000 direct type | |

| Max.power of servo main motor within 30 min | Kw | 5.5 | |

| Continuous rated torque of servo main motor | Nm | 11NM-22NM | |

| Spindle precision | mm | 0.003 | |

| Specification of shank | Standard of shank | / | BT30 |

| Standard of rivet | / | BT30(45°) | |

| Feeding | Fast movement of X/Y/Z axis | m/min | 60/60/60 |

| Cutting feeding speed | m/min | 15000/15000/15000 | |

| Arm lock servo magazine | Magazine type | / | Round disc type |

| Magazine capacity | Handle | 21 | |

| Max.tool diameter of full tool | mm | Φ80 | |

| Max.tool diameter of adjacent empty tool | mm | Φ150 | |

| Switch time of tool setting | S | 1.8 | |

| Mode of tool selection | / | Choose the nearest tool |

All products in the store

Horizontal CNC Machining Series

Compound CNC Machining Series

Five-axis CNC Machining Series

Vertical Machining Center Series

Vertical CNC Machining Center

CNC Vertical Machining Center

You May Like

Industrial robot

High pressure atomization and spraying system

Optical anti-reflection coating continuous line

Fast forging hydraulic press

Double spindle double tool tower turning center

Hermos Precision CNC internal grinder

Industrial robot

Hwavy turret lathe

5 Axis 3D Fiber Laser Cutting Machine

Online density control system

Search

Search