Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

product parameters

| model | Storm-SPIS | Storm-SPID | Storm-2DS | Storm-2DD | Storm-3DS | Storm-3DD |

| lighting system | RGB+White LED ring light source | High-brightness six-channel LED light source | 2D RGB+White LED ring light source | |||

| 3D digital projection | 2D imaging data analysis | 3D four-dimensional digital projection | ||||

| imaging system | 5M (12M optional) industrial high-speed camera, telecentric lens | Industrial high-speed camera 5M (12M optional) | 12M industrial high-speed camera, telecentric lens | |||

| resolution | 12M 8μm 10μm 12μm 15μm | 5μm~15μm | 12M 8μm 10μm 12μm 15μm | |||

| Sports module | C3 grade screw + servo motor | |||||

| FOV size | 40*30mm (12M,10μm) | 36.7mm×30.7mm (5M,15μm) | 30.3*24.5mm (12M,8μm) 40.9*30.7mm (12M,10μm) 56.8*46.0mm (12M,15μm) | |||

| height measurement | Parts up to 8mm can be measured | Parts up to 20mm can be measured | ||||

| Height measurement accuracy | 1μm | 1μm | ||||

| equipment weight | 950kg | 1083kg | 735kg | 870kg | 950kg | 1090kg |

| Machine size (mm) | W1000×D1350×H1800 | W1000×D1600xH1800 | W1000×D1165xH1800 | W1000×D1530xH1800 | W1000×D1350xH1800 | W1000×D1600xH1800 |

| Substrate size (mm) | 50*70~510*460 | Monorail: 50*70~510*590 | 50*70~540*460 | Monorail: 50*70~510*590 | 50*70~510*460 | Monorail: 50*70~510*590 |

| Double track: 50*70~510*330 | Double track: 50*70~510*330 | Double track: 50*70~510*330 | ||||

| substrate thickness | 0.6~6mm | 0.6~6mm | 0.6~6mm | |||

| detection principle | 2D imaging data analysis +3D imaging data analysis | 2D imaging data analysis | 2D imaging data analysis +3D imaging data analysis | |||

| detection speed | 350ms/FOV(2D+3D) | 3-5FOV/sec | 450ms/FOV(2D+3D) | |||

| defect detection | Less tin, more tin, connecting tin, offset, leaking, short circuit, Sharpening, poor shape, etc. | Missing parts, deviation, extreme opposition, monument erection, bridge connection, less tin, Pin floating height, pin bending, OCV, etc. | Missing parts, offset, wrong parts, pole inversion, virtual welding, bridge, damaged parts, Foreign bodies, tin balls, scratches, gold fingers stained with tin, lateral standing, monument erection, Reverse direction, tin connection, empty welding, less welding, component lifting, abnormal welding | |||

| substrate transfer system | Substrate fixing method: Bottom-up fixing, automatic board entry and exit and automatic width adjustment system, in compliance with SMEA standards | |||||

| Track height: 900±20mm | ||||||

| power specifications | AC 220V 50/60Hz 1.9KVA | AC 220V 50/60Hz 1.8KVA | AC 220V 50/60Hz 1.9KVA | |||

| barometric specification | 0.5MPa | |||||

| environmental needs | Temperature: 5-40℃, relative humidity: 25%-80% without frost | |||||

| link port | Standard SMEA interface | |||||

product introduction

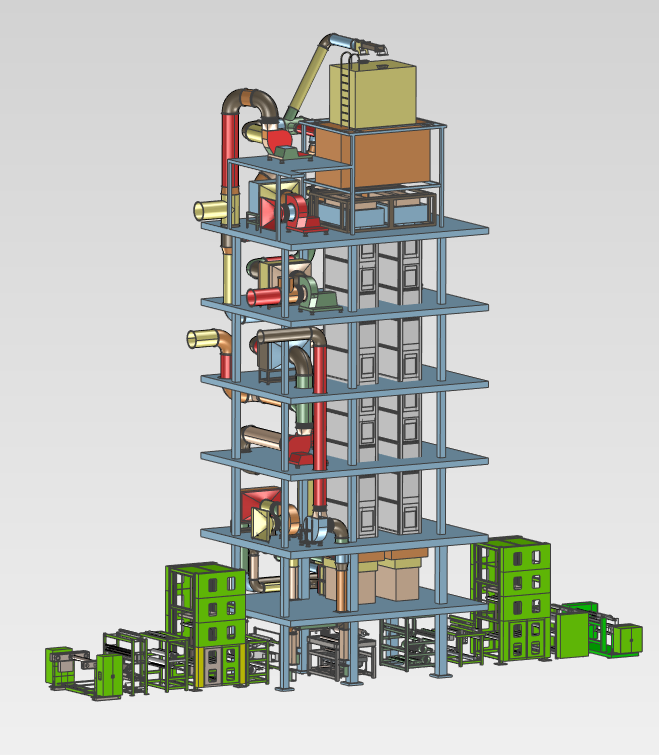

Combination scheme of matrix 3D SPI+2D AOI+3D AOI

The combined use of square SPI and AOI makes it easy to import the three-point comparison function, and displays the data of SPI, AOI in front of the furnace and AOI after the furnace on the SMT production line at the same station, realizing real-time feedback and optimization of the production line process. Improve production quality and yield.

Product advantages:

Customers of the newly developed LINEVIEW software integrate all excess SPI AOI into one set of software for re-adjudication, which can maximize the saving of factory labor costs.

Using the three-point comparison function, data in front of and behind the SPI furnace can be displayed at the same station for process personnel to conduct data analysis and quickly understand where defects occur, thereby improving problem solving efficiency and improving factory quality and production yield.

![[Used] laser](https://cdn.sumecdtx.com/equipment/20230818/928f9346aceb42e3b60670c380399f59.jpg)

Search

Search