Post Requirements

Post Requirements

Post Requirements

Post Requirements

Product information

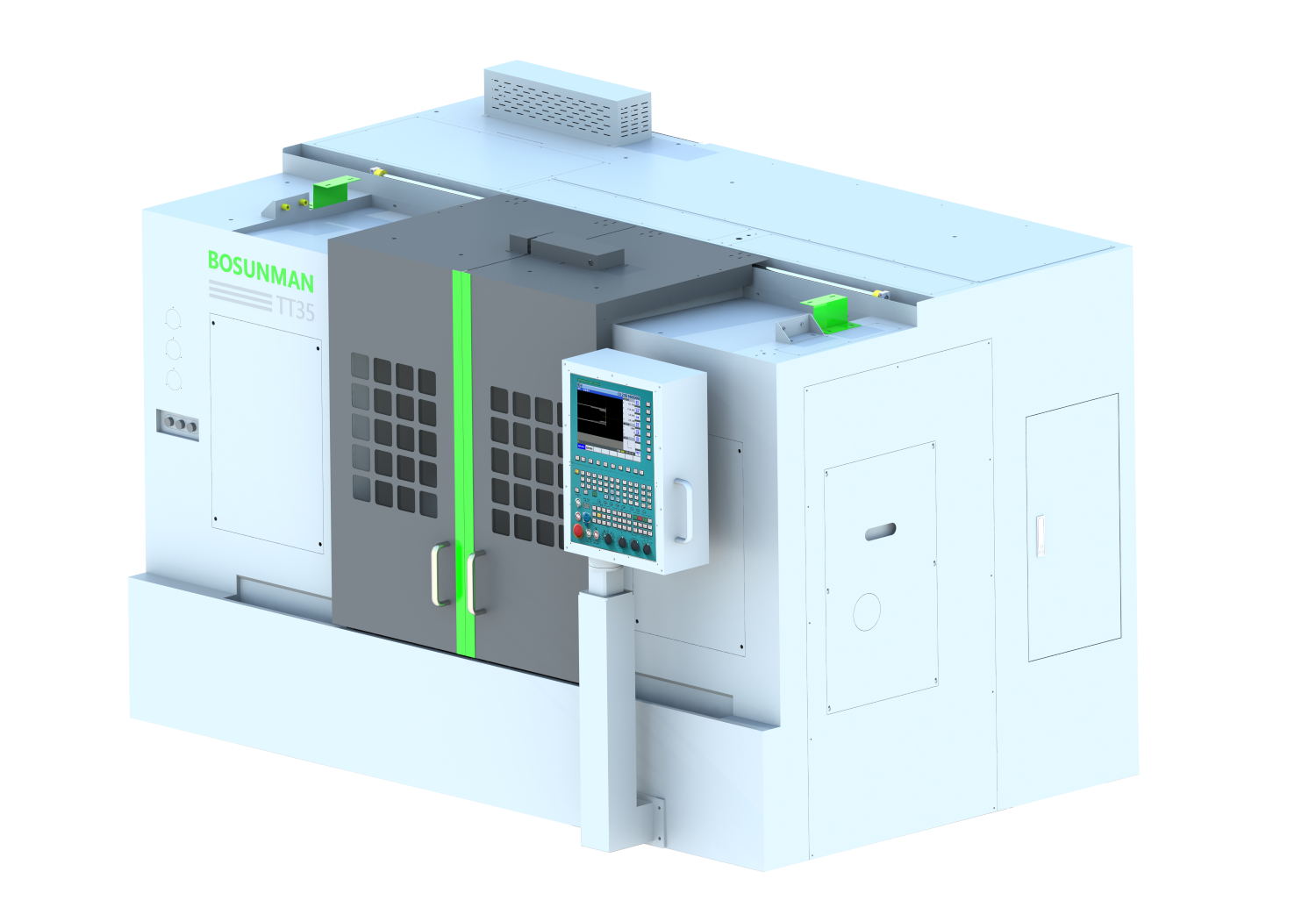

ZK21 E Series Machine Overview (Horizontal Gun Drilling Machine)

The machine is designed as a horizontal layout. The main machine identity is the workpiece clamping and drilling rod feeding system of left and right bodies, whose ends are connected by screws and locating pins. The workpiece is clamped by hydraulic chuck and hydraulic center frame. The basic parts are HT300 precision casting, and the drill rod feeding adopts rolling guide and ball screw.

Main Features of the Machine: 1. Workpiece traversing mechanism;

2. Workpiece spindle with rotary and CNC indexing functions.

It is mainly used for the machining of large long shaft parts. In addition to concentric holes, eccentric holes and indexing holes can also be processed by the corresponding traverse mechanism and CNC indexing. One clamping, can complete the processing of multiple holes. When machining concentric holes, the workpiece spindle can be rotated to improve the skewness of the machined holes. When machining eccentric holes, the workpiece spindle is locked with an electromagnetic clutch. When machining multiple holes on the same indexing circle, the hole position is accurately positioned by CNC indexing of the workpiece spindle. The hydraulic system is placed in parallel with the main machine tool, the overall structure is compact and easy to operate. Equipped with automatic chip removal, filtering device (magnetic, paper belt, mesh, magnetic bar filtering) and oil temperature cooler, the filtering precision can reach 20μm.

Drill Rod: Frequency control, rotating and feeding, full protection on one side of the drill rod.

Workpieces: Rotary; traverse; CNC controlled, indexed at any angle.

Guide bush: The left end of the workpiece is clamped with a hydraulic chuck center stand and the right end is supported by a hydraulic center plus. Hydraulic chuck and center frame can be traversed separately for machining eccentric holes.

Suitable for processing workpieces: Hydraulic bracket structural parts, cylinders, etc. or concentric and eccentric holes for shaft parts.

Structural Performance Characteristics:

- It adopts horizontal split bed structure and linear guideway;

- The drilling rod spindle adopts GSM series high precision mechanical spindle with good shock resistance and long life;

- The shank of gun drill adopts side-fixed collet, which is reliable for clamping, easy to adjust and stable in precision;

- The vibration damping support of the gun drill adopts the vice-rail and quick-change structure, which is quick and easy to adjust;

- Hydraulic chuck and self-centering hydraulic C-center frame clamping is simple and reliable;

- It can satisfy the ultra-deep hole machining of the eccentric hole of piston rod, indexing hole of cylinder cylinder wall, and center hole of live column, and the machining range is wider;

- Processing adopts gun drill cutting, equipped with high-pressure cooling and filtering system, fast efficiency and high precision;Technical

Technical Parameters

Search

Search