Post Requirements

Post Requirements

Post Requirements

Post Requirements

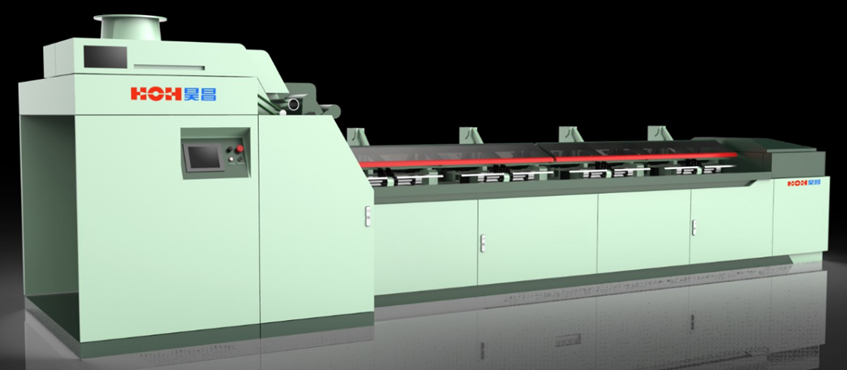

Product information

Specification

| Width | 190,210,230,260,280,300 (cm) |

| Speed | 300-500RPM (designed by material and width) |

| Weft selector | 8-12colors single or double wefts weaving |

| Yarn woven | short fiber Nm4-Nm200, long fiber tex1.7-tex380 |

| Weaving adaptability | the range of yarn etc. Natural fibers (cotton、wool、hemp) chemical fiber、blended |

| Weft density | 1.5-200wefts/cm |

| Reed drive | Bilateral drive,conjugated cam battening system |

| Machine drive | Super motor direct drive host and slow weft insertion mechanism |

Let-off & Take-up method | electronic let-off & take-up |

| Drive device | Super motor,direct drive |

| Open device | adopt electronic dobby and jacquard loom |

| Raising | special electronic raising device and patents designing |

| Weft Variability | self control by electronic let-off and electronic take-up,satisfied vall kinds of terry towel productions |

| Control and examine | Control and examine:adopt microcomputer control system, electronic let-off,electronic weft selecting,automatic wefting, self-check,LCD ect. |

High speed trademark loom has become an indispensable equipment in the textile industry. It is known for its high production efficiency, and is able to complete a large

number of weaving tasks in a short period of time to meet the market demand for fast delivery. At the same time, the quality of the products produced is also very high,

to ensure the brand image and consumer satisfaction. In addition, it also has a variety of weaving capabilities, which can adapt to the design requirements of different fabrics

and patterns.

1. The machine adopts a high degree of automation technology, which greatly reduces the instability brought about by the manual operation, and improves the production

stability and consistency. Strong adaptability makes it easy to cope with a variety of complex working environments, and save labor costs is to save valuable resources for

enterprises. The high quality of the parts ensures long-term durability and minimized maintenance costs.

2. Humanized considerations in design, such as easy to operate, intuitive display interface and convenient troubleshooting process, make the high-speed trademark loom not

only efficient, but also very convenient to maintain. The low energy consumption characteristic further improves its environmental protection performance and reduces its energy

consumption. Overall, the high-speed trademark loom has won wide recognition in the industry for its excellent performance and stable performance.

3. High production efficiency: High-speed trademark looms can be woven at a higher speed, thus improving production efficiency.

4. High quality products: it can accurately control the weaving process and produce high quality knitting products.

5. Diversified weaving ability: it can realize a variety of weaving structures and patterns to meet different weaving needs.

6. High degree of automation: usually equipped with automatic control system, which can realize automated production and reduce manual intervention.

7. Strong adaptability: can adapt to different raw mate

Search

Search