Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

Product Parameter

| mode | Legend | Legend-D | Legend-XL | Legend-2000 | |

| Substrate specifications | Substrate size (mm) | 50×70~510×460 | When monorail mode is enabled:50×70~510×590 When dual track mode is enabled:50×70~510×330 | Single section:50×70~680×610 Segmentation:50×70~990×610 Extension rails on both sides:50×70~1200×610 | Single section:50×70~1000×650 Segmentation:50×70~1200×650 Extension rails on both sides:50×70~2000×650 |

| Substrate height limitation | Above:35mm Below:50mm | Above:35mm Below:50mm | Above:35mm Below:50mm | Above:35mm Below:50mm | |

| Substrate thickness | 0.6~6.0mm | 0.6~6.0mm | 0.6~10mm | 0.6~10mm | |

| Track specifications | Track specifications | 900±20mm | 900±20mm | 900±20mm | 900±20mm |

| Track flow direction | Set before leaving the factory according to customer requirements | ||||

| External dimensions(mm) | W1000×D1165×H1800 | W1000×D1530×H1800 | W1300×D1470×H1875 W1720×D1470×H1875(add 210 extension rails on both sides) | W1550×D1475×H1830 W3150×D1475×H1830(add 800 extension rails on both sides) | |

| Equipment weight | 735kg | 870kg | 1150kg | 1350kg | |

| Sports module | Linear motor+grating ruler | ||||

| vision system | Imaging system | Industrial high-speed camera 5M (12M) optional | |||

| Telecentric lens (optional) | |||||

| lighting | High brightness six channel LED light source | ||||

| resolving power | 5μm~15μm | ||||

| FOV size | 36.7mm×30.7mm(5M 15μm) | ||||

| Bending compensation | ±3mm | ||||

| Detection principle | 2D imaging data analysis | ||||

| Detection speed | 3-5FOV/sec | ||||

| Inspection items | Missing parts, offset, pole reversal, monument, bridge connection, insufficient tin, pin floating, pin bending, OCV, etc | ||||

| Power specifications | AC 220V 50/60Hz 1.8KVA | ||||

| Air pressure requirements | 0.5MPa | ||||

| Environmental requirements | Temperature: 5-40 ℃, relative humidity: 25% -80%, no frost formation | ||||

| Communication methods | Standard SMEMA interface | ||||

Product Presentation

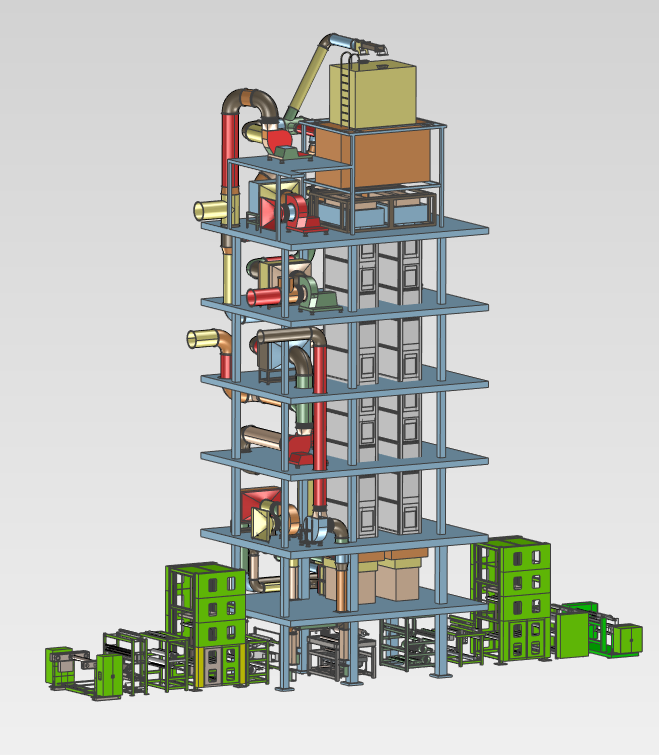

Fully automatic online substrate appearance inspection machine

1. Collect SPI, AOI before and after the furnace, and the entire process data of the reflux furnace, comprehensively analyze the causes of defects, and achieve complete process control of the production line

2. Real time SPC data analysis and processing

3. Centralized management, one person controlling multiple lines, reducing the number of people online

4. Remote debugging and program updates without stopping online

Product advantages:

New visual system

High speed camera for capturing multiple lighting images within the same FOV

New light source, independently controllable six channel light source3 exposure imaging to eliminate Bayer Pattern blur

With clearer and different lighting angles, the detection performance is significantly improved

![[Used] laser](https://cdn.sumecdtx.com/equipment/20230818/928f9346aceb42e3b60670c380399f59.jpg)

Search

Search