Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

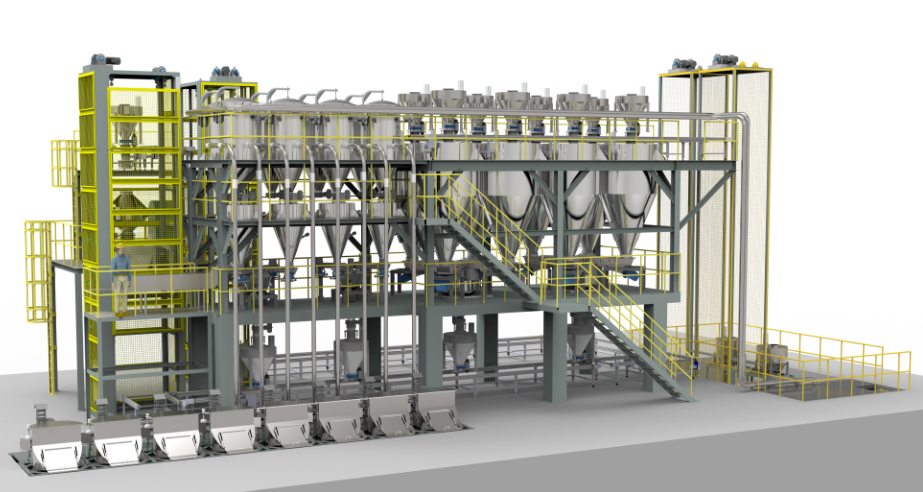

Application:

Suitable for packaging powders, granules, tablets and other materials in industries such as chemical raw materials, fine chemicals, lithium battery materials, pharmaceuticals, feed, fertilizers, building materials, additives, etc.

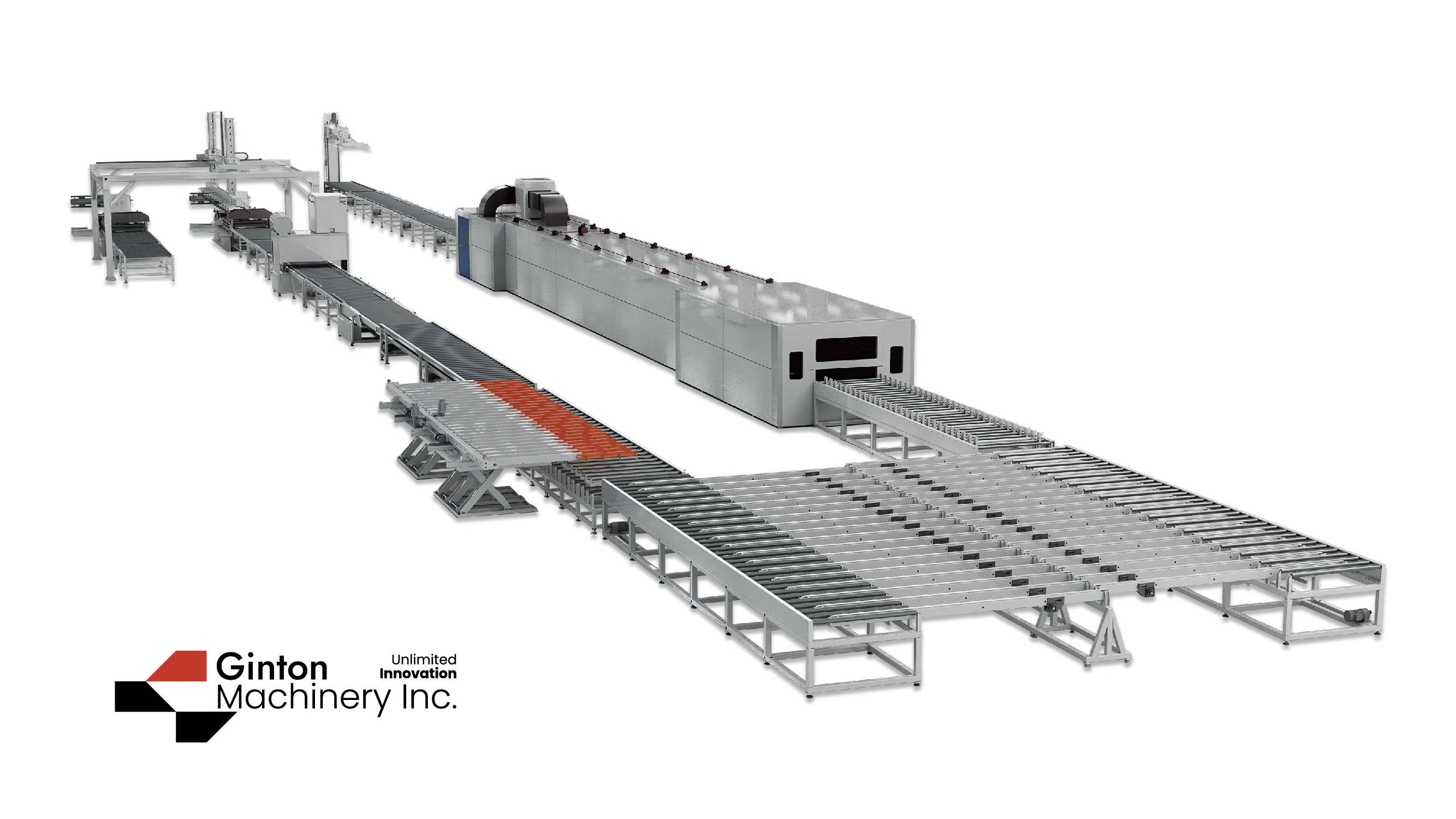

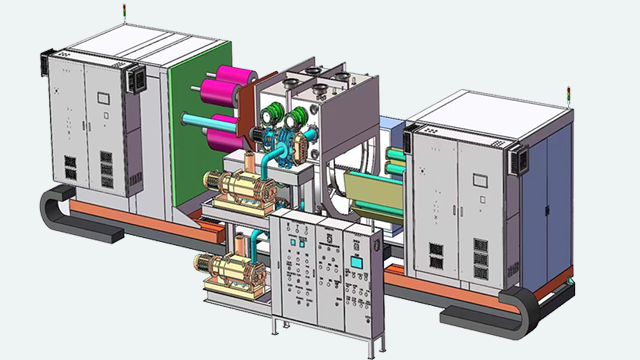

One of the semi-automatic big bag packaging lines: net weight scale

Features and Benefits:

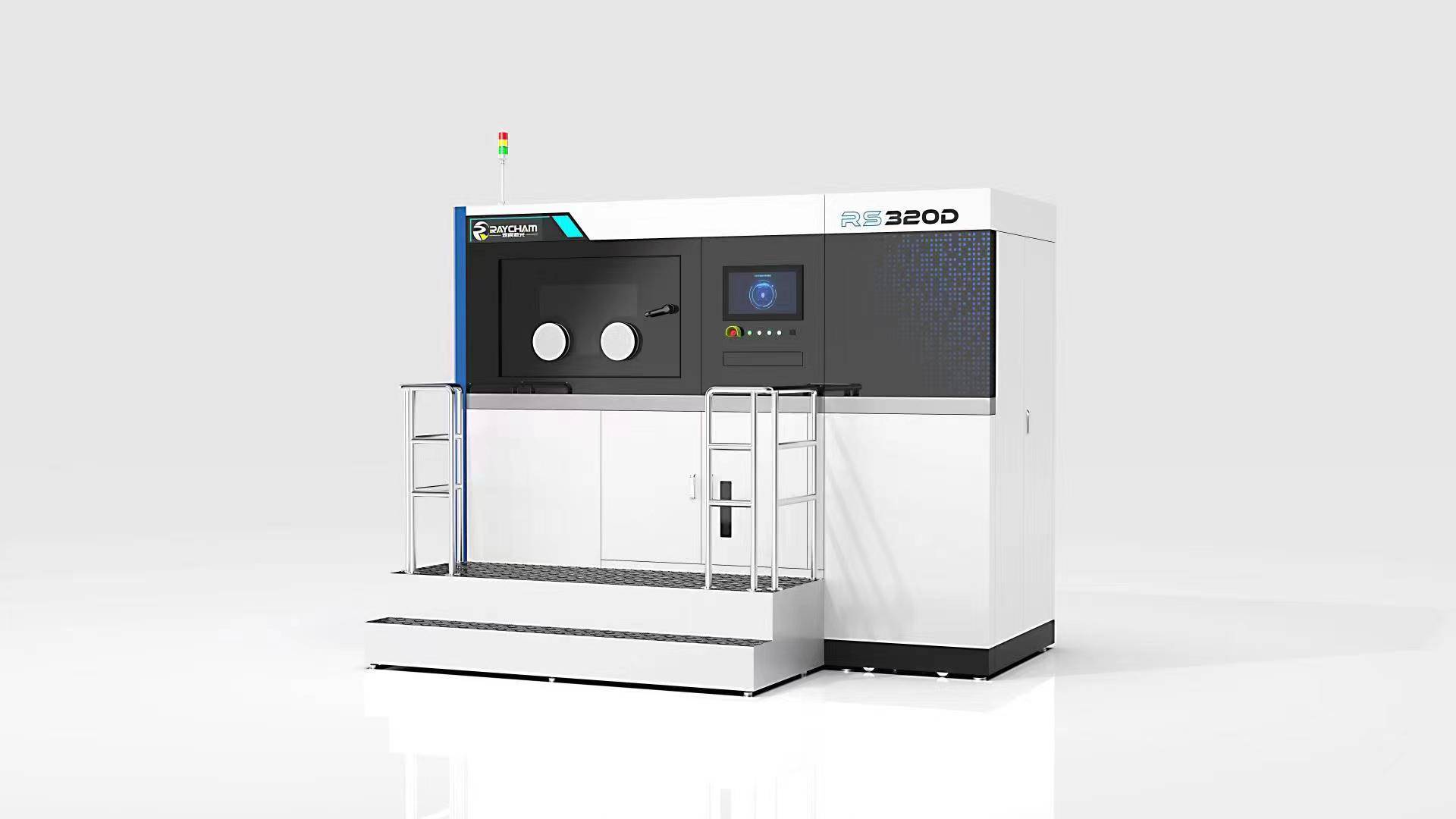

Net weight scale is also known as automatic quantitative packaging scale with bucket. Its control process is to complete the quantitative discharging process through an intermediate weighing hopper. At the beginning, the discharging valve of the weighing hopper is closed, and the upper feeding port is opened for constant value feeding to achieve the target. When the value is reached, close the feeding port, and open the feeding port to put the material into the container or package, and then enter the next control cycle. In order to improve work efficiency, a variety of feeding speeds are available, generally two-speed, that is, fast feeding and slow feeding. High-speed fixed-value control of double-scale rotation can also be used. Features: Integrated structure, high precision and fast speed, this structure is adopted by special weighing control equipment. Using cooperative load cells or weighing modules, weighing instruments and operation buttons, a net weight quantitative control system can be formed.

The main parameters:

1. Packing specification: 20~50kg/bag

2. Packaging capacity: 200-600packs/hour

3. Prefabricated bags: film-coated woven bags, double-layer stitched woven bags at the mouth of the bag, kraft paper bags

4. Bag width range: 400mm-700mm Bag length range: 500mm-1100mm

5. Weighing accuracy: ≤± 0.2%

Search

Search